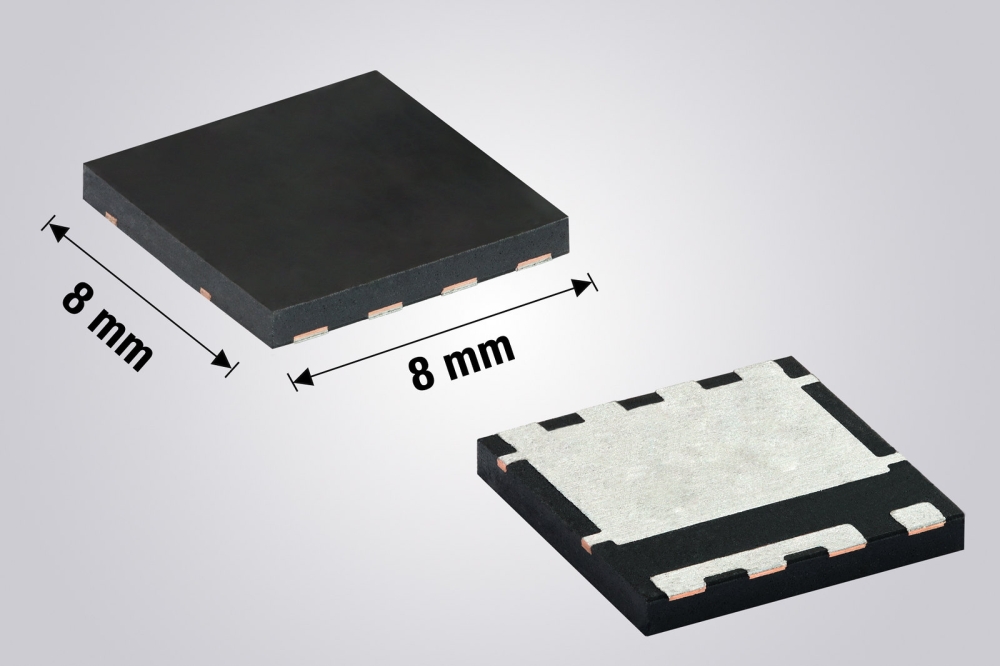

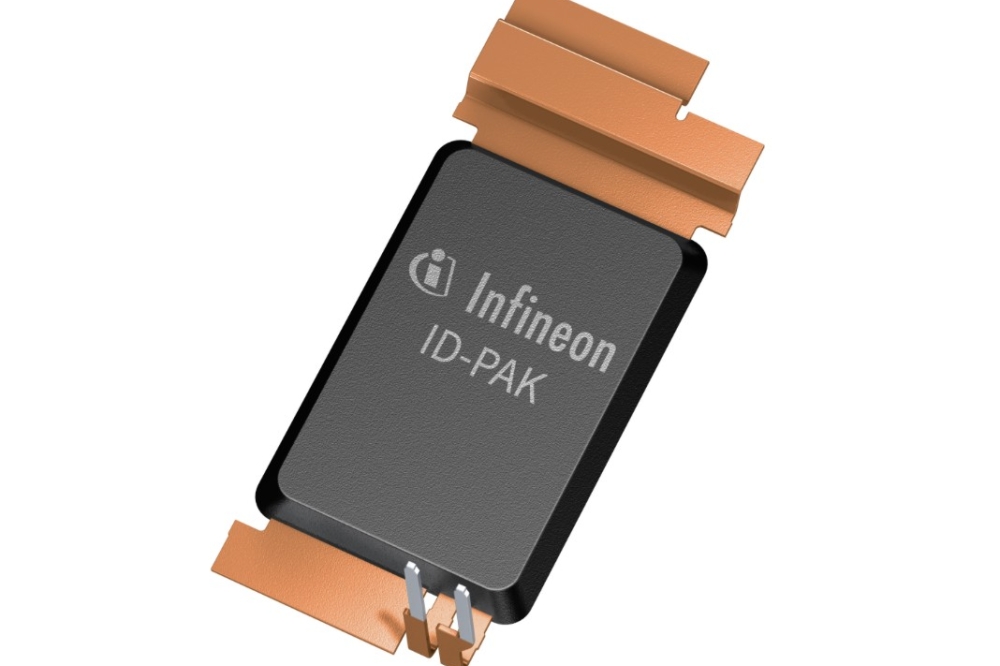

Introducing trench-based superjunction SiC

Infineon is introducing trench-based SiC superjunction (TSJ) technology, adding to its existing CoolSiC product offering spanning 400 V to 3.3 kV

“With the introduction of the TSJ concept, we are significantly expanding the technological capabilities of SiC,” said Peter Wawer, president of Infineon’s green industrial power division. “The combination of trench and superjunction technology enables higher efficiency and more compact designs – an important step for applications requiring the highest levels of performance and reliability.”

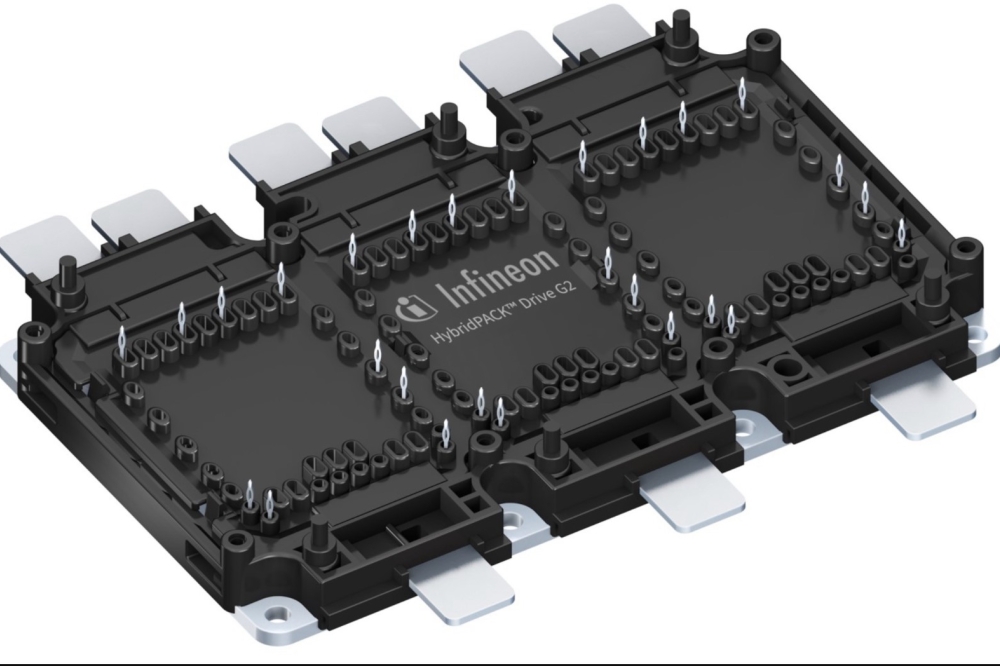

Infineon says it intends to gradually expanding its CoolSiC product portfolio with SiC TSJ technology. This expansion will encompass a diverse range of package types, including discretes, molded and frame-based modules, as well as bare dies. The extended portfolio will cater to a broad spectrum of applications, targeting both the automotive and industrial sectors.

The first products based on the new technology will be 1200 V in Infineon ID-PAK for automotive traction inverters and combine the advantages of trench technology and superjunction design, capitalising on Infineon’s more than 25 years of experience in SiC and silicon-based superjunction technology (CoolMOS).

This scalable package platform supports power levels of up to 800 kW, enabling a high degree of system flexibility. Key benefits of the technology include increased power density, achieved through an up to 40 percent improvement in R DS(on)*A, allowing for more compact designs within a given power class. Additionally, the 1200 V SiC trench-superjunction concept in ID-PAK enables up to 25 percent higher current capability in main inverters without compromising short-circuit capability.

This advancement also results in enhanced overall system performance, according to the company, delivering improved energy efficiency, reduced cooling requirements, and higher reliability for demanding automotive and industrial applications.

Moreover, the system benefits from reduced parallelisation requirements, which simplify the design process and lower overall system costs. With these innovations, the Infineon ID-PAK package equipped with SiC TSJ technology contributes to the development of more efficient and cost-effective traction inverter designs for automotive applications.

As an early customer, Hyundai Motor Company development teams will engage with Infineon's trench-superjunction technology, using its benefits to enhance their EV offerings. This partnership is expected to drive the development of more efficient and compact EV drivetrains.

Initial ID-PAK 1200 V samples are available for selected automotive drivetrain customers. The SiC TSJ-based ID-PAK 1200 V package is expected to be ready for volume production in 2027.