A step change in low-power circuit design

How the nPZero power-saving IC enables sensor system operation at the nanoamp level.

By Jan Frode Bergsø, Business Development Manager, Nanopower Semiconductor

A majority of IoT devices are powered by primary battery cells, also known as non-rechargeable batteries, but limited battery life and the need to replace discharged batteries create numerous problems:

• The cost to maintain a battery power supply, and to replace a discharged battery. This is particularly problematic in commercial and industrial environments, in which a large number of sensors might need regular battery replacement.

• The risk of suspension of system operation in the interval between the failure of a discharged battery, and its replacement with a fresh battery.

• The cost and environmental damage attributable to disposal of a battery at the end of its life.

In battery-powered IoT systems, which typically include a wireless connection to the internet, a smartphone, or to a central control system, the device’s RF system-on-chip (SoC) or microcontroller (MCU) is responsible for most of the energy consumption. Peripherals such as sensors also drain energy from the battery, but typically at a lower rate than the SoC does.

The power problem is inherent to a wireless SoC: the device needs a relatively high-performance, high-power compute system to handle the complex operation of a Bluetooth® Low Energy or similar radio protocol, as well as to perform control logic operations in response to significant sensor or user inputs. Yet in many applications, the full capability of this compute and communications circuitry is only deployed for a tiny fraction of the time. For more than, in some cases, 99% of the system’s operating time, the host device is greatly over-specified for the quiescent-state operations it performs.

MCU manufacturers have put a lot of research and development effort into trying to reduce their products’ power consumption in sleep mode, when the device is not performing communications or control operations. But there is a floor below which the power consumption of these big, sophisticated chips will not fall. And so embedded device manufacturers have previously had no choice but to build their power budget and to size their battery to cope with an SoC’s high power consumption even when their application is doing nothing apart from periodically monitoring sensor values.

Now Nanopower Semiconductor has developed a dedicated power-saving chip, a companion to the SoC, which reduces average system power consumption in typical endpoint wireless IoT devices by up to 90%.

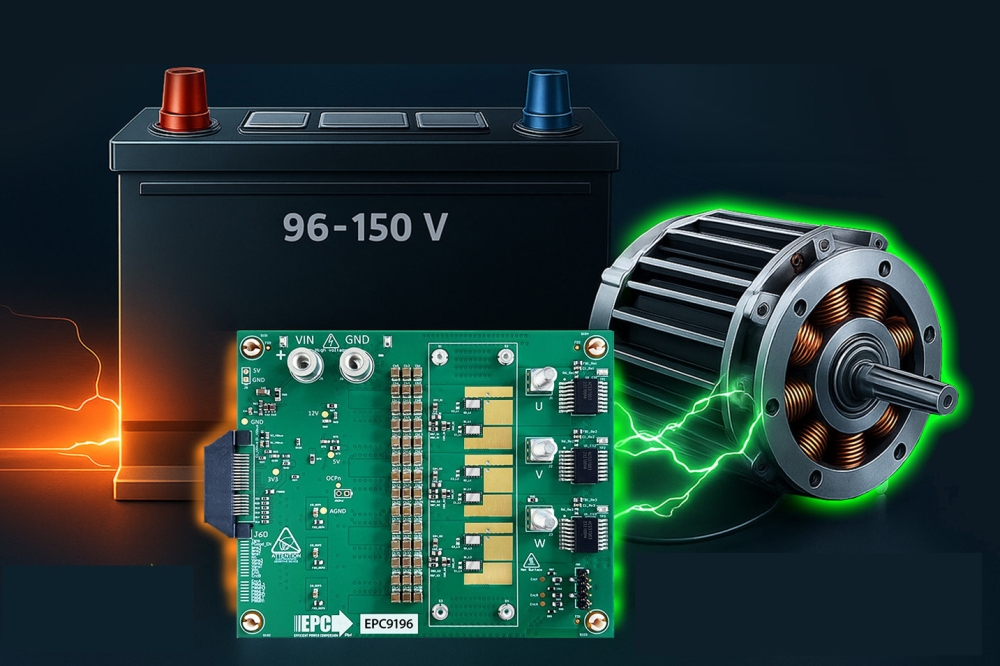

Figure 1. The nPZero IC operates as a companion chip to the SoC.

Finding a way to turn off the SoC

If the problem is the power consumed by the SoC when it is running, even in sleep mode, a solution might be found in switching off the SoC entirely. This is the theory behind the introduction of a new type of power-saving IC, a device which can perform the functions that the SoC performs when it is not active, but at a small fraction of the SoC’s power consumption.

This concept of this power-saving IC has been developed by European start-up company Nanopower Semiconductor, and has been implemented in its first-generation nPZero product.

The nPZero is compatible with most SoCs and sensors on the market (see Figure 1). In an IoT endpoint device comprised of one or more sensors and other peripherals, the nPZero takes over sensor monitoring and system control functions between radio transmissions or trigger events, enabling the SoC to shut down completely until a threshold event occurs that requires the nPZero to wake up the SoC and hand over control to it.

Thanks to the implementation of innovative sub-threshold mixed-signal technology developed by Nanopower, the nPZero draws less than 100nA when actively monitoring and controlling sensors. Nanopower has proved the potential of the nPZero to make system power savings in typical IoT device designs of between 50% and 90%. This results in:

• Greatly extended battery life, reducing replacement frequency and cost

• The option to reduce battery size, allowing for more compact device designs

• The potential for battery-free operation. The Nanopower power-saving technology can enable the addition of a harvested energy source, eliminating the risk of battery power failure, or even enable a system to run on harvested energy

alone.

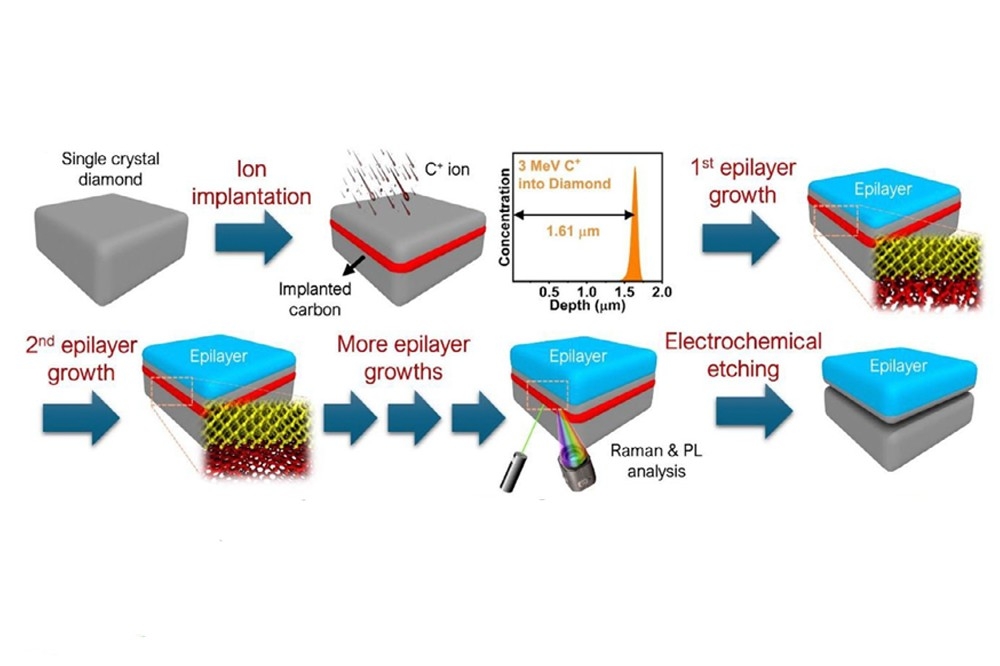

Figure 2. The zero-code tool for configuring the nPZero’s operation features an intuitive GUI

How the nPZero minimizes power consumption in the quiescent state

The typical use case for the nPZero is in IoT endpoints which monitor system parameters, such as temperature or motion, and which only communicate when a notifiable event occurs (such as the temperature crossing a pre-set threshold value, or excessive vibration). The nPZero performs system monitoring with the host SoC switched off, and wakes up the SoC only when a notifiable sensor value has to be transmitted. The nPZero might typically also wake up the SoC at a regular interval to send a system update.

In system monitoring mode, the nPZero can operate on an interrupt basis: here, the sensor is always on, and its state machine interrupts the nPZero when an event needs to be triggered.

Alternatively, the nPZero can operate in I2C or SPI mode: here, the nPZero polls sensors on a pre-set schedule. This means that the sensors can be switched off between polling events, saving even more power.

Nanopower provides a zero-code nPZ Configurator tool for configuring sensors in the system, applying polling schedules, and setting the parameters for triggering events (see Figure 2). The nPZ Configurator tool automatically generates the firmware code needed for the host MCU to configure the nPZero. The code can be inspected and manually edited in the tool if needed.

Additionally, the tool can analyse the state of power switches and serial interfaces in a running system, allowing the user to evaluate the efficiency of a given implementation, and tune the configuration of the nPZero device to their requirements.

Hardware implementation is also straightforward: the nPZero requires only a few external passive components, and an optional crystal for more accurate time keeping.

Test system demonstrates power-saving potential of nPZero

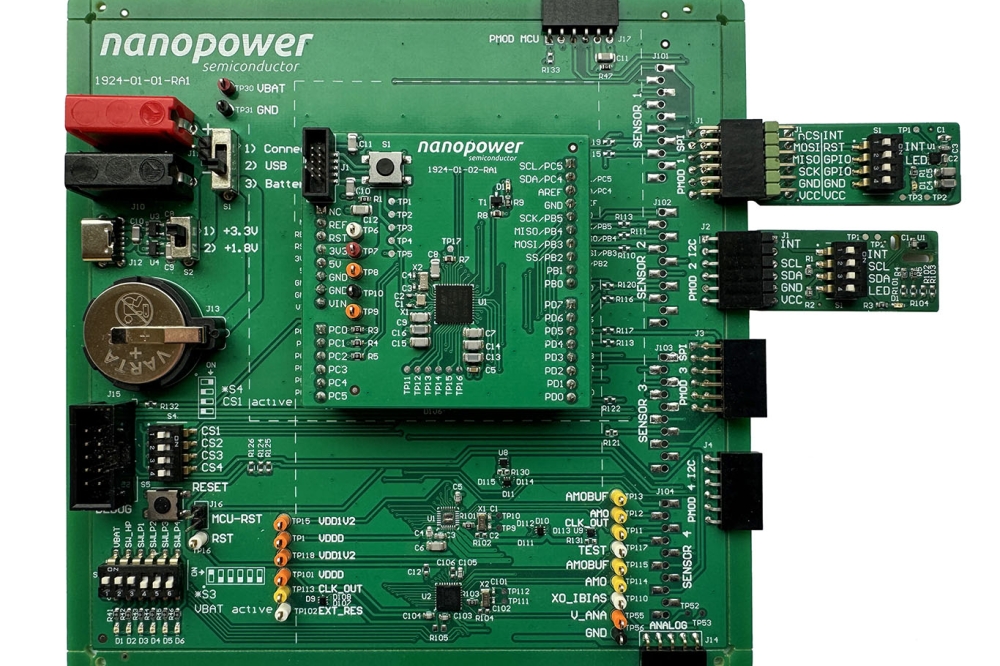

The potential for power-saving in endpoint IoT devices can be seen in a comparison between a conventional design implementation and a demonstration system based on the nPZero IC. The test system is based on the nPZero Evaluation Board (EVB). This is a modular system which makes it easy to add sensors to the nPZero baseboard via PMOD headers, and to add an SoC daughtercard via an Arduino Uno-compatible interface.

The demonstration design uses the ams OSRAM AS6212 temperature sensor and STMicroelectronics LIS2DW12 accelerometer boards that are shipped by Nanopower with the EVB. The SoC is an nRF52840 Bluetooth Low Energy microcontroller from Nordic Semiconductor (see Figure 3).

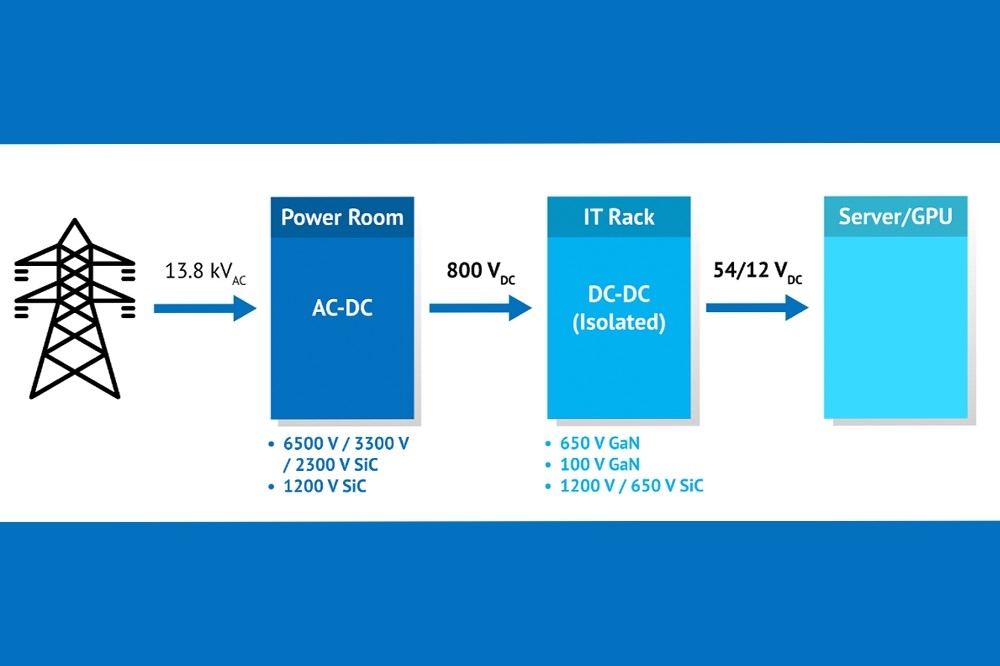

Figure 3. In the nPZero EVB, the nPZero manages sensors’ operation with

the SoC host switched off, and only wakes up the SoC when a sensor’s

threshold value is crossed, or for scheduled data uploads.

Such a system might typically be used in applications such as monitoring the condition of goods in transit, or for cold-chain data logging. The test system is set up to provide frequent measurements. The temperature sensor is read every 4s and the accelerometer every 0.625s. The nPZero IC is set to wake the host if a movement is detected or the temperature is outside the range 18°C to 28°C. Regardless of sensor measurements, the host also wakes up every 5 minutes to send the most recent sensor readings via Bluetooth link.

The test compared total energy consumption of the EVB system first without the nPZero – that is, with the nRF52840 SoC controlling the sensors’ operation directly – and then with the nPZero, allowing the SoC to be switched off between radio transmissions.

With the nRF52840 controlling the sensors via I2C interfaces, and the nPZero disabled, average current over an hour’s operation was 395.4µA.

After enabling the nPZero to control the system via I2C, allowing the nRF52840 to be switched off between transmissions and the sensors to be duty-cycled, average current falls to 49.6µA – a reduction of 87%, while providing exactly the same functionality and performance.

Figure 4. The nPZero EVB enables users to add their choice of PMOD sensor board and SoC daughtercard.

How to evaluate the nPZero’s operation

Designers of endpoint IoT devices can evaluate this performance themselves with the nPZero EVB and their choice of PMOD sensor boards and SoC daughtercards (see Figure 4). The nPZero Configurator tool is available free for users of the EVB.

OEMs can also emulate a demonstration design developed by Nanopower which shows how the nPZero can be used to substitute harvested energy for a battery power supply. Developed jointly with TDK, this system features the nPZero power saving IC continuously controlling environmental sensors including the TDK CH201 time-of-flight sensor. The battery-free system is powered by TDK CeraCharge solid-state batteries energized by Epishine indoor photovoltaic cells.

Naturally, power is not the only aspect of a system design that an OEM cares about: decisions about the use of the nPZero IC are also affected by the question of system cost and size. Here as well, the nPZero has a powerful case to make: as Figure 3 shows, the nPZero includes an internal low-power oscillator and power switches, enabling external components implementing these functions to be eliminated from the bill-of-materials.

In addition, the power savings produced by the nPZero can enable the OEM to reduce the size of the battery and the system enclosure.

So the nPZero offers considerable advantages to designers of wireless endpoint IoT devices, and thanks to the availability of the nPZero EVB, these advantages can readily be evaluated in the user’s application.