Heat-conductive plastic could help cool power chips

Northeastern University researchers have developed a new, lightweight plastic-ceramic composite that conducts heat and can be used to more efficiently cool advanced power electronics in phones, data centres and cars.

“Managing heat is a big challenge for power electronics and devices like radar antennas,” says Northeastern Randall Erb, head of the university’s Directed Assembly of Particles and Suspensions (DAPS) Lab and lead researcher on the project. “When electronics overheat, you either have to slow them down or turn them off. That might be fine for a phone, but not for critical systems like radar.”

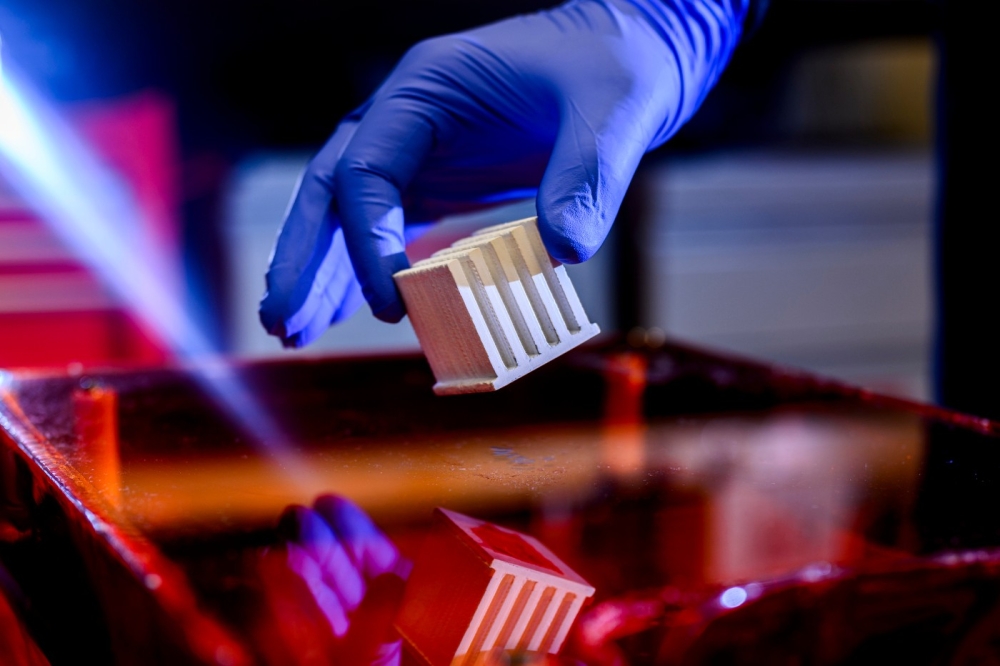

Northeastern researchers, in collaboration with the US Army Research Laboratory, developed the material that combines ceramics, polymers and additives into a 3D-printable plastic composite. It has a unique internal structure, ordered down to the nanoscale, that lets heat move through it easily.

“Plastics are normally terrible at conducting heat,” says Daniel Braconnier, a former PhD student in Erb’s lab. “Adding ceramic particles helps a bit, but the plastic still slows heat flow too much.”

The breakthrough was finding a way to precisely organise the material at every scale — from molecules all the way up to the printed part. Using 3D printing, the team carefully positioned ceramic particles, then used special heating steps to grow tiny bridges of crystalline polymer between them. This connected network allows heat to travel efficiently, making the material even more thermally conductive than stainless steel, while being four times lighter.

“These properties can enable much higher performance in many systems,” Erb says.

While metal materials like stainless steel can short out electronics if they touch them, the new material is an electrical insulator. It also doesn’t block radio frequency signals, which means it won’t interfere with 5G or radar systems.

“These new materials can cover and protect circuits without causing electrical shorts,” Erb continues. “They help pull heat away from advanced telecommunication devices without blocking their signals.”

“Industry keeps pushing for higher power in smaller packages, which means devices keep getting hotter,” Braconnier says. For example, he notes that an iPhone processor often doesn’t run at full speed in hot conditions to avoid overheating.

The team also sees potential far beyond phones.

“Data centres generate huge amounts of heat, and industry doesn’t have a sustainable solution yet,” Erb says. “Our material won’t solve it alone, but it could help by providing a better thermal interface with chips and other cooling systems.”

They’re also looking at electric vehicles, where overheating batteries can cause dangerous fires.

“Our material could be used around battery cells to spread out and remove heat, helping prevent thermal runaway events,” Erb says.

The team is now working to scale up production of the material in partnership with the US. Army Research Laboratory.