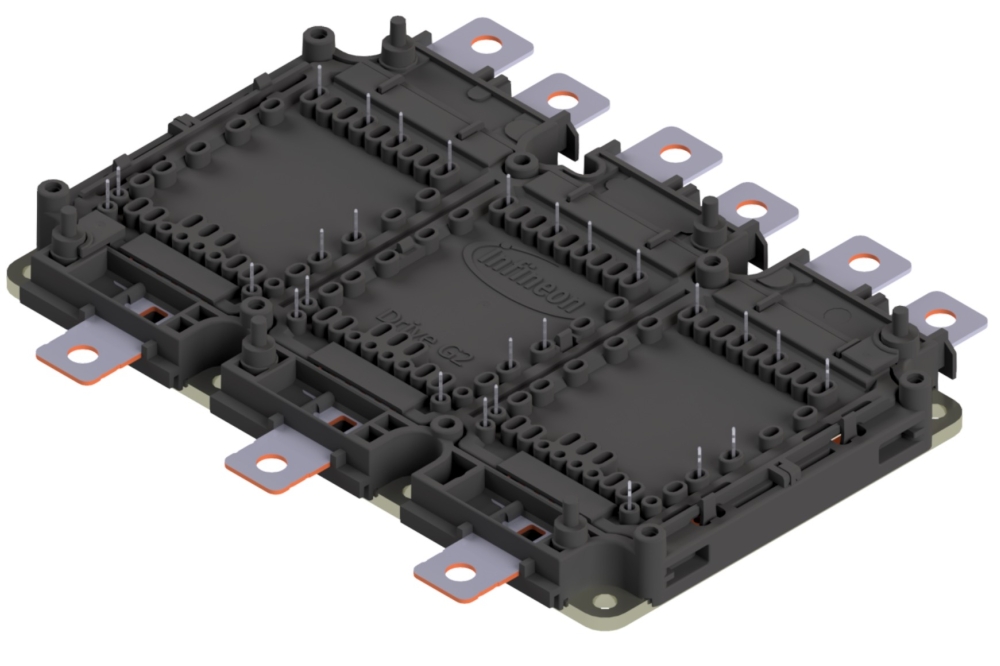

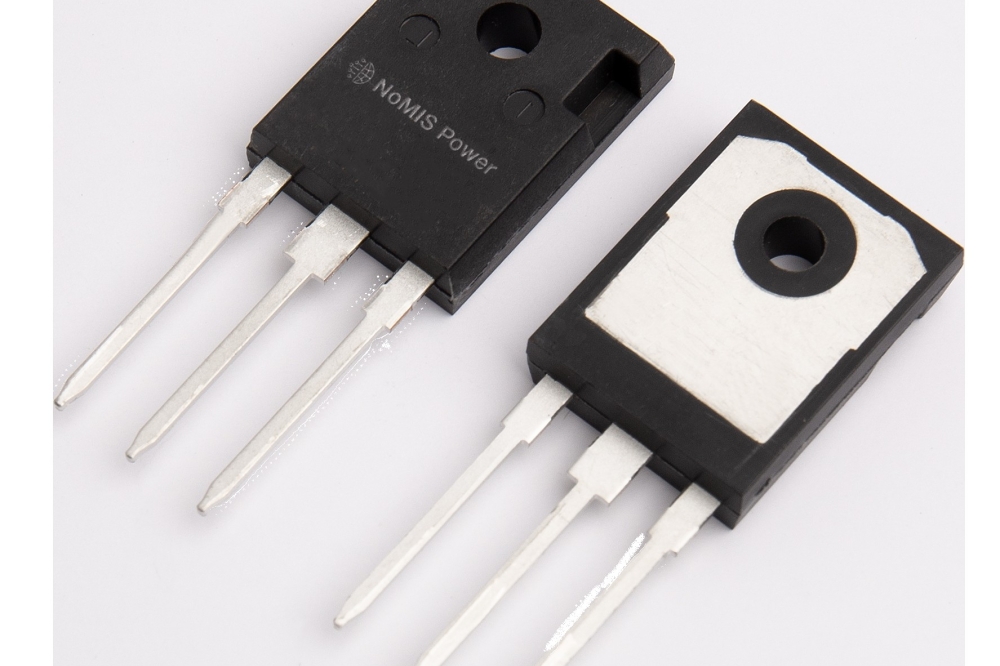

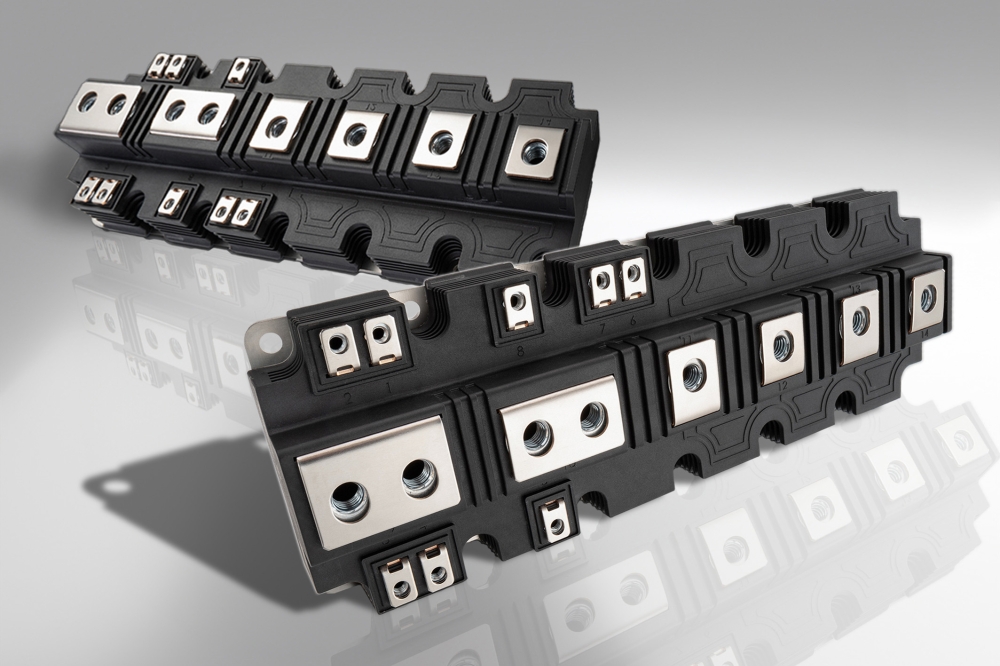

Semikron Danfoss uses new BASF material for IGBTs

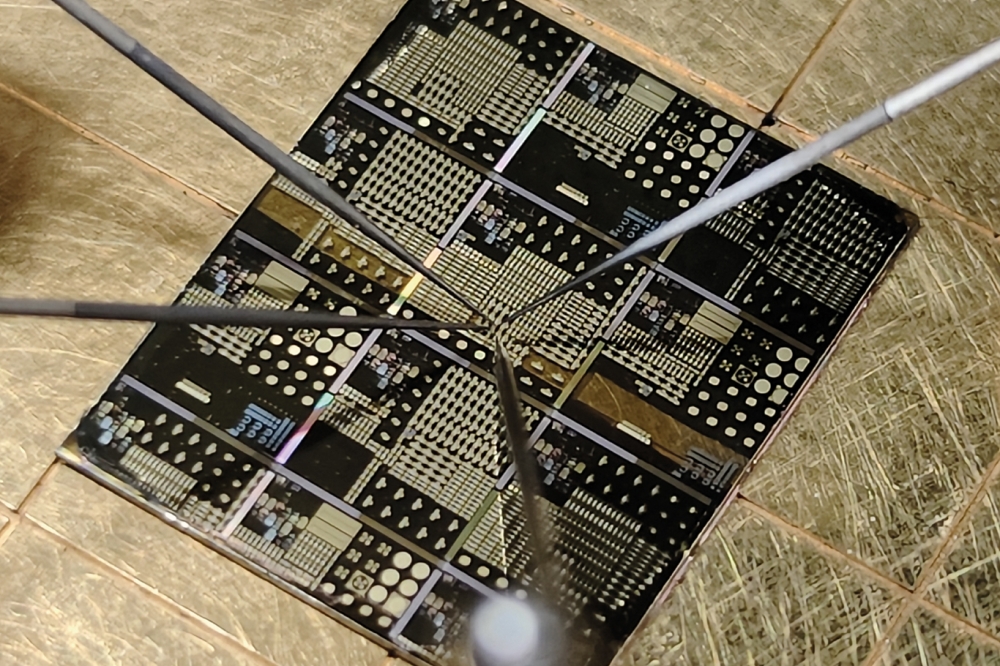

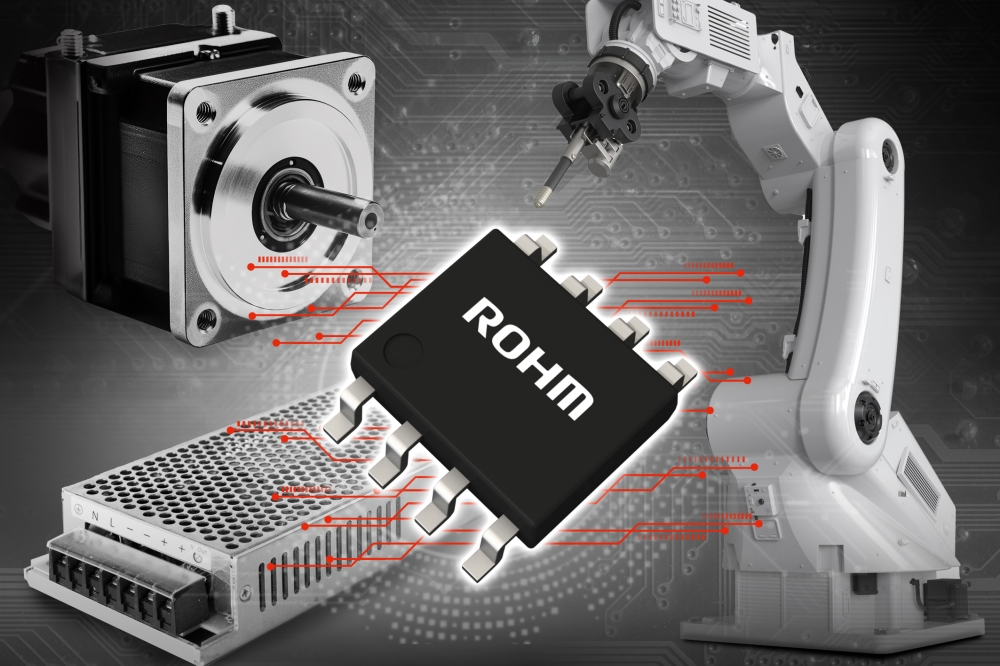

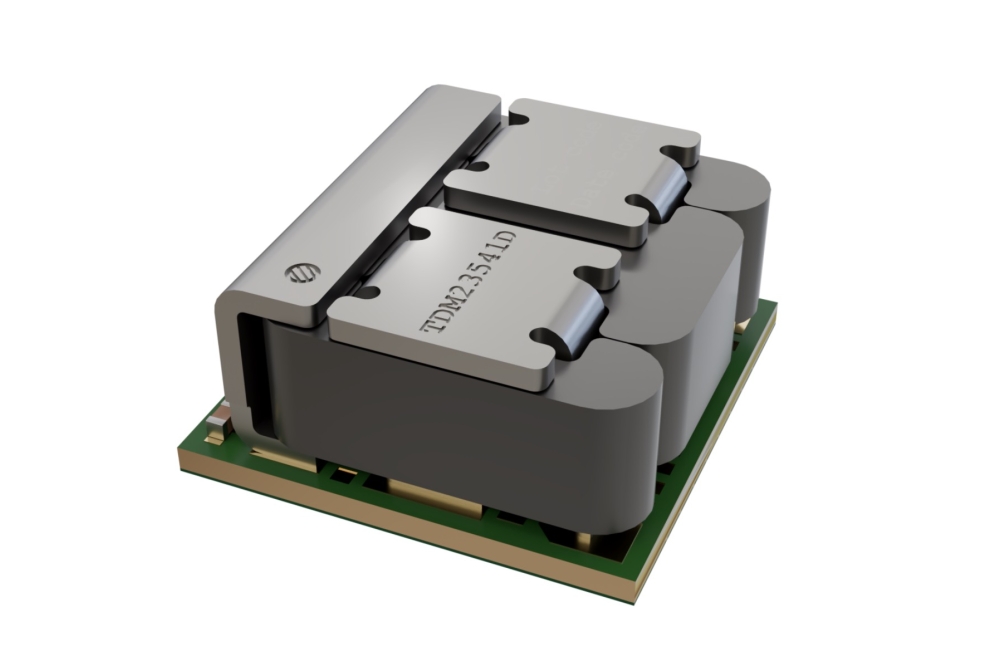

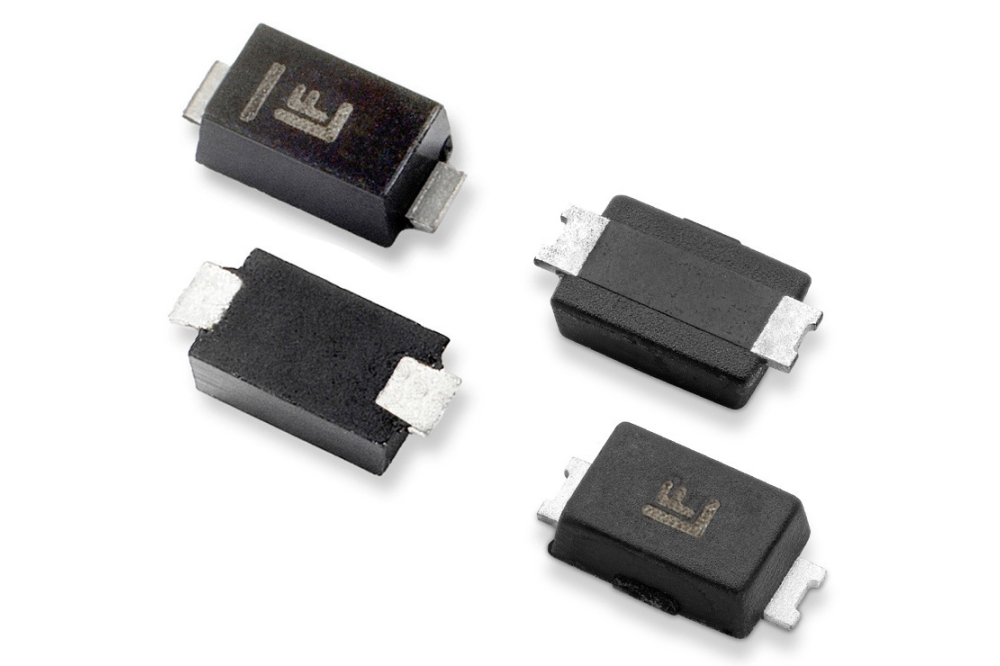

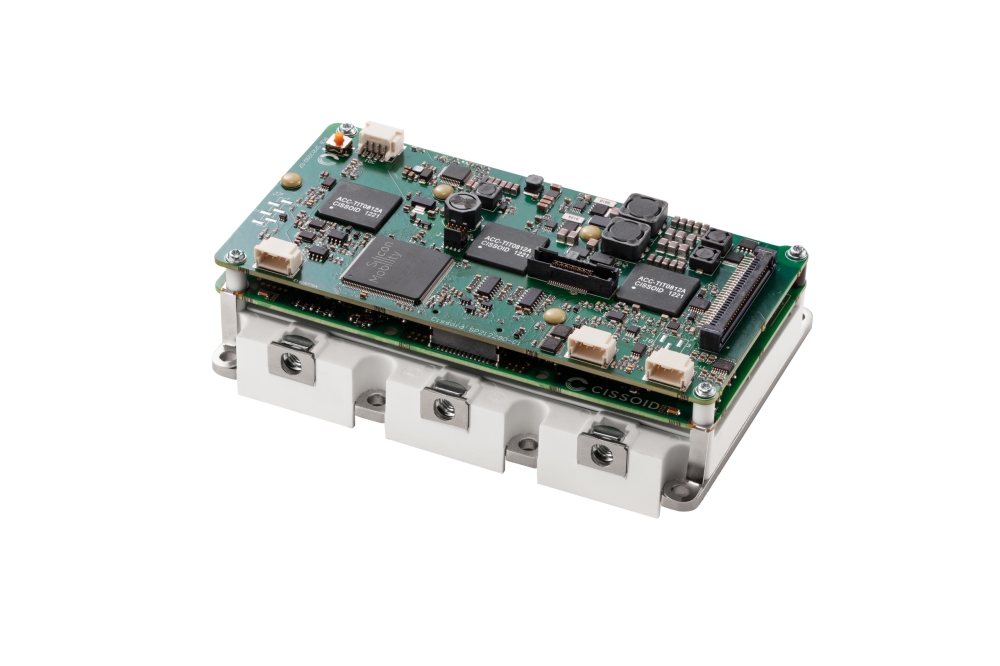

Power electronics firm Semikron Danfoss is using a new polyphthalamide (PPA) material from BASF for housing its Semitrans 10 IGBT which is designed for inverters of photovoltaic and wind energy systems.

BASF developed its Ultramid Advanced N3U41 G6 PPA to address the growing demand for high-performance, reliable electronic components for electric vehicles, high-speed trains, smart manufacturing and the generation of renewable energy.

Jörn Grossmann from research and predevelopment at Semikron Danfoss said: “IGBTs must operate at higher temperatures while maintaining long-term stability and performance. The Semitrans 10 has set a new benchmark for performance and efficiency benefiting from the unique properties of BASF’s PPA. We chose this material because of its extraordinary electrical isolation even in harsh environments and because of its excellent robustness against short-term temperature peaks in the assembly process.”

The combination of high-performance material and smart design allows for faster switching speeds, lower conduction losses, and improved thermal management, thus addressing key needs in power electronics.

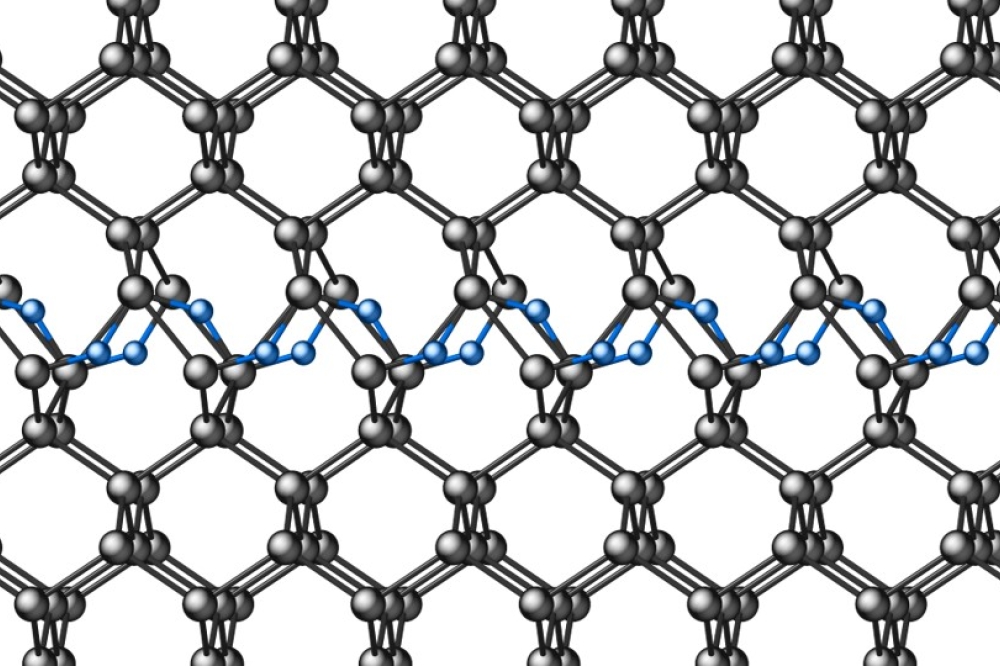

In today’s IGBTs, BASF’s Ultradur (PBT: polybutylene terephthalate) is widely used. The new PPA is designed to meet the stringent requirements of next-generation IGBTs for rapidly evolving power electronics. They demand materials that can withstand higher temperatures, provide sustained electrical insulation, and maintain dimensional stability under challenging environmental conditions like humidity, dust and dirt.

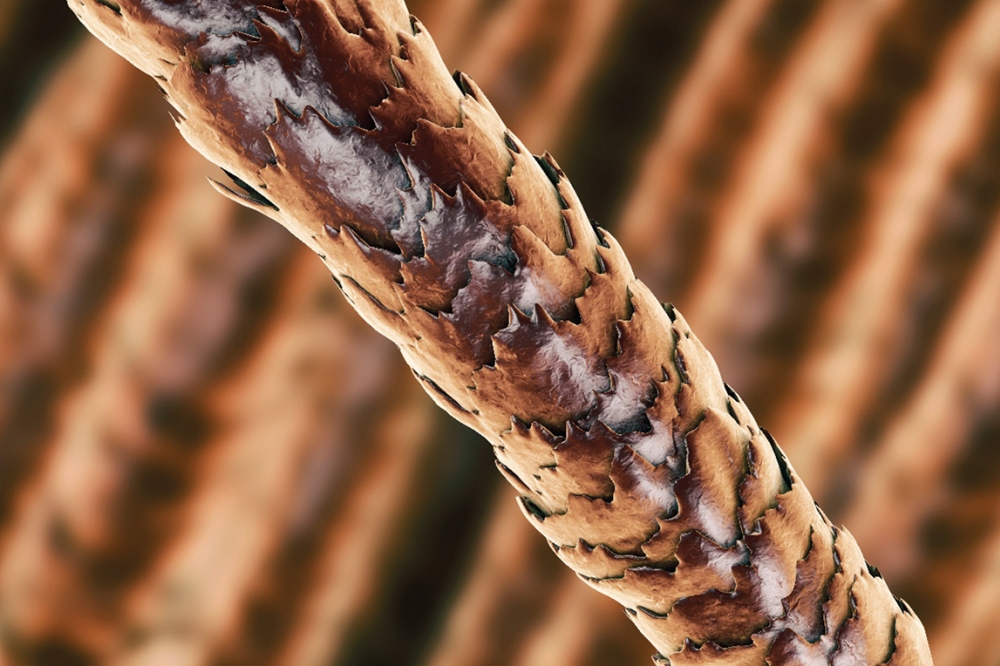

The laser-sensitive Ultramid Advanced N3U41G6 with non-halogenated flame retardant is said to combine high thermal stability with low water uptake and excellent electrical properties. It is characterised by a high CTI (Comparative Tracking Index) of 600 (acc. to IEC 60112): This supports miniaturisation of IGBTs by lower creepage and better insulation than materials so far used for power switches. The UL-certified grade shows an excellent electrical RTI (Relative Temperature Index) value of 150°C.

“BASF's PPA compound is globally available and ready for sampling”, says Jochen Seubert, senior application expert for power electronics at BASF. “Backed by our customer-focused technical support in part development, we expect this innovative material to significantly contribute to the advancement of power electronics, supporting the global transition to renewable energies.”

For manufacturing of IGBTs, the BASF PPA is compatible with potting materials used to assemble the semiconductors with metal pins and clamps after injection molding.