NVIDIA and Navitas to collaborate on 800V HVDC architecture

Navitas Semiconductor, maker of GaNFast GaN and GeneSiC SiC power semiconductors, has announced a collaboration with NVIDIA on the next-generation 800V HVDC architecture to support ‘Kyber’ rack-scale systems powering their GPUs, such as Rubin Ultra.

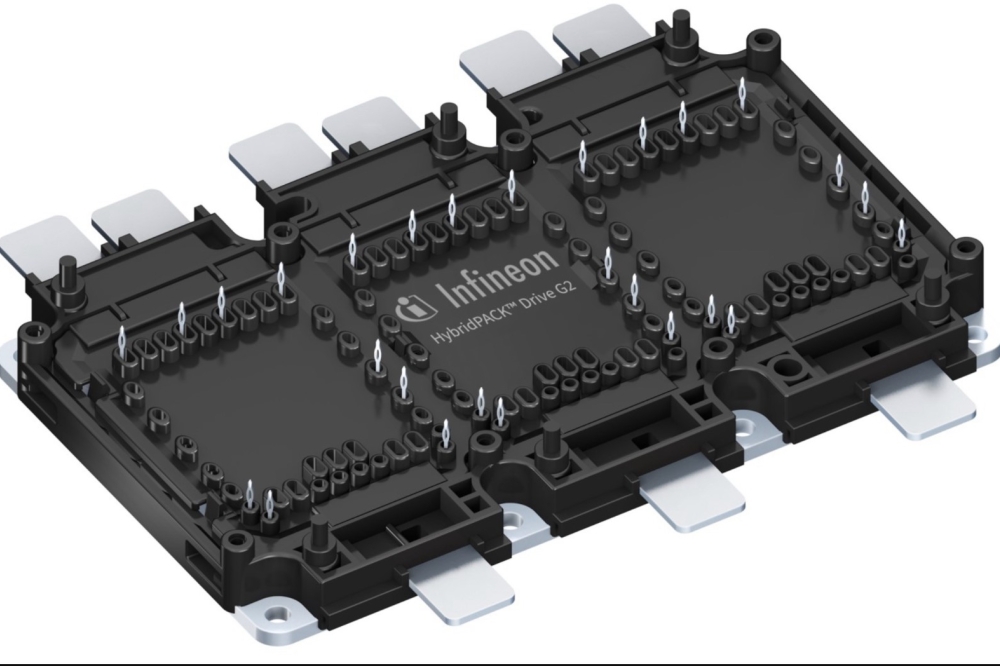

This follows an announcement from Infineon which will also be working with NVIDIA on HVDC around silicon, SiC and GaN technologies.

Gene Sheridan, CEO and co-founder of Navitas said: “Our latest innovations in high-power GaN and SiC technologies have seen world firsts and have created new inflections into markets such as AI data centres and electric vehicles. With our wide portfolio range, we can support NVIDIA’s 800V HVDC infrastructure, from grid to the GPU.” (Pictured above).

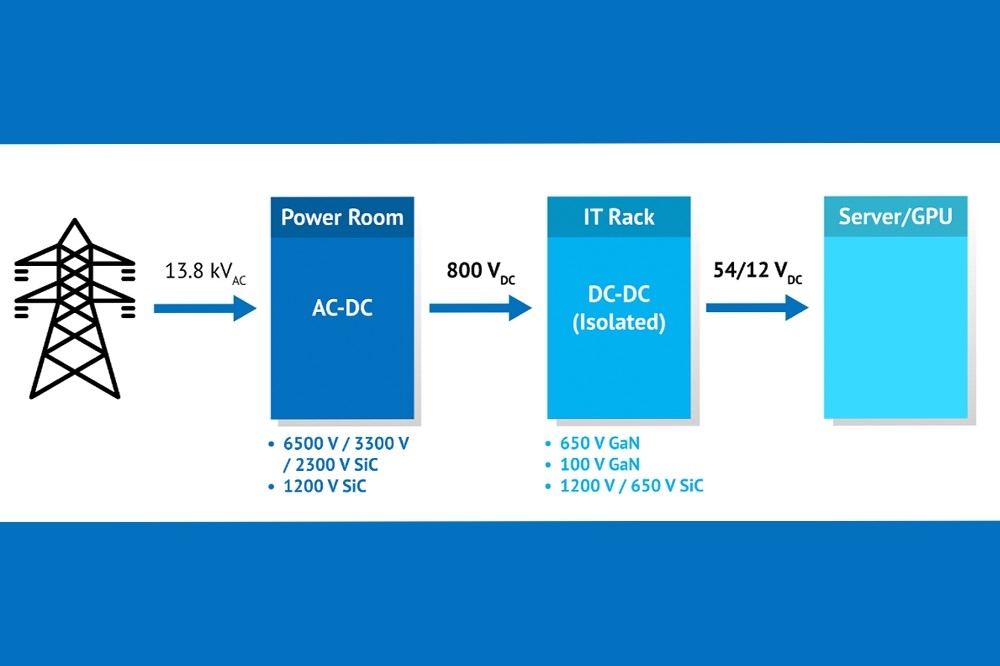

Targeted at 1 MW data centre IT racks and beyond, NVIDIA’s 800V HVDC architecture aims to improve end-to-end power efficiency up to 5 percent, reduce maintenance costs by 70 percent (due to fewer PSU failures), and lower cooling costs by directly connecting HVDC to the IT and compute racks.

Today’s data centre architecture uses traditional 54 V in-rack power distribution and is limited to a few hundred kilowatts (kW). Bulky copper busbars are required to transfer this low-voltage electricity from the rack-mounted power shelves to the compute trays. As power increases above 200 kW, this architecture runs into physical limits due to power density, copper requirements, and reduced system efficiency.

Modern AI data centres require gigawatts (GW) of power for the increasing demand for AI computation. Nvidia’s approach is to directly convert the 13.8 kV AC grid power to 800 V HVDC at the data centre perimeter using solid state transformers (SST) and industrial-grade rectifiers, eliminating several AC/DC and DC/DC conversion steps, maximising efficiency and reliability.

Due to the higher voltage level of 800 V HVDC, the thickness of copper wires can be reduced by up to 45 percent, due to I2R losses, where the same amount of power can be delivered with increased voltage and lower current. Using a traditional 54V DC system, over 200 kg of copper would be needed to power a 1MW rack, which is not sustainable for next-generation AI data centres with GW power demand.