Japanese team prepares to make SiC from chip waste

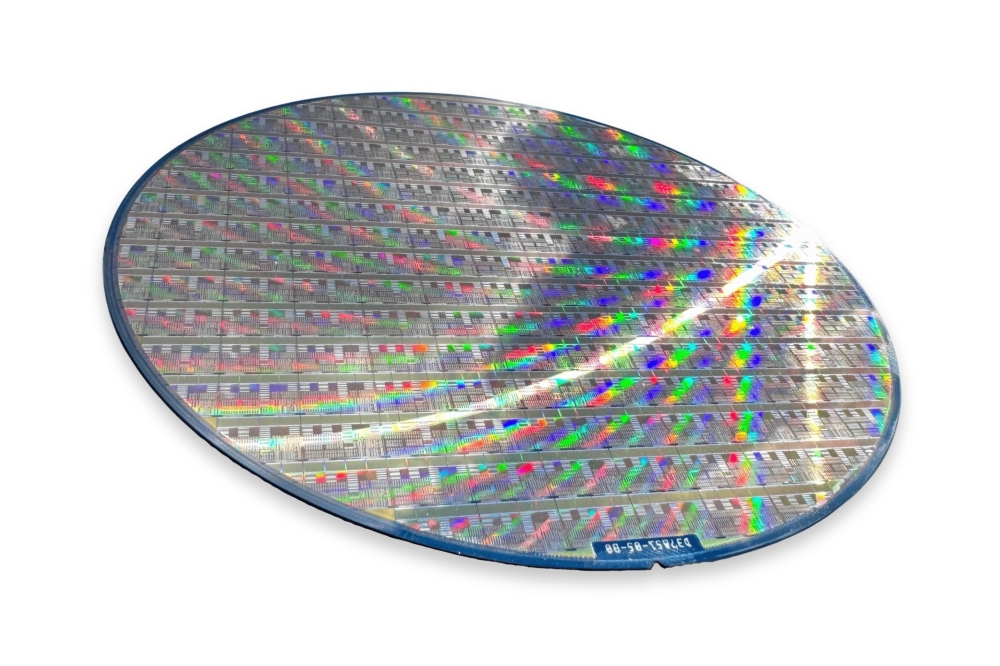

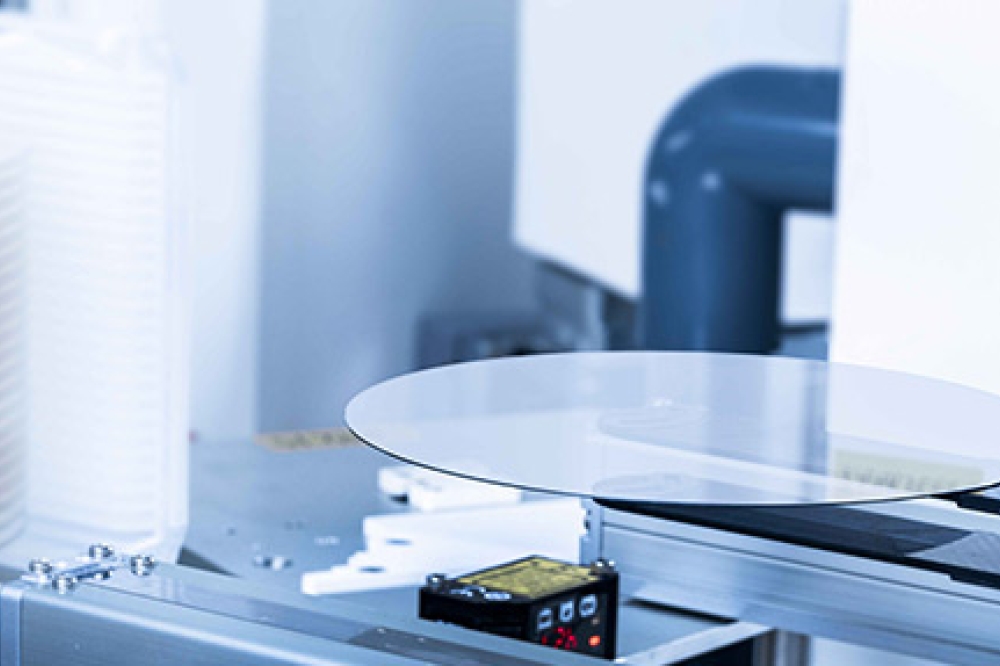

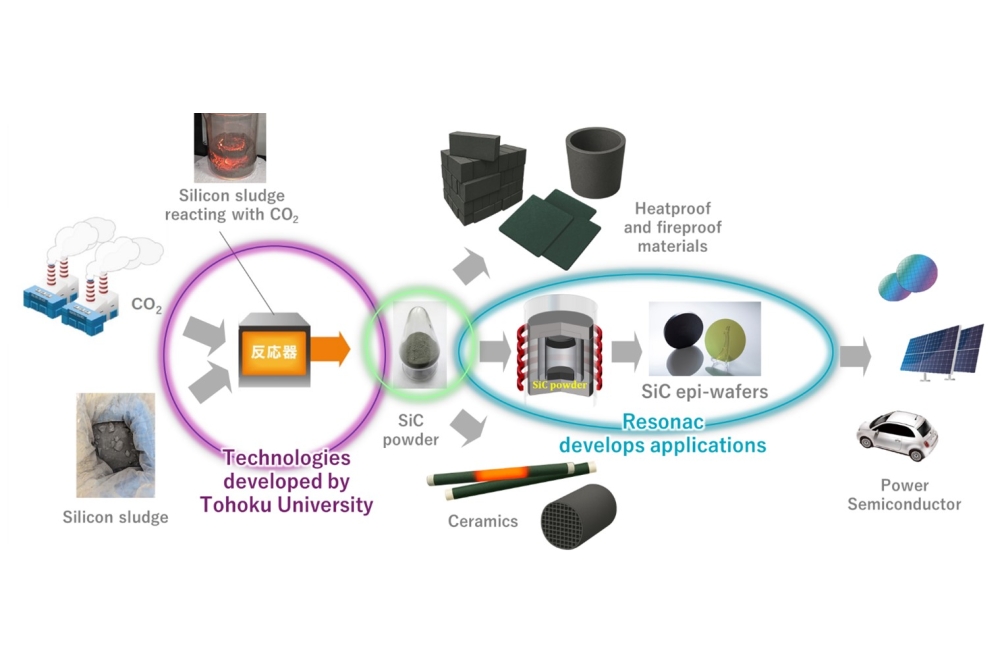

For the last year Japanese chemical company Resonac and Tohoku University have been exploring using SiC powder, produced from sludge generated during silicon wafer manufacturing and carbon dioxide, as a raw material for the growth of SiC single-crystal materials used in power semiconductors.

The team say they have now completed this basic research phase and have started full-scale studies aimed at practical applications.

According to the researchers, if this technology is successfully commercialised, SiC power semis will not only contribute to energy conservation as products but also enable reductions in CO2 emissions during manufacturing, the recycling of silicon sludge and CO2, and the overall reduction of environmental impact throughout their lifecycle.

They estimate that the CO2 reduction effect per 100 tons of SiC powder will reach the equivalent of 110 tons of CO2. This is expected to significantly contribute to the further promotion and widespread adoption of SiC power devices, which enable energy conservation and CO2 reduction.

For the fundamental research, Tohoku University synthesised SiC powder by heating silicon sludge and CO2 with microwaves at its carbon recycling demonstration research hub, while Resonac worked on applying the SiC powder to SiC single crystal substrates.

Jun Fukushima, assistant professor, department of applied chemistry, Graduate School of Engineering, Tohoku University explained more: "The key feature of this process lies in its ability to transform CO2, which is stable gas, into high-purity SiC with low energy consumption, offering a promising solution to both waste management and greenhouse gas reduction.

"Looking ahead, we aim to expand its application across diverse fields such as electric vehicles and renewable energy sectors. By accumulating practical demonstrations, we seek to enhance industrial competitiveness and present concrete measures toward achieving carbon neutrality and a circular economy by 2050."