Infineon IGBT modules boost efficiency in Goldwind turbines

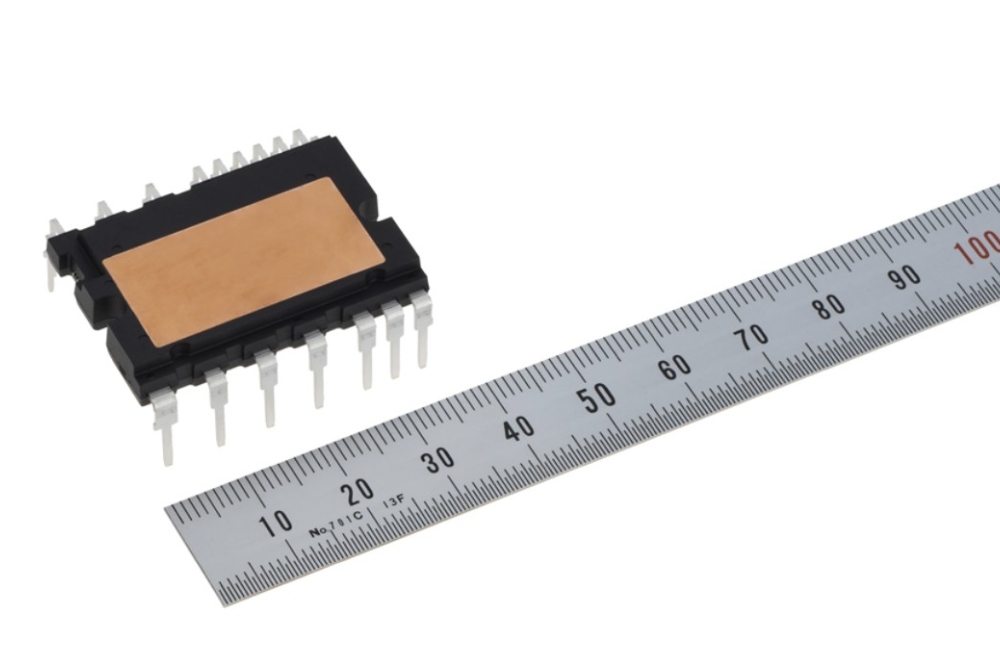

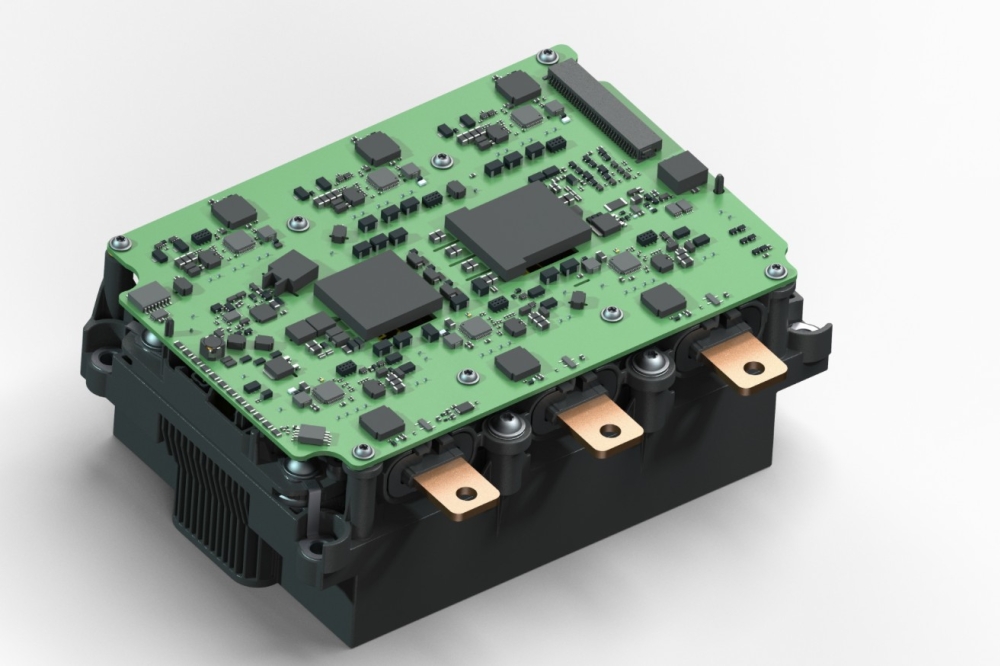

Infineon has announced it will supply Goldwind with its XHP 2 1700 V IGBT5 power modules with .XT technology that will enhance energy efficiency in Goldwind’s grid-forming GW 155 - 4.5 MW wind turbines.

This is part of a longstanding collaboration between the companies beginning in 2007.

Grid-forming wind turbines act as stabilisers within the energy grid. Unlike conventional turbines that passively follow the grid, the grid-forming technology allows wind farms to mimic the stabilising properties of traditional rotating generators.

“The emergence of grid-forming wind turbines enables wind farms to evolve from simple power suppliers into stabilising pillars of the energy grid.” said Ye Jiqiang, VP of the Wind Power Industry group and general manager of the supply chain center at Goldwind. “We look forward to further deepening our long-term collaboration with Infineon, leveraging efficient and reliable cutting-edge technology to advance renewable energy systems.”

“Collaborating with Goldwind to support their grid-forming wind turbines underscores Infineon’s commitment to strengthening global energy systems and further advancing renewable energy integration,” said Dominik Bilo, executive VP and chief sales officer industrial & infrastructure at Infineon. “Together, Infineon and Goldwind are driving decarbonisation by enhancing the reliability and efficiency of wind power generation.”

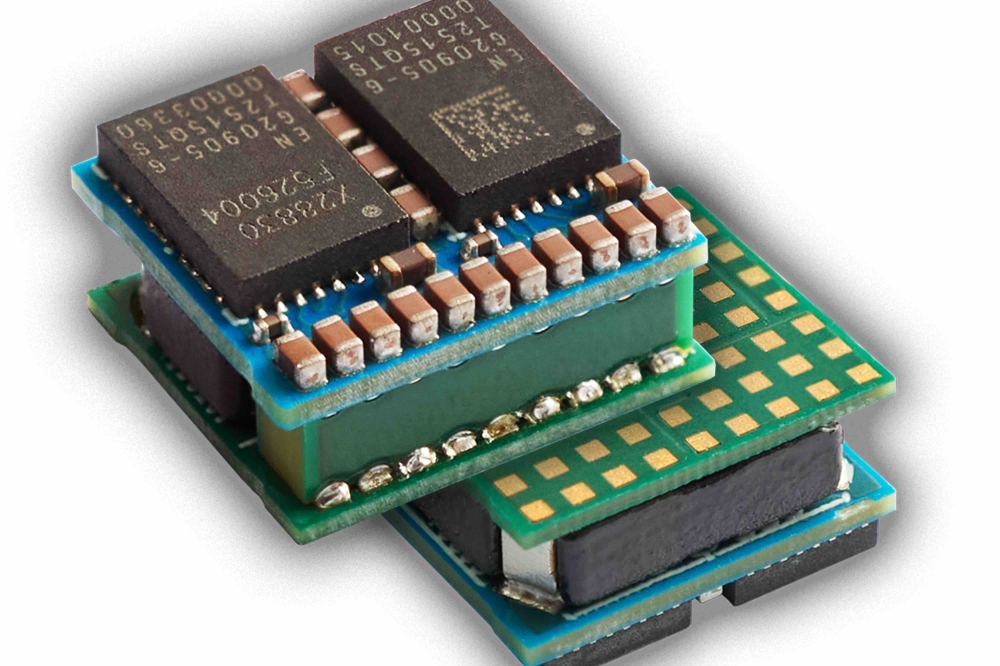

Infineon’s XHP 2 1700 V IGBT5 power modules use the .XT interconnection technology. This technology is characterised by improved wire bonding, reliable chip attachment, and high-reliability system-soldering, enabling power modules to support increased cycling loads at higher temperatures compared to standard joining technology.

The power modules feature low stray inductance and a design well-suited for paralleling, simplifying development for customers and enabling greater flexibility for platform upgrades. They provide exceptional lifetime even under challenging operating conditions such as those in wind turbines. As a result, they minimise unplanned downtimes and maximise wind energy harvested. Today, Infineon products are used in every second newly installed wind turbine worldwide.