Scientists identify new material for wearable devices

Queensland University of Technology (QUT) researchers have identified a new material which could be used as a flexible semiconductor in wearable devices by using a technique that focuses on the manipulation of spaces between atoms in crystals.

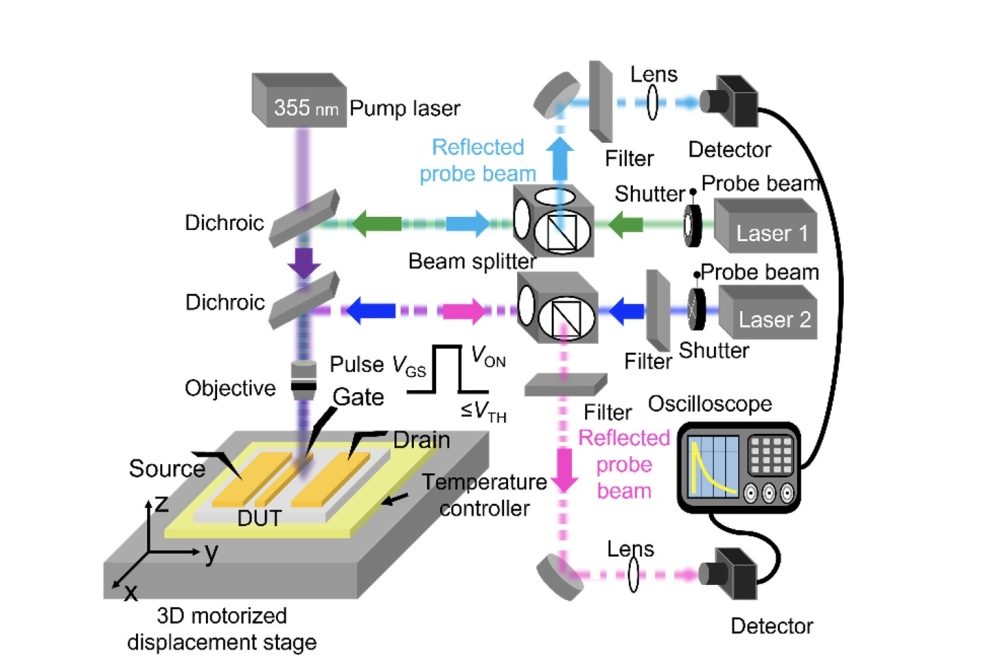

In their study published in the journal Nature Communication, the researchers used 'vacancy engineering' to enhance the ability of an AgCu(Te, Se, S) semiconductor, to convert body heat into electricity.

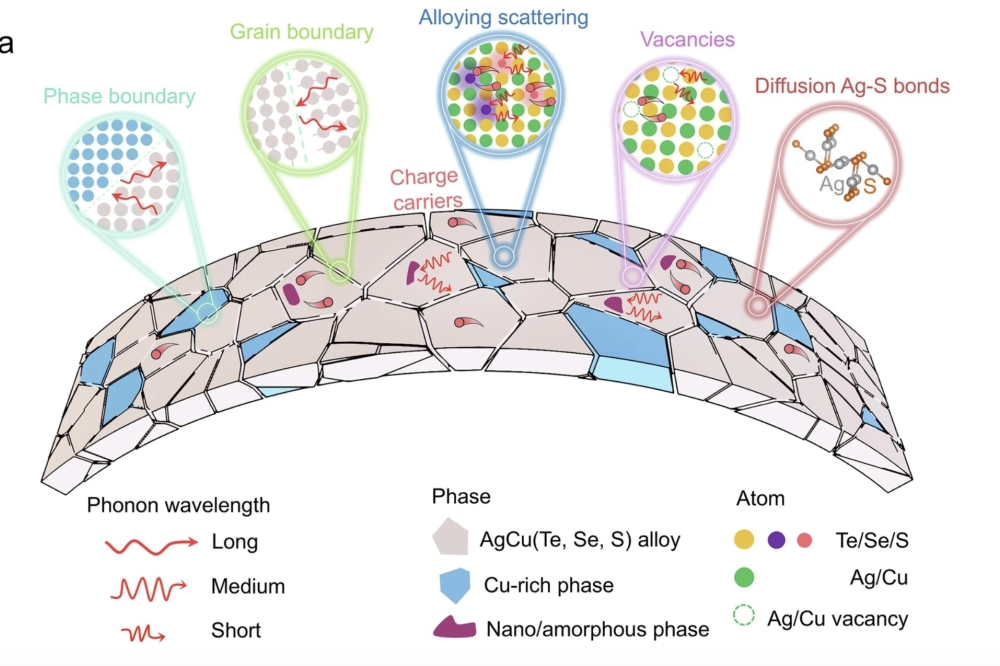

Vacancy engineering is the study and manipulation of empty spaces in a crystal where atoms are missing, to influence the material's properties, such as improving its mechanical properties or optimising its electrical conductivity, or thermal properties.

The Nature Communication article 'Strategic vacancy engineering advances record-high ductile AgCu(Te, Se, S) thermoelectric' details the process in which the QUT researchers, guided by computational design, synthesised a flexible AgCu(Te, Se, S) semiconductor through a simple and cost-effective melting method.

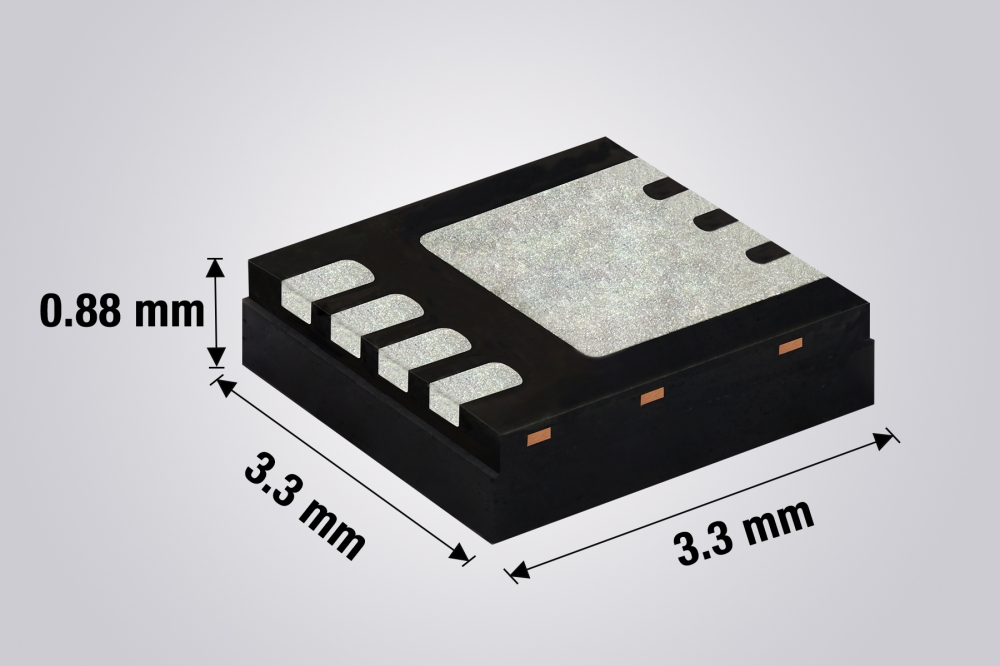

Pictured above is a schematic diagram of the microstructural characteristics of the prepared material (AgCu)0.998Te0.8Se0.1S0.1

The team found that precise control of the material's atomic vacancies not only improved its capability of converting heat into electricity, but also gave the material excellent mechanical properties, meaning that it could be shaped in different ways to adapt to more complex practical applications.

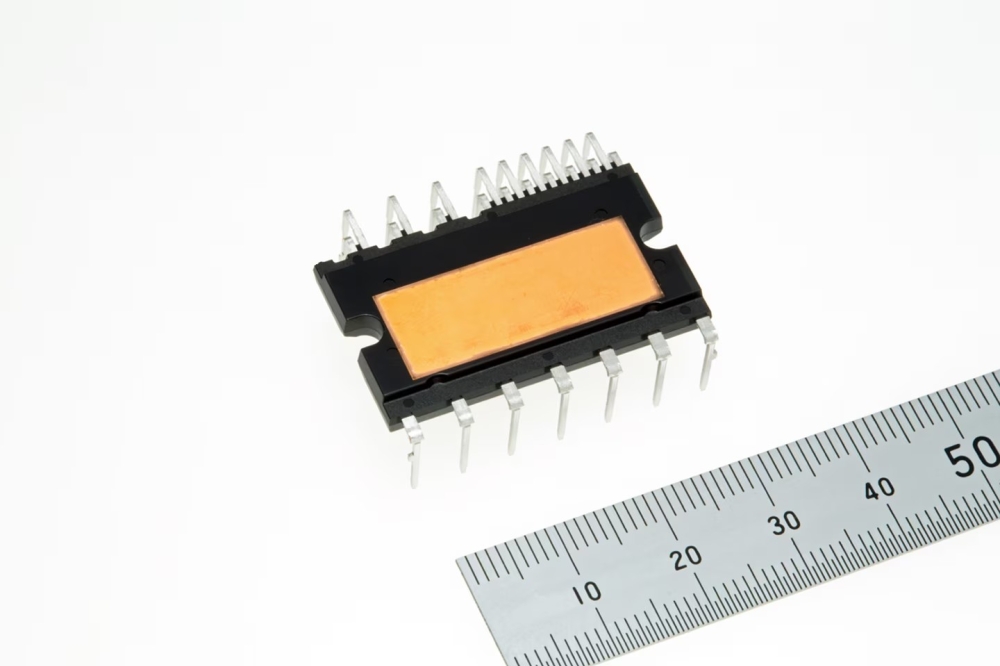

To demonstrate the practical application potential of the material, the researchers designed several different micro-flexible devices based on the material that could be easily attached to a person’s arm.

Nanhai Li, first author, said the study addressed the challenge of improving the heat-to-electricity conversion ability of an AgCu(Te, Se, S) semiconductor while still remaining flexible and stretchable, which were properties desired for wearable devices.

“Thermoelectric materials have drawn widespread attention over the past few decades in light of their unique ability to convert heat into electricity without generating pollution, noise, and requiring moving parts,” Li said.

“As a continuous heat source, the human body produces a certain temperature difference with the surroundings, and when we exercise, that generates more heat and a larger temperature difference between the human body and the environment.”

In a separate recent study published in Science, QUT professor Zhi-Gang Chen and researchers from the QUT's ARC Research Hub developed an ultra-thin, flexible film that could power next-generation wearable devices using body heat, eliminating the need for batteries. “The key to advancing flexible thermoelectric technology is to examine wide-ranging possibilities,” Chen said.

“Mainstream flexible thermoelectric devices are currently fabricated using inorganic thin-film thermoelectric materials, organic thermoelectric materials deposited on flexible substrates, and hybrid composites of both.

“Both organic and inorganic materials have their limitations – organic materials typically suffer from low performance and while inorganic materials offer better conductivity of heat and electricity, typically they are brittle and not flexible.

“The type of semiconductor used in this research is a rare inorganic material that has striking potential for flexible thermoelectric performance. However, the underlying physics and chemistry mechanisms for enhancing its performance while maintaining exceptional plasticity remained largely unexplored until now.”