NREL team constructs record-beating SiC module

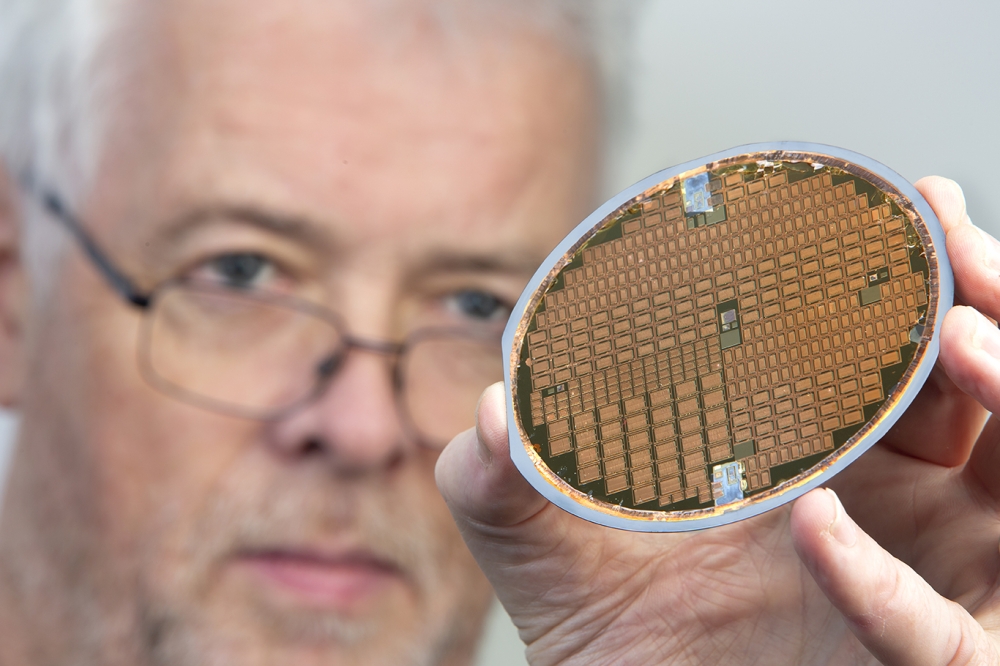

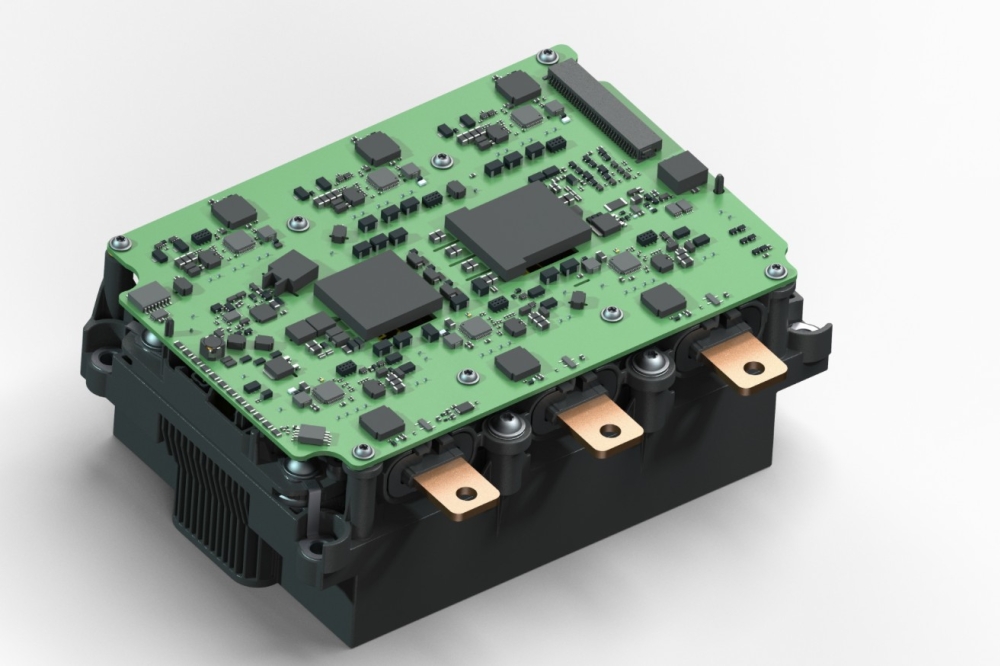

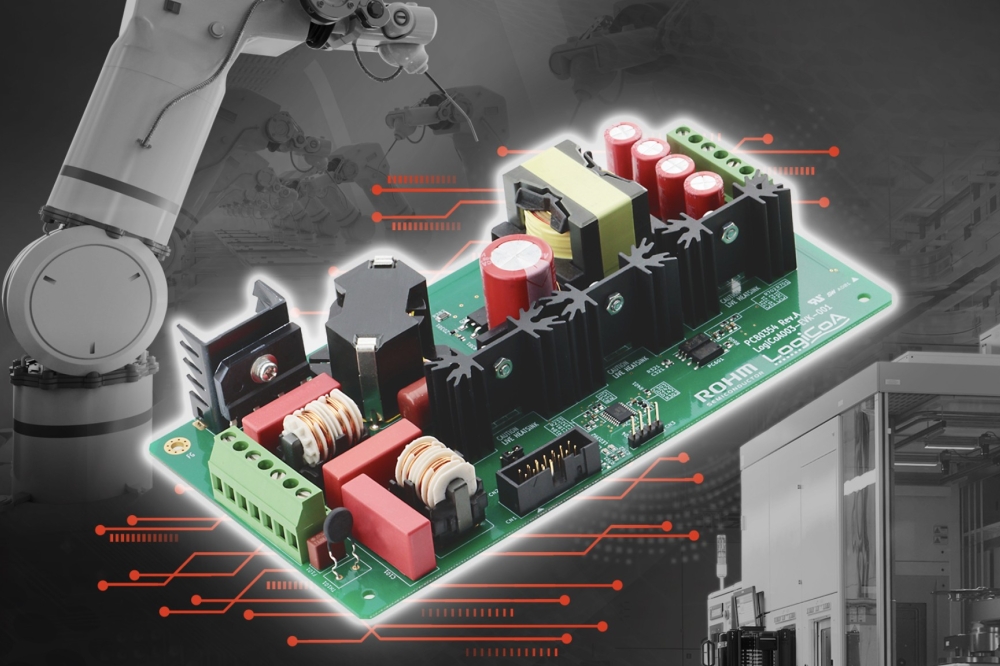

NREL has developed an Ultra-Low Inductance Smart (ULIS) SiC power module with a parasitic inductance seven to nine times lower than any current state-of-the-art SiC power module.

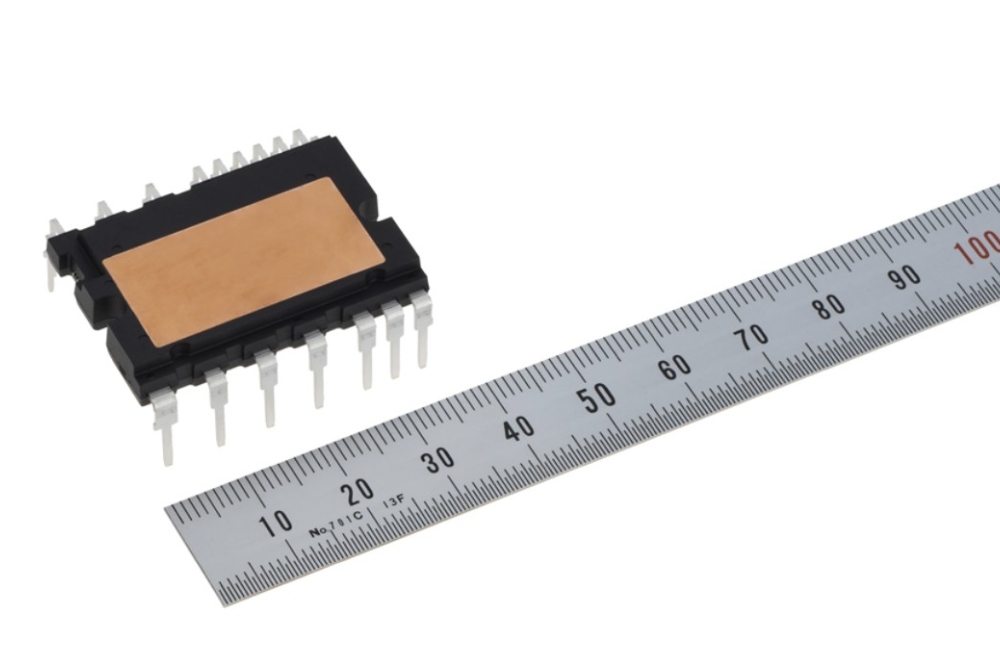

The 1200V, 400A module is capable of achieving five times greater energy density than predecessor designs in a smaller package, making it possible for to build and power more efficient, compact, and lighter technologies for applications such as data centres, power grids, microreactors, and even heavy-duty vehicles such as next-generation aircraft and military vehicles.

“We consider ULIS to be a true breakthrough,” said Faisal Khan, NREL’s chief power electronics researcher and the principal investigator for the project. “It’s a future-proofed, ultrafast power module that will make the next generation of power converters more affordable, efficient, and compact.”

Furthermore, Khan explained, ULIS is uniquely suited for high-intensity applications, like aviation and military operations, because the powerful, lightweight module also monitors its own state of health and can predict component failure before it occurs.

Unlike a typical brick-like power module, ULIS winds its circuits around a flat, octagonal design. The disk-like shape allows more devices to be housed in a smaller area, making the overall package smaller and lighter. At the same time, novel current routing allows for maximum magnetic flux cancellation, contributing to the power module’s clean, low-loss electrical output—in other words, its ultrahigh efficiency.

“Our biggest concern was that the device switches off and on very quickly, and we needed a layout that wouldn’t create a chokepoint within the design,” said Shuofeng Zhao, an NREL power electronics researcher who designed ULIS’ flux cancellation architecture.

One of the original layouts, Zhao said, looked like a flower with a semiconductor at the tip of each petal. Another idea was to create a hollow cylinder with components wired to the inside. Sarwar Islam, another NREL power electronics researcher on the ULIS team, came up with the 2D structure, which made it possible to build the module balancing complexity with cost and performance.

“We squished it flat, like a pancake,” Zhao said, “and suddenly we had a low-cost, high-performing design that was much easier to fabricate.”

Where conventional power modules rely on bulky and inflexible materials, also ULIS takes a new approach. Instead of dissipating excess heat by bonding copper sheets directly to a ceramic base, ULIS bonds copper to a flexible polymer, called Temprion, to create a thinner, lighter, more configurable design.

Because the material bonds easily to copper using just pressure and heat, and because its parts can be machined using widely available equipment, ULIS can be fabricated quickly and inexpensively, according to the NREL team. Manufacturing costs total hundreds, rather than thousands, of dollars.

A further breakthrough allows ULIS to function wirelessly, as an isolated unit that can be controlled and monitored without external cables. A patent for this low-latency wireless communication protocol is pending.

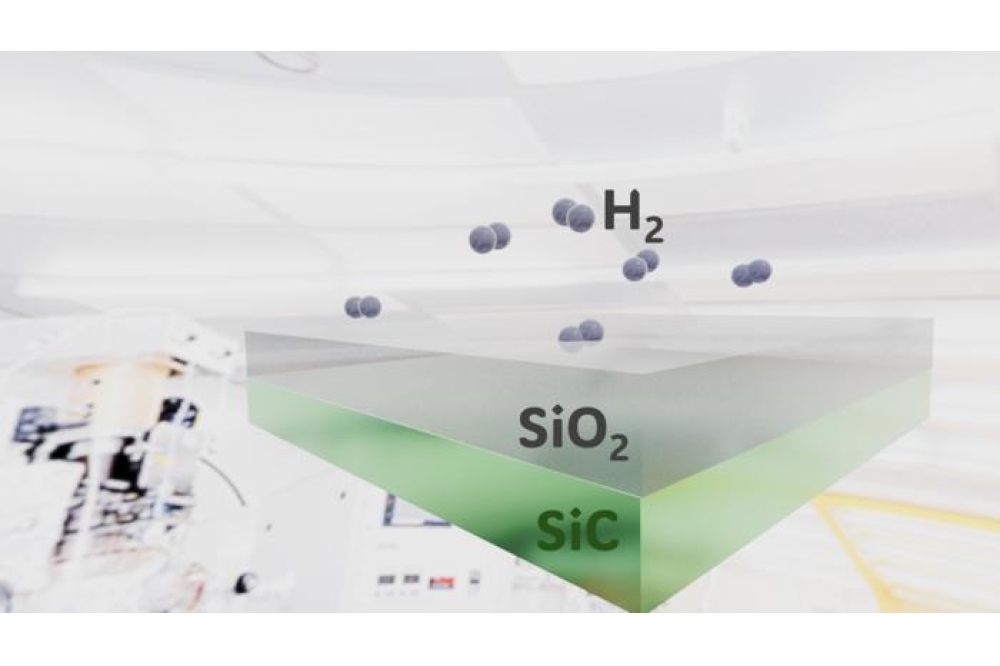

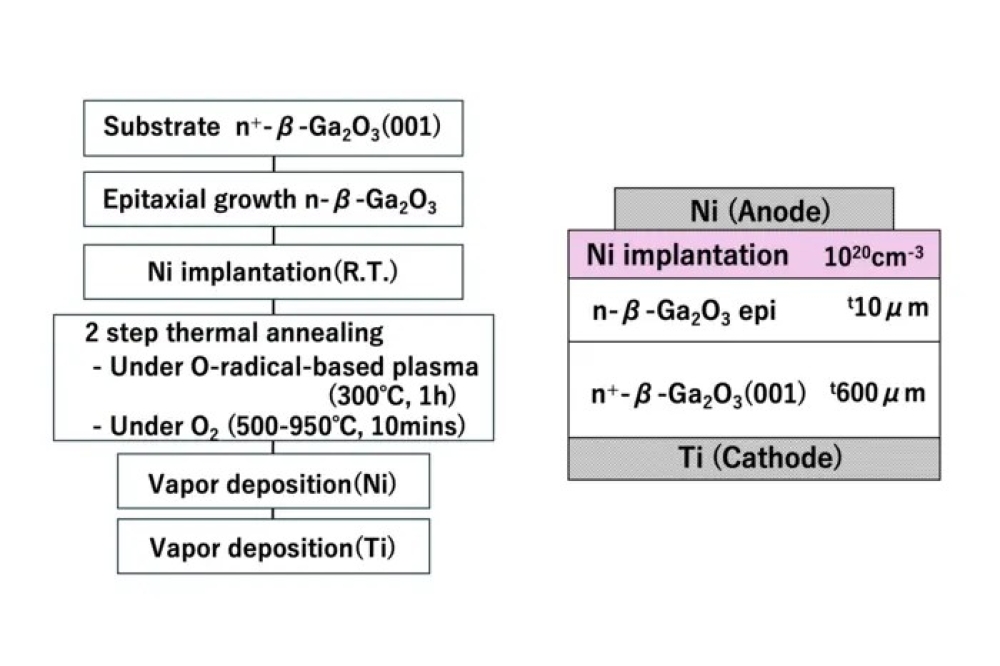

ULIS can scale to accommodate advancements in semiconductor devices using SiC, GaN, and even gallium oxide.