Thermally conductive silicones

From electric vehicles (EVs) and electric bikes (e-bikes) to trucks and buses, demand for e-mobility solutions is rising.

By Luc Dusart, marketing manager for Mobility & Transportation Electronics at Dow

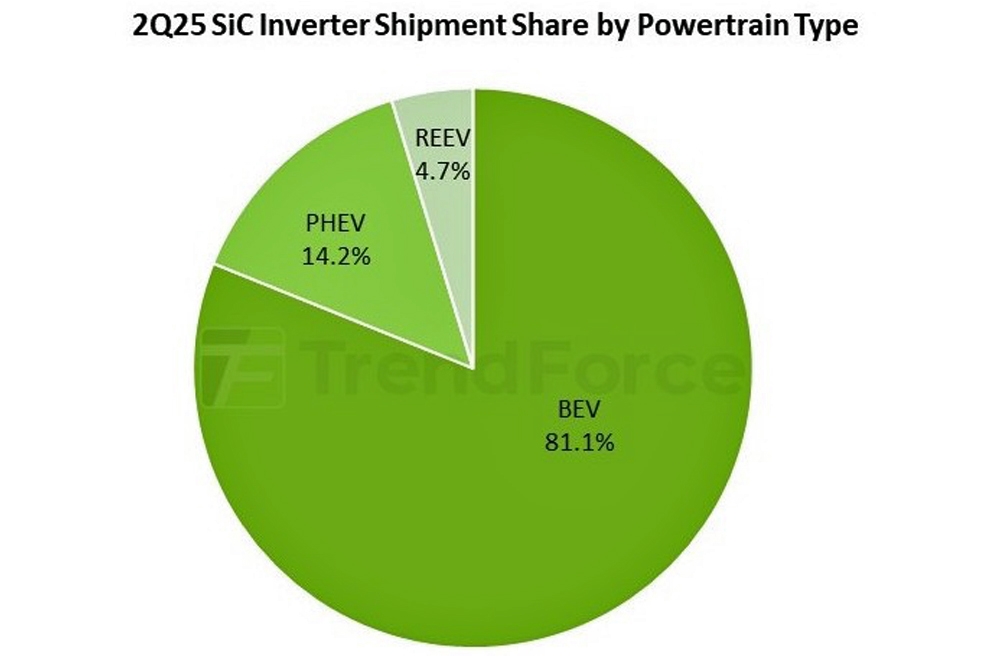

According to the International Energy Agency (IEA), the global EV fleet is expected to grow 12-fold by 2035. Current and evolving e-mobility solutions depend on advances in power electronics that facilitate effective conversion and control of increasing amounts of electrical energy. E-mobility goals such as greater range and performance require new power electronics devices with higher efficiency, smaller formats and better thermal management properties. However, several factors present roadblocks to achieving these improvements. Advanced silicone-based materials can help address these challenges.

Managing heat, boosting reliability and streamlining production

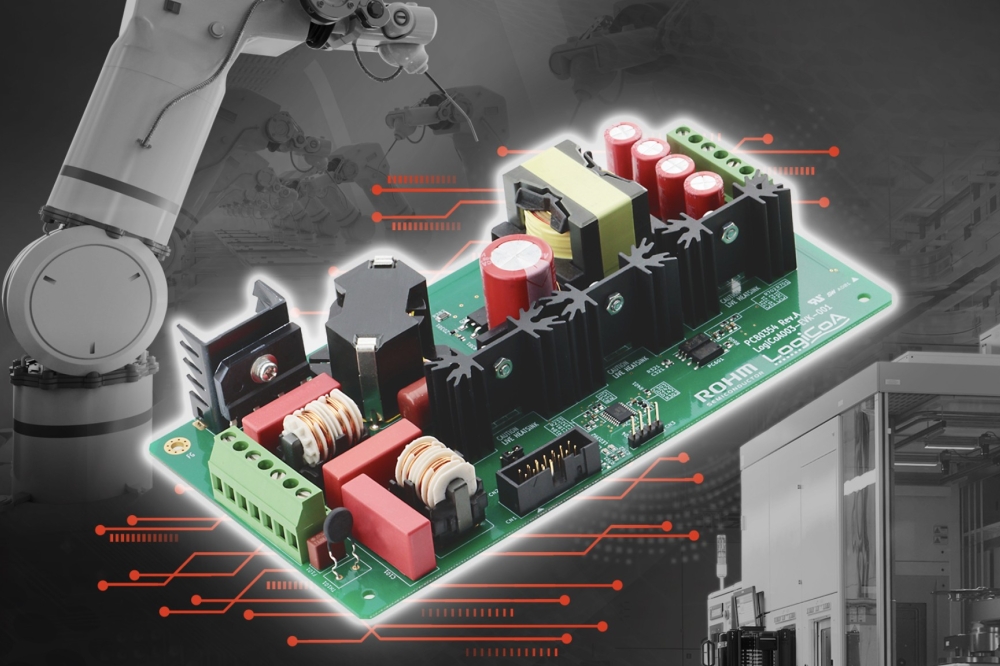

When designers add more, and increasingly powerful components to printed circuit board (PCB) assemblies used in signal flow and power transfer, their additional generated heat can reduce the capacity, lifespan and performance of power electronics devices. Excessive heat can also increase the risk of thermal runaway in battery cells. These are two reasons why designers are seeking e-mobility materials, such as thermally conductive silicones, that can resolve heat-related issues with better thermal management.

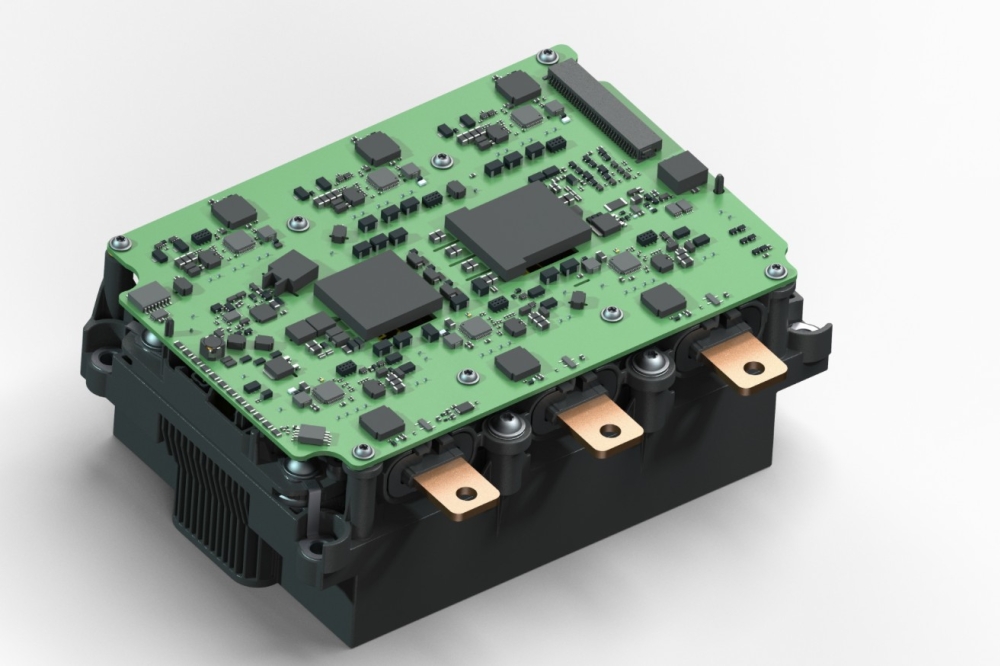

Designers are also looking for solutions to performance, safety and reliability concerns. For example, e-mobility power electronics applications like electronic control units (ECUs), inverters, converters and onboard chargers face environmental and mechanical challenges. Resistance to moisture, humidity, salt spray, shock and vibration is critical for e-mobility technologies that operate on roads or railways. Moisture, humidity and salt can lead to corrosion in PCB traces, while shock and vibration can cause solder joints to crack and PCB substrates to warp or bend.

There are also assembly issues to consider. Manufacturers of mass-produced e-mobility technologies such as EVs prefer materials that help facilitate high-volume production. For example, silicone-based materials can be applied quickly and precisely with automated mixing and dispensing equipment to reduce cycle times, labor costs and material waste. When curing is required, a material’s curing method can also affect cycle times and operational expenses such as energy costs.

Advantages of advanced silicones

For thermal management, assembly and protection of electronic components, E-mobility designers have a choice of materials including silicone-based solutions and organics such as epoxies and urethanes. Compared to organics, advanced silicone-based materials provide important advantages. For example, silicones withstand higher temperatures than organics and provide longer-lasting heat resistance without a significant loss in mechanical properties.

Temperature fluctuations also pose a challenge for e-mobility power electronics. When materials used in PCB components have different coefficients of thermal expansion (CTEs), they expand and contract at different rates. Advanced silicones can absorb some of the stress that results from inconsistent temperature changes. By contrast, epoxies and urethanes may crack because they have a higher modulus than silicones and relieve stress less effectively, due to their rigidity after curing.

With their low modulus, silicones can also absorb shock and vibration associated with operating an e-bike or EV. As mentioned previously, epoxies and urethanes are prone to cracking under stresses such as vibration. The hydrolytic stability of advanced silicones is also an advantage because it helps protect EVs from moisture related damage.

For productivity, silicones support high-volume, automated assembly and can cure at room temperature or with ultraviolet (UV) light instead of energy-intensive ovens. Dual-cure systems combine UV light with moisture to reach shadowed areas.

While epoxies and urethanes also support automated assembly and various curing methods, they cannot match silicones’ other advantages.

Silicones offer a range of benefits for power electronics and one particularly beneficial application is thermal management. To leverage the benefits of these materials in thermal management, silicone materials are supplied in a variety of formulations and formats.

Thermally conductive silicones

Thermal conductivity (TC) is measured in Watts per meter Kelvin (W/m·K). Because air has a relatively low TC of 0.024 W/m·K, it is not efficient at dissipating heat from electronics. Therefore, filling the air gaps between heat sinks or heat spreaders and other components and substrates with a thermally conductive material is essential to optimize heat dissipation.

Silicones are inherently thermally insulating; however, with the addition of specialized fillers they can become thermally conductive. By conducting heat from power electronics, these silicones help prolong the life of power electronics, reduce energy consumption and prevent damage to surrounding components on a PCB. Depending on the application, operational requirements and preferred dispensing method, manufacturers can choose from silicone gap fillers, gels, greases/compounds, adhesives, and encapsulants.

• Gap Fillers: Thermally conductive silicone gap fillers fill large gaps (0.5-5mm) between components on a PCB. These materials are available with a wide range of thermal conductivity values up to 12 W/mk. Some applications mayneed materials with a TC of 6 W/m·K, while other electronics may require a higher or lower TC.

• Greases: Thermally conductive silicone greases create a path between a heat source and a heat spreader. They are easy to dispense with automated equipment and do not require curing. These materials come in a range of thermal conductivities. Applications include heat dissipation from insulated-gate bipolar transistors (IGBTs) used with inverters. Importantly, thermally conductive silicone greases support thin bond lines for improved heat transfer.

• Adhesives: Thermally conductive silicone adhesives bond electronic components within a heat-generating assembly such as an ECU. They also are used to bond metal heat sinks to PCB substrates. They are available in one- and two-part formulations that are easy to dispense and can cure at room temperature. Thermally conductive silicone adhesives have TC values that range from 0.8 to 3.3 W/m·K.

• Gels: Thermally conductive silicone gels are highly conformable and reworkable, making them especially valuable for complex geometries of some e-mobility power electronics. These materials also have significantly lower viscosities than

other thermally conductive products such as gap fillers because of their semi-solid state. Low viscosity makes gels easier to pump and mix, and flow more freely. Thermally conductive silicone gels cure at a wide range of temperatures and are

easy to process.

• Encapsulants: Thermally conductive silicone encapsulants can cure at room temperature or with added heat. They flow easily and, after mixing, have viscosities ranging from 3,000 to 25,000 millipascal second (mPa·s). Products with a TC from1.0 to 4 W/m·K are available.

Applications include battery chargers where the small feature size of on-board-charger inductors need to be filled to ensure efficient heat transfer.

Other advanced silicone products

Unlike thermally conductive silicones, thermally insulating silicones prevent or reduce the spread of heat due to their low thermal conductivity and unique molecular structure. Some also meet specific flame ratings or provide electrical conductivity and shielding against electromagnetic interference (EMI).

As designers add more electronics to e-mobility vehicles, EMI shielding is becoming increasingly important because electronic noise or crosstalk can affect performance and safety.

Thermally insulating silicone products for e-mobility applications include encapsulants, conformal coatings, adhesives and greases.

• Silicone Encapsulants play a crucial role in protecting inverters, converters and e-motors from various environmental and operational hazards. They are also used with IGBT modules, high-voltage resistor packs, sensors, connectors, wires and LED lighting. These advanced silicone materials are waterproof, stress relieving, electrically insulating, vibration damping and flame resistant. Transparent silicone encapsulants also provide visibility of protected electronics during inspection or repair.

• Silicone Conformal Coatings are thin films that are applied to PCB substrates in one or more layers to resist moisture, dust, abrasion and mildew. Depending on their formulation, these materials may have UL94 V-0 or UL94 V-1 flame rating. Silicone conformal coatings are used in the automotive industry to replace potting or encapsulating materials that result in a brick-like structure, which can be bulky and heavy. By using conformal coatings instead, e-mobility designers can support light weighting without sacrificing performance.

• Silicone Adhesives are a broad category of materials with variations that are thermally insulating. They are used for assembly of inverters, converters, on-board battery •chargers, e-motors and ECUs. Thixotropic silicone adhesives, featuring a thick, paste-like consistency, are used for gasketing, typically as lid seals or covers. Silicone adhesives with high tensile strength are recommended for e-mobility applications that need to resist significant pulling forces, such as power electronics that are

subjected to significant vibrations. Another option is adhesive sealants, which combine strong bonding with reliable sealing. These are well suited for e-motors due to a combination of their chemical, thermal, and mechanical properties. Silicones can withstand extreme temperatures, they are excellent electrical insulators and their elasticity help absorb shocks and vibrations, reducing wear and tear on components.

• Electrically conductive silicone Adhesives can be used in several formats such as a die attach adhesive, EMI gasketing, and grounding adhesives to maintain electrical connection. Depending on the application the EC silicone can provide electrical connection across a wide range of application temperatures and over a wide variety temperature, both low and high. of The EMI shielding provided by electrically conductive silicone adhesives can protect sensitive e-mobility electronics across frequencies in the 1 KHz to 70 GHz range.

• Silicone Greases can provide thermal protection but may also be used for protection against electrical arcing and voltage drop. Such dielectric greases protect electrical connections from dirt, water, moisture and contaminants.

Importance of the right supplier

Finding the right materials for e-mobility power electronics is only part of any solution.

Partnering with a leading supplier can help designers improve e-mobility performance, reliability, safety and durability. Dow takes a collaborative approach to help customers advance e-mobility technologies.

Hands-on collaboration is paired with Dow’s scientific research, data generation and testing under real-world conditions to ensure quality and reliability of silicone-based products.

By leveraging advanced silicones and support services, designers can confidently drive innovation in power electronics and shape the future of e-mobility.