CISM and Space Forge to pioneer microgravity wafer manufacture

Swansea University and Space Forge, pioneer in space-based materials manufacturing, have signed a major deal, making the company the first to be physically hosted in the Centre for Integrative Semiconductor Materials (CISM), where it will undertake cutting-edge work in manufacturing in microgravity.

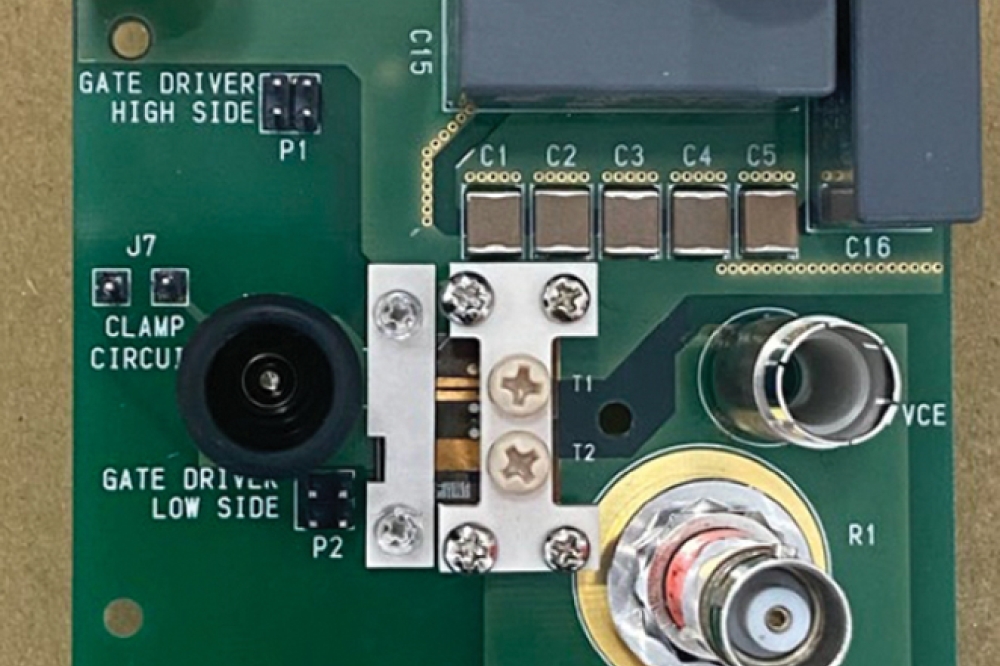

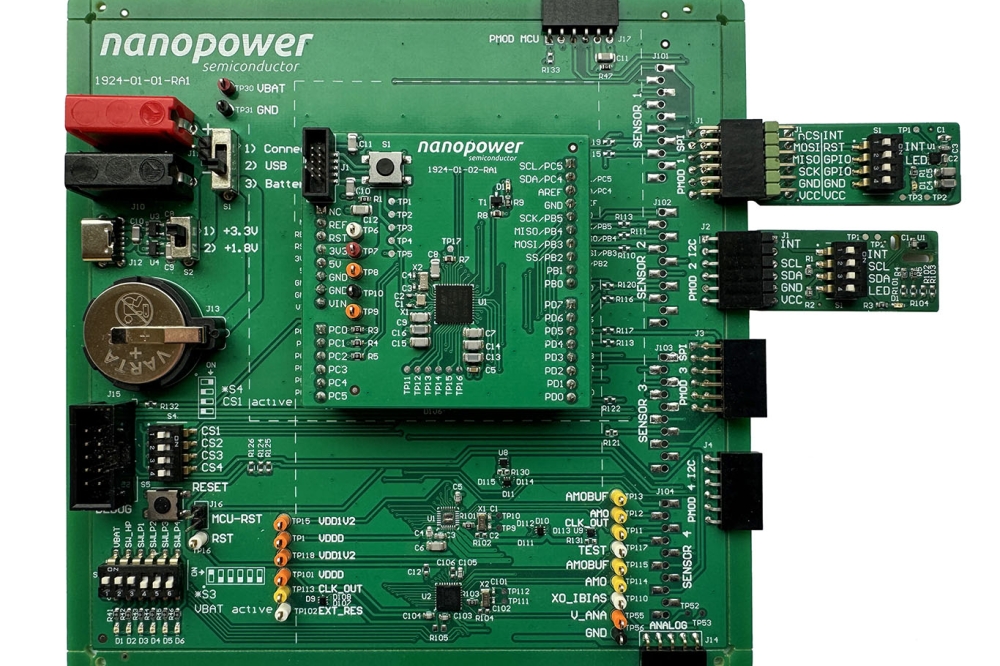

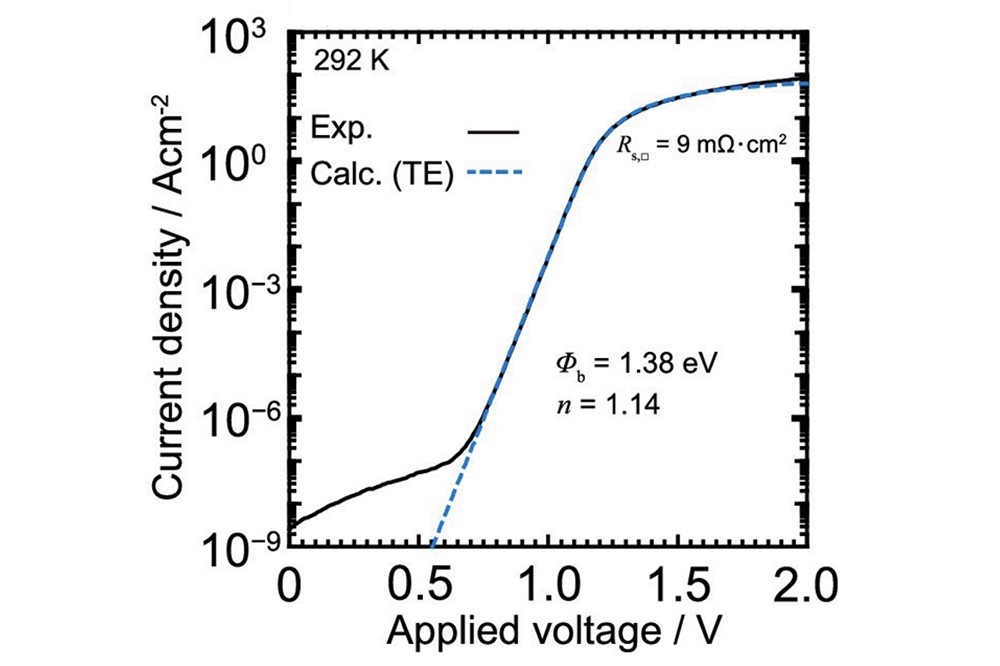

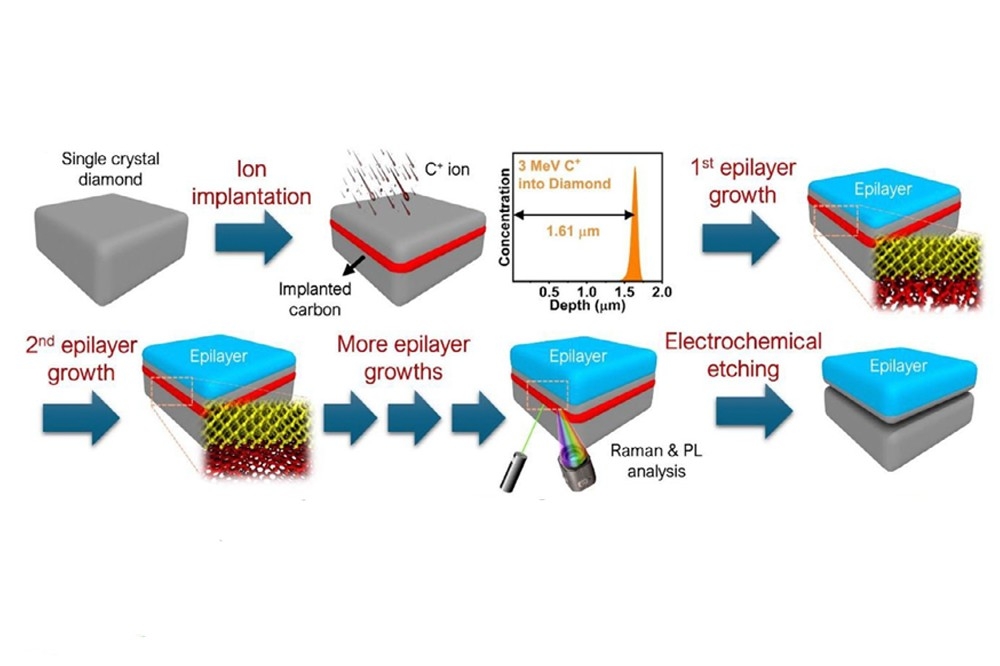

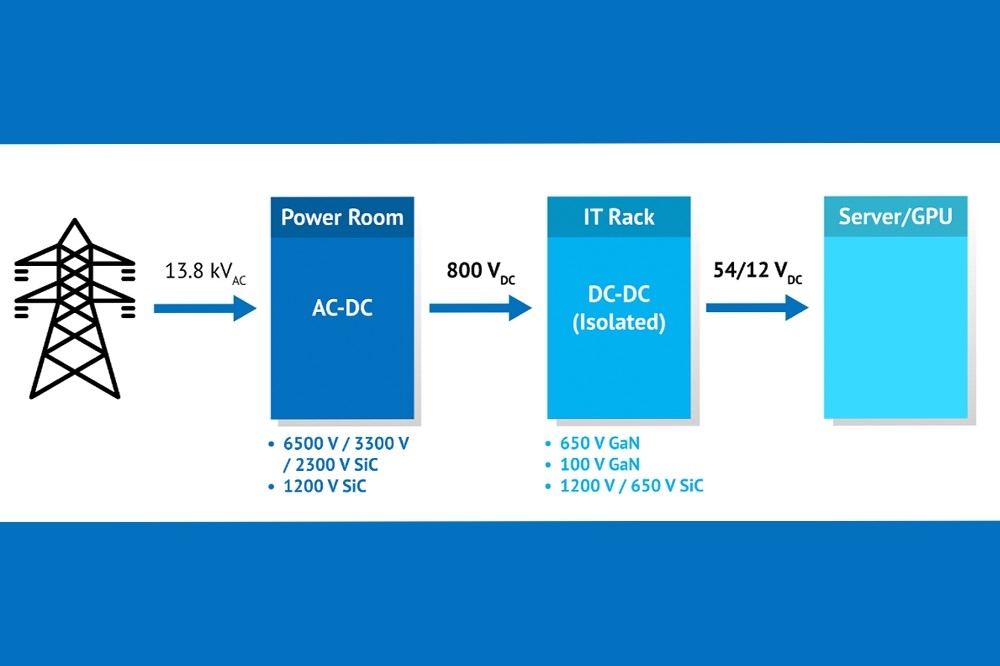

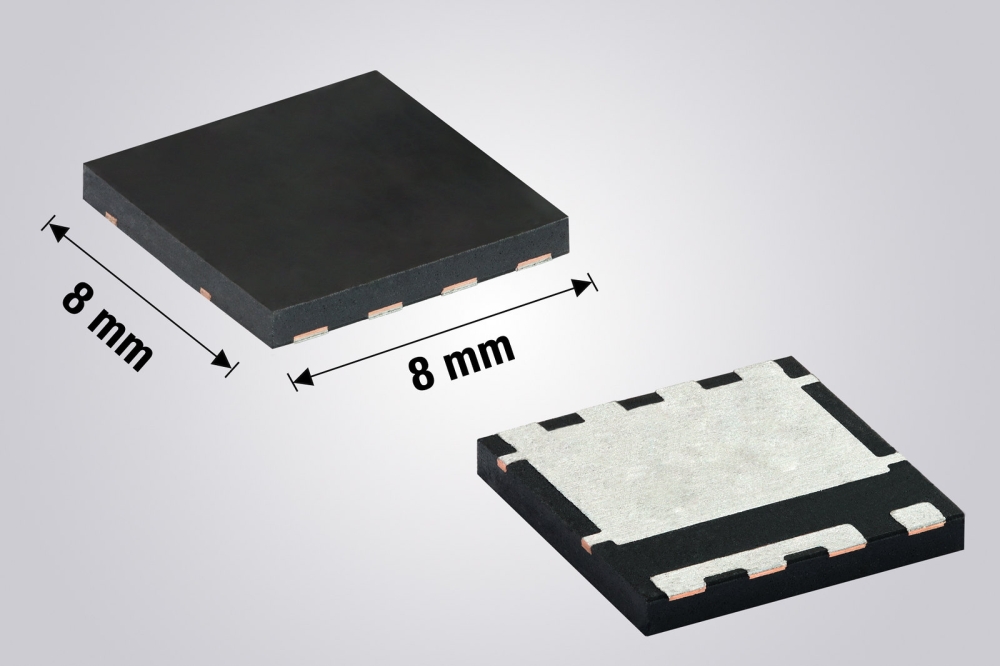

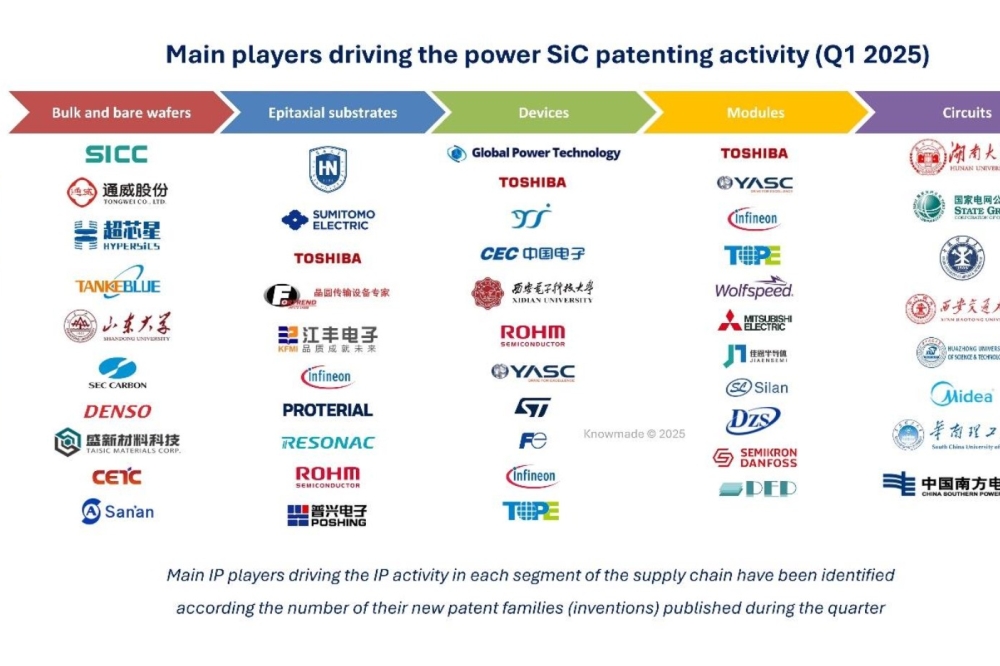

At CISM, Space Forge will begin to develop its terrestrial scale-up capability, focusing on radiation hard wide bandgap power electronics (such as SiC, GaN, Ga2O3), and microgravity growth-tool development.

CISM is part of the CSconnected compound semiconductor ecosystem in South Wales, and the UK's newest semiconductor research & development facility. With £55 million investment by the UK and Welsh Governments, it is designed for pilot-scale translation to manufacturing and start-up incubation.

To date, CISM has focused on clean energy, efficient power and microelectronics, semiconductors in healthcare, and over-the-horizon semiconductors. This new agreement marks an expansion into the development of semiconductor technology for space applications.

Paul Meredith, director of CISM said: “We are delighted to welcome Space Forge to CISM. Incubation of innovative SMEs and start-ups is part of our core mission. Space Forge will benefit from full access to our state-of-the-art fab but also be immersed in a vibrant community of semiconductor researchers, companies, innovators, and entrepreneurs. We hope the outstanding facilities and intellectual environment at CISM will help grow the Space Forge business faster and smarter to market.”

Alastair McGibbon, head of semiconductors at Space Forge commented on the facilities: “We are delighted to be the first incubation client at CISM, gaining access to their state-of-the-art clean room facilities and cutting-edge semiconductor tools.

“This partnership provides Space Forge with the critical infrastructure needed to advance our work in space-based manufacturing and terrestrial scale-up. With full access we’re now in an even stronger position to drive innovation - enabling us to continue to drive semiconductor manufacturing forward at pace.”