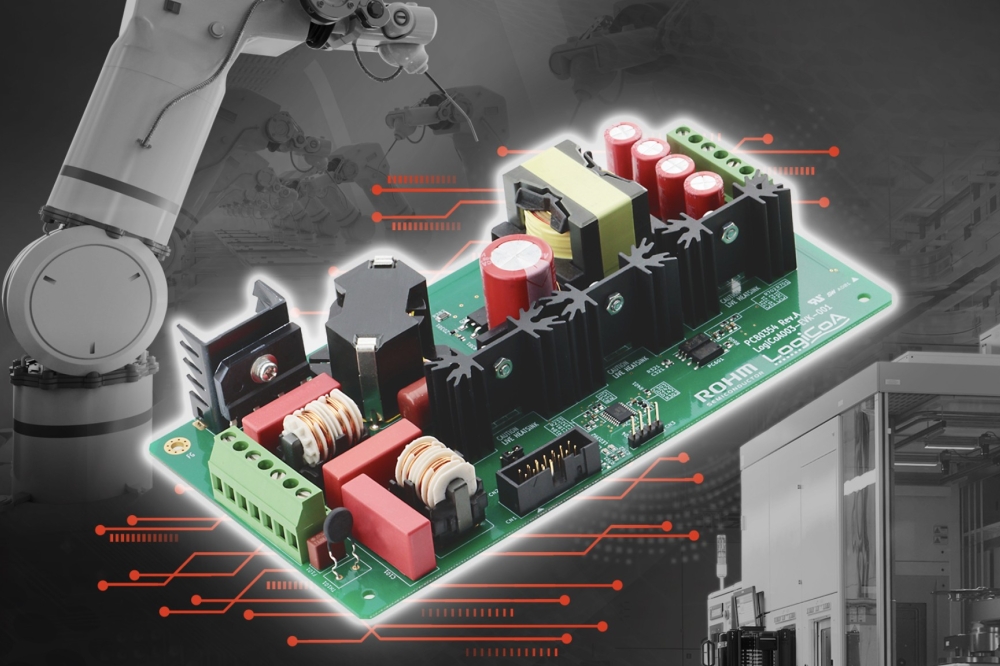

QPT launches test platform for GaN-based motor drives

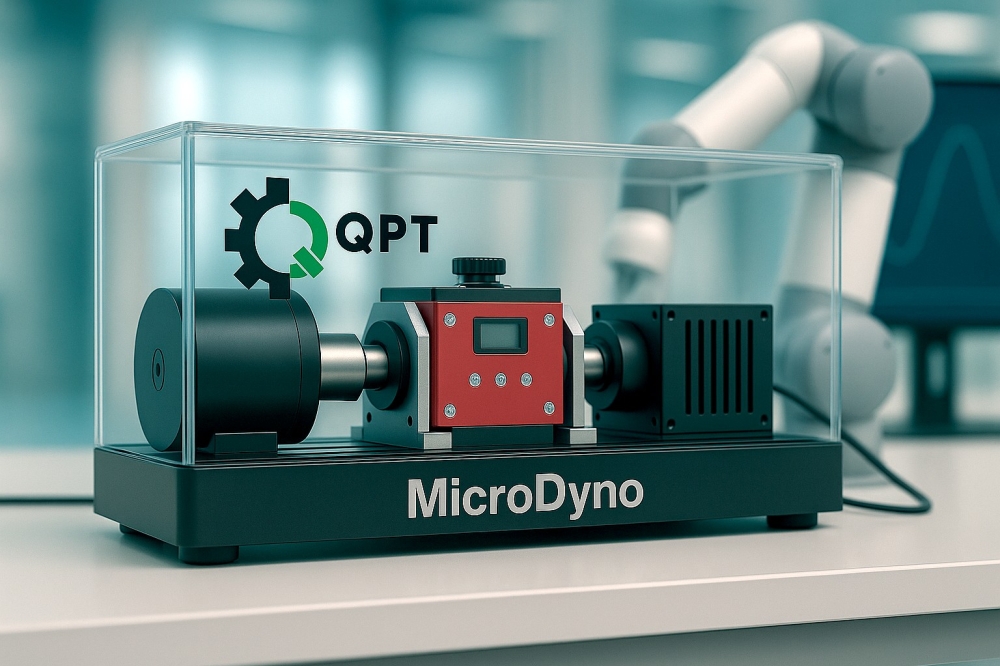

QPT has unveiled MicroDyno, what it describes as a breakthrough low-voltage motor drive test platform which demonstrates the key benefits of ultra-high frequency GaN-based motor drives.

Operating at 1 MHz switching speeds, MicroDyno integrates a compact filter to deliver a true sine wave voltage to motors, a capability that fundamentally differentiates it from existing low-frequency PWM-based systems, according to the company.

Rob Gwynne, CTO and founder of QPT, commented: “MicroDyno shows what becomes possible when you combine ultra-fast GaN switching with intelligent filtering. For robotics, we’re not just improving smoothness. We can now dynamically correct torque ripple and cogging in real time, something that even expensive encoder-based systems cannot do to this level of precision. This opens the door to more precise, more compact and more reliable robots at a much lower system cost.”

Simon Hart, director and CTIO of InnCat commented: “Even the best servos can have horrid cogging torque. I have spent much time with fast control loops and torque compensators to get the required speed smoothness. And then loop responses drift over time!”

New standard for robotic drives

Most current robotic drives operate at 4–16 kHz PWM frequencies, shaping current into a sine wave but leaving the voltage at the motor as high dv/dt PWM. Some specialist systems reach 100 kHz, but these face electromagnetic challenges and are still too low frequency to enable small, cost-effective filtering required for true sine voltage output and EMI filtering.

QPT says that MicroDyno breaks this barrier. By extracting the maximum performance from GaN transistors, it is able to operate at around 100x the standard frequency which enables a very small, cheap output filter, producing a clean sine voltage directly at the motor terminals with an extremely high signal-to-noise ratio. This also eliminates EMI, reduces bearing currents, enables “sensing without sensors”, and allows the use of unshielded cables or a fully integrated motor drive — a transformative shift for robotics integration.

This is coupled with small size (1 MHz switching reduces filter and drive size, enabling the motor drives to be fully integrated with the motors in the robotic joints) and the ability to use it with AI for next-generation designs to further improve the performance and also monitor and optimise across a fleet of electric motor systems.

MicroDyno demonstrates QPT’s architecture at 48V for robotics and cobots, but the underlying technology is fully scalable to higher voltages, according to QPT. Using the company's qAttach packaging, the same high-frequency sine-wave advantages extend to 400V and 800V systems — opening paths to deliver significant benefits in industrial automation, HVAC, and electric vehicle traction drives.