US team develop new thermal interface material

A team led by scientists and engineers at The University of Texas at Austin have created a new thermal interface material that could organically remove heat from high-powered electronic devices, reducing or even eliminating the need for extensive cooling.

The new material, made from a mix of liquid metal and aluminium nitride, is said to be much better at conducting heat than current commercial materials, making it optimal for cooling.

“The power consumption of cooling infrastructure for energy-intensive data centres and other large electronic systems is skyrocketing,” said Guihua Yu, professor in the Cockrell School of Engineering’s Walker Department of Mechanical Engineering and Texas Materials Institute. “That trend isn’t dissipating anytime soon, so it’s critical to develop new ways, like the material we’ve created, for efficient and sustainable cooling of devices operating at kilowatt levels and even higher power.”

Cooling accounts for about 40 percent of data centre energy usage, or 8 terawatt-hours annually. The researchers estimate their technology could shave 13 percent off that cooling requirement — or 5 percent off overall data centre energy usage — a significant savings if applied across the industry. The heat dissipation capabilities also allow for significant growth in processing power.

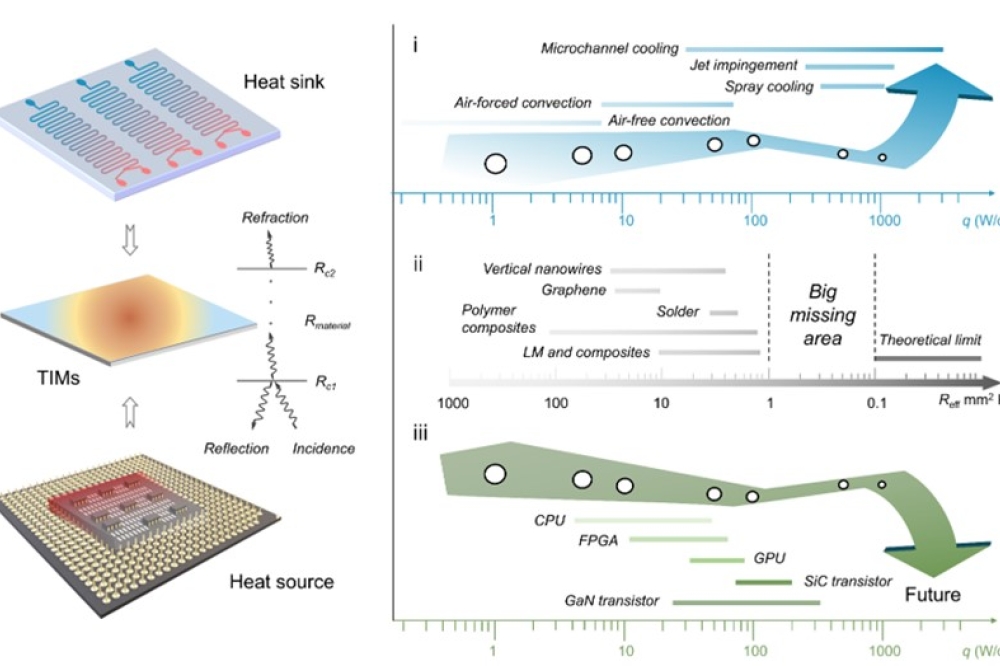

The new discovery published in Nature Nanotechnology is part of a larger effort to realise the potential of thermal interface materials.

Currently, a gap exists between how much cooling these materials should theoretically be able to achieve and what they’ve done in real-world tests.

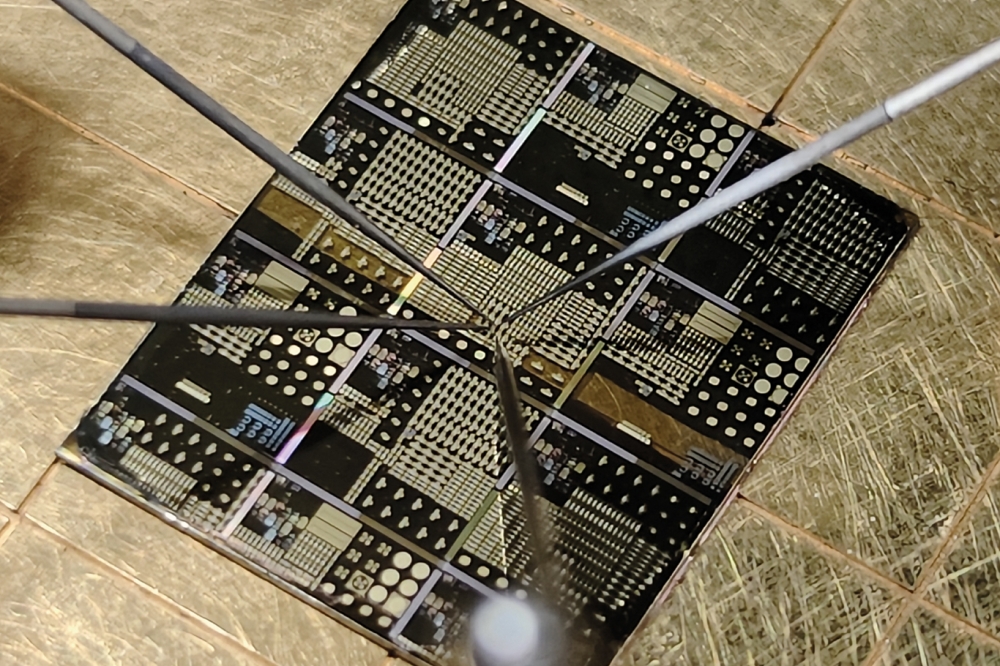

The new materials in this project were able to bridge that gap. This material can remove 2,760 watts of heat from a small area of 16 square centimeters. It can cut the energy needed for the cooling pump, a significant piece of the overall electronics cooling puzzle, by 65 percent.

“This breakthrough brings us closer to achieving the ideal performance predicted by theory, enabling more sustainable cooling solutions for high-power electronics,” said Kai Wu, lead author in Yu’s lab. “Our material can enable sustainable cooling in energy-intensive applications, from data centres to aerospace, paving the way for more efficient and eco-friendly technologies.”

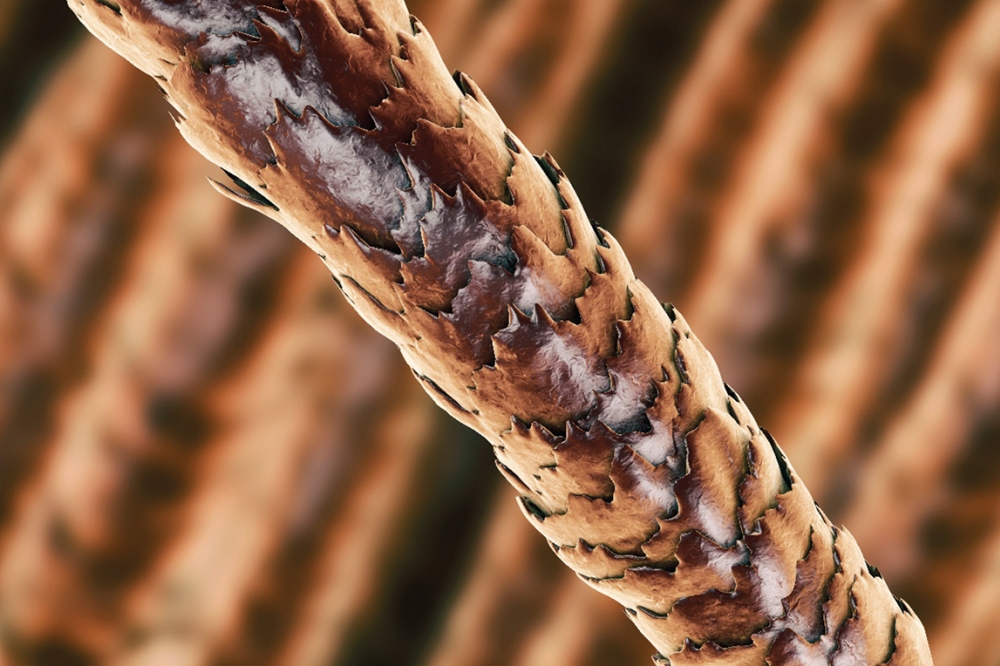

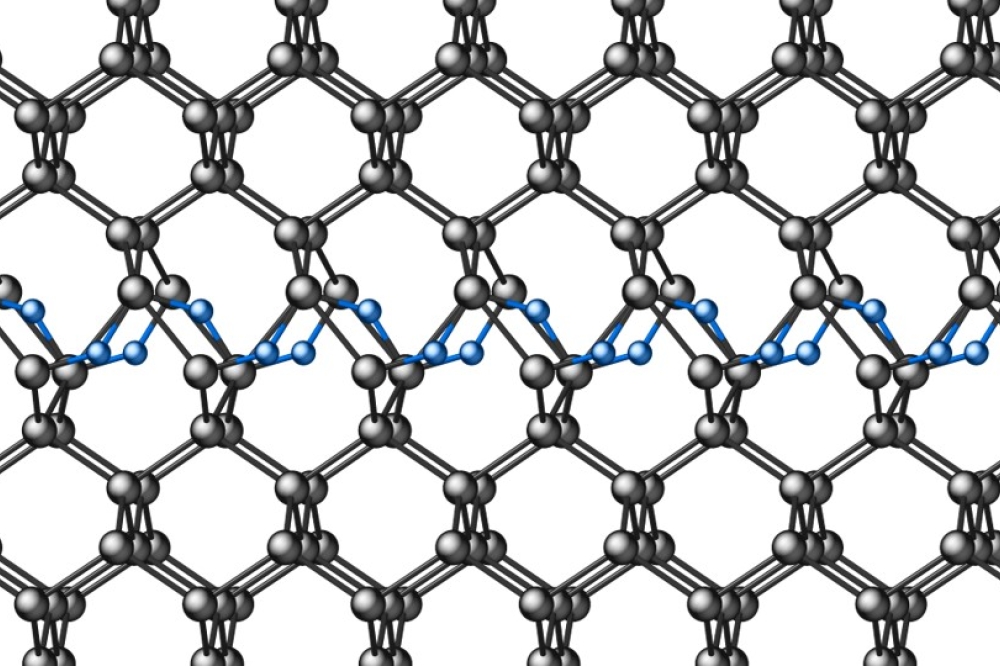

The researchers created the new cooling material using a process called mechanochemistry. This process helps the liquid metal and aluminium nitride mix in a controlled way to create gradient interfaces, making it easier for heat to move through them.

The researchers have tested their materials on small lab-scale devices. The team is in the process of scaling up material synthesis and preparing samples to test with partners in data centres.