NREL to design SiC inverter for US combat vehicles

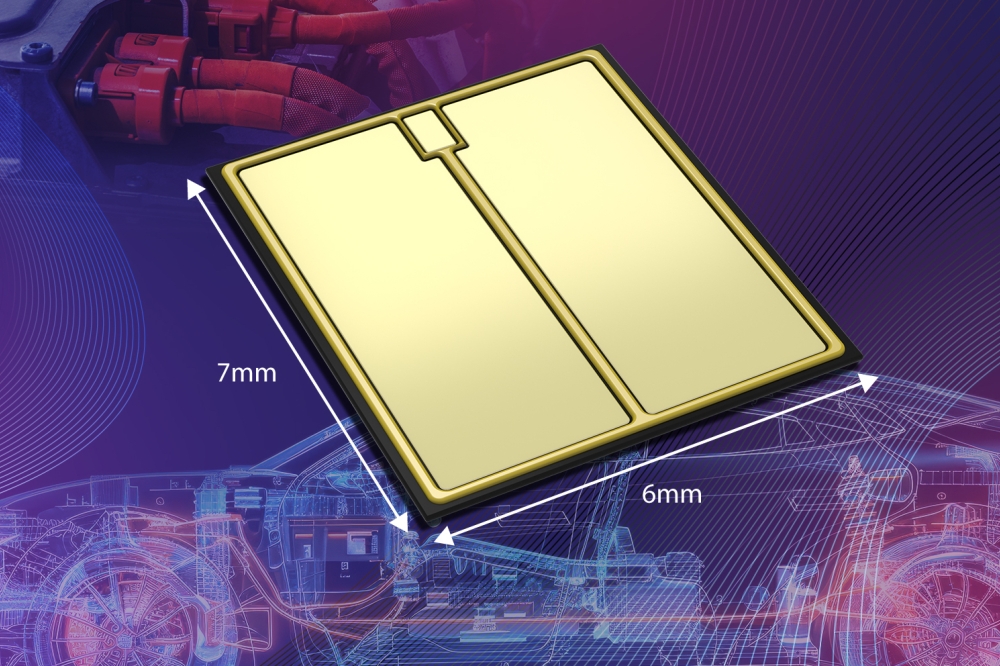

The US National Renewable Energy Laboratory (NREL) will be redesigning the traction inverter used in US ground combat vehicles, with a SiC -based propulsion system that will double vehicle range in a footprint four times smaller than its predecessors.

The new inverter, called PICHOT, is expected to save 53 percent of fuel compared to existing technologies, meaning vehicles will be able to stay in the field for nearly twice as long before needing to refuel.

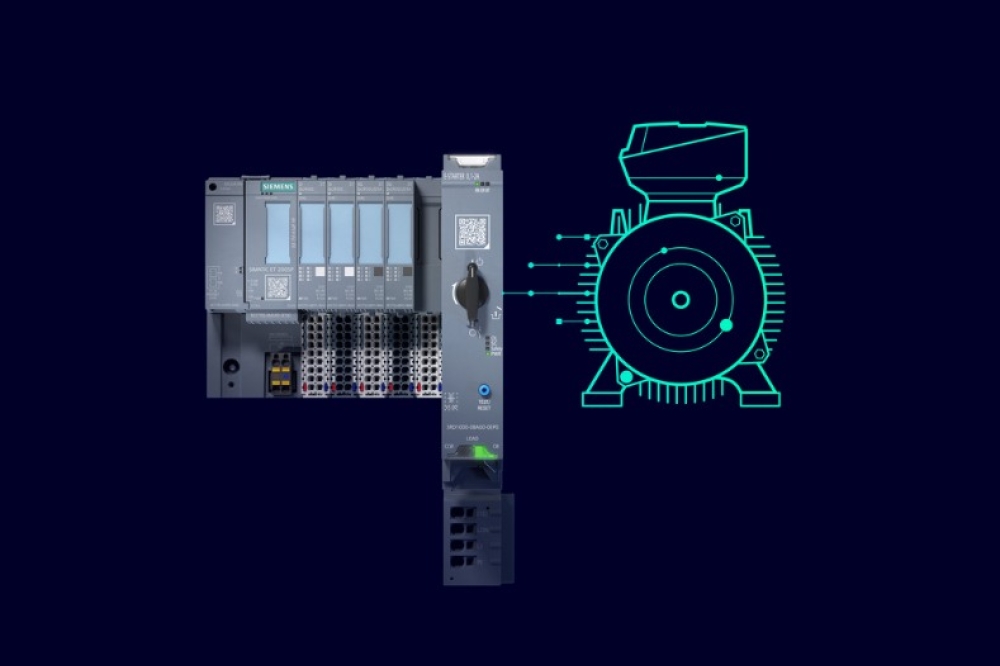

To create PICHOT, NREL says it is reimagining nearly every aspect of conventional power inverters.

Because traction inverters are typically installed next to other heat-generating elements in a combat vehicle, they need to be able to withstand high operating as well as ambient temperatures. This usually requires them to be packed with bulky cooling technologies, like cold plates or coolant reservoirs.

PICHOT will require none of these heavy cooling solutions, according to NREL. Instead, it will link to the existing engine coolant system, eliminating the need for additional coolant loops. In turn, unlike conventional silicon-based inverter systems—which become essentially powerless when exposed to operating environments over 70°C—PICHOT will be able to function at full power in environments of 105°C.

PICHOT will be capable of the same 200-kilowatt output as its predecessor, Zeus, but at a fourth of the size—small enough to fit in a shoebox. And to reduce electrical wiring , PICHOT’s main communication will be a tailored wireless system featuring remote control and monitoring. It will even come equipped with a 'smart' feature that allows it to monitor its own state of health: in other words, to predict component failure before it occurs.

Combined with silent performance thanks to the hybrid-electric engine and electromagnetic interference shielding, Army ground combat vehicles are poised to become safer, longer-range, and higher-performing than ever before, says NREL.

NREL predicts that PICHOT will take three years to design, fabricate, and evaluate. In the first year, NREL researchers will build a computer-generated model of the inverter and simulate its operations in the real world, ensuring that it will operate as planned. Then, they will build it using the laboratory’s end-to-end prototype fabrication pipeline and demonstrate its effectiveness versus other combatants’ standard vehicles.

Finally, the blueprints will become available to manufacturers at a forthcoming industry day. The final design will be manufactured at scale, with potential to be leveraged in multiple kinds of US Army ground combat vehicles.

The three-year, $6 million project has been funded by the Operational Energy Capability Improvement Fund (OECIF), which guides energy innovations for the United States Department of Defense. It will be led by the United States Army Combat Capabilities Development Command, known as DEVCOM, with researchers from both NREL and the Army Research Laboratory (ARL) providing technical expertise.