Hydro Leduc uses CISSOID’s SiC module

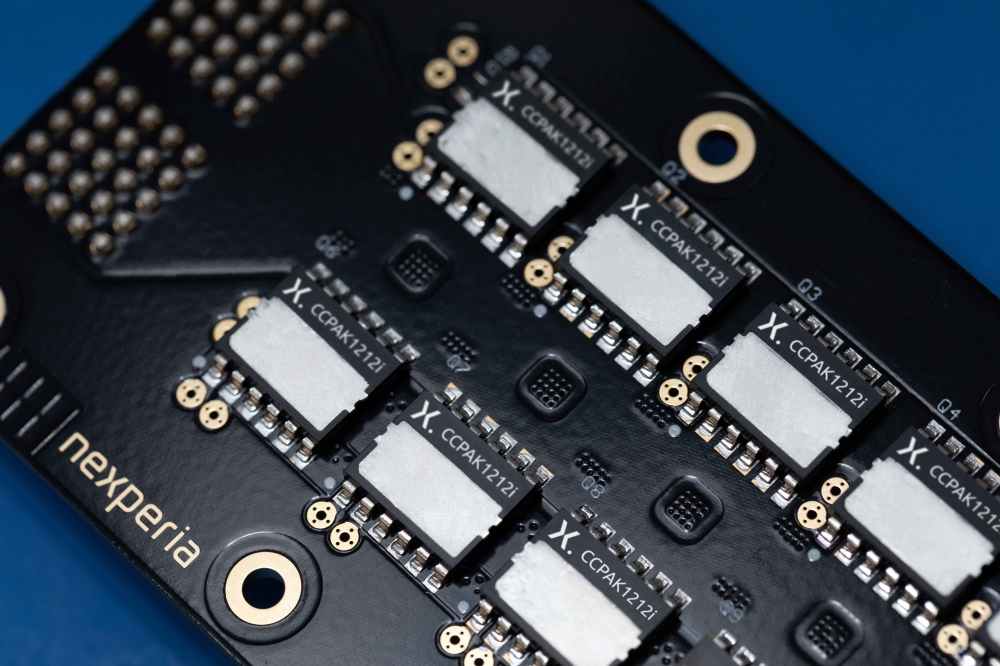

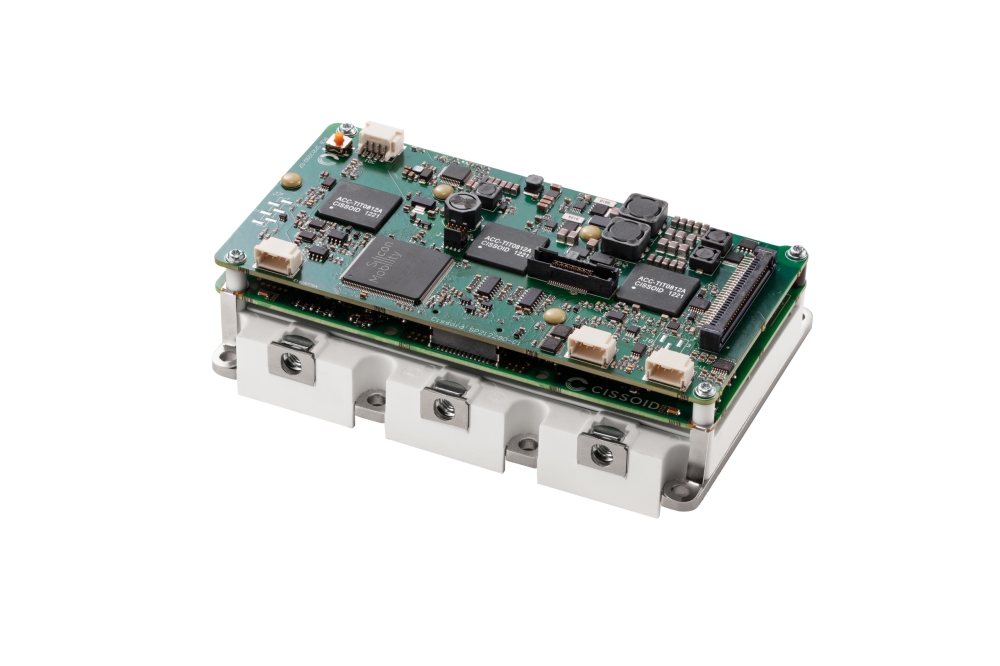

CISSOID, a power semiconductor solutions company, has announced that its SiC Inverter Control Module (ICM) has been adopted by Hydro Leduc, a manufacturer of hydraulic components, for its new electric Power Take-Off (ePTO), used in the electrification of trucks and other off-road vehicles.

Hydro Leduc’s new ePTO solution offers an optimised hydraulic supply to high power tools in e-trucks and other off-road vehicles that remain driven by hydraulic actuators. The company says the ePTO represents a significant advancement in electric and hydraulic transmissions with its ME230, a 76 kW brushless electric motor designed to be paired with an inverter for applications up to 650Vdc.

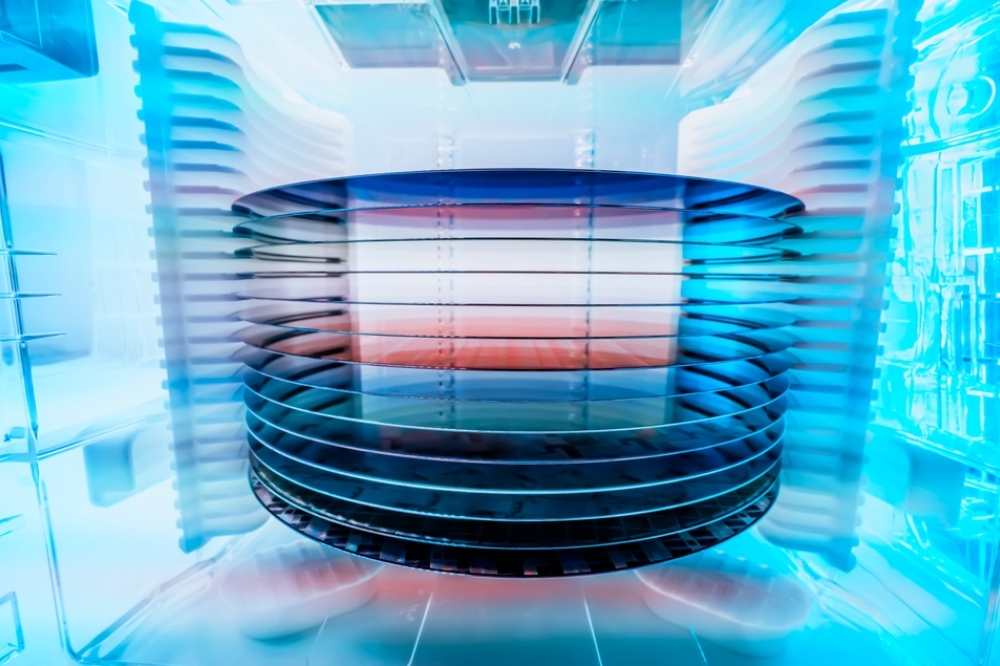

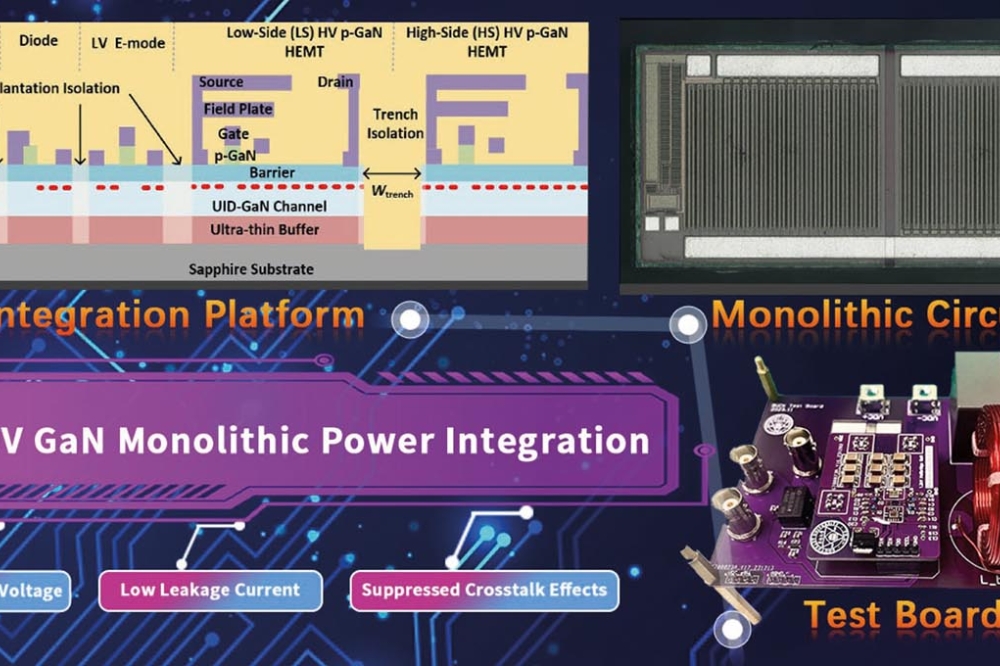

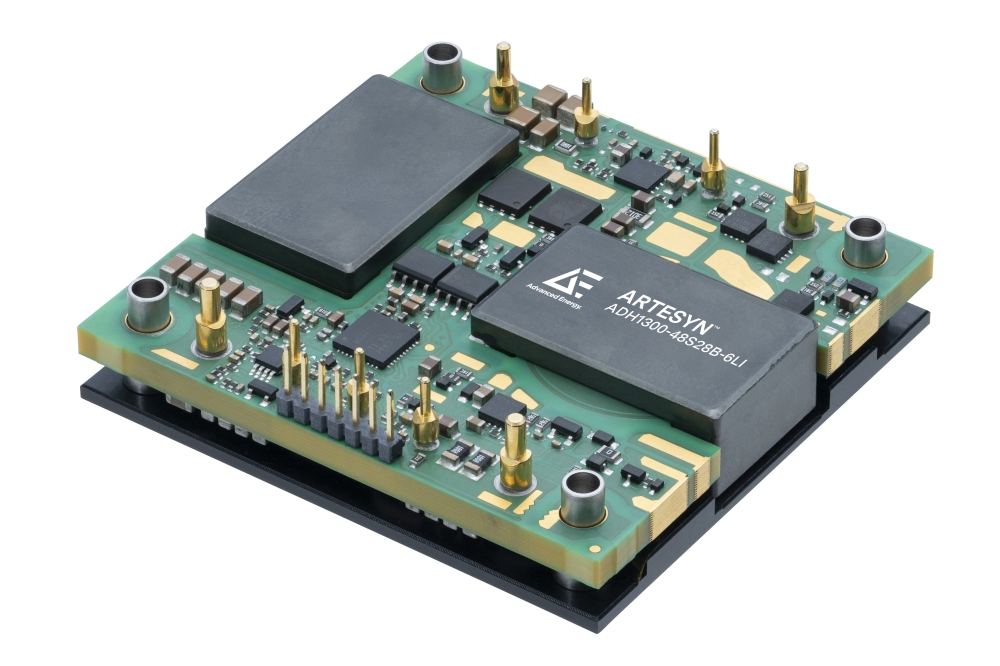

CISSOID’s ICM integrates a 3-Phase 1200V/340A-550A SiC power module, enabling efficient power conversion, a gate driver board designed for safe driving of the fast-switching SiC transistors, and a control board embedding a powerful real-time microprocessor. This hardware platform has been delivered together with the OLEA APP INVERTER software optimised for the efficient and safe control of electric motors.

Olivier Savinois, managing director at EL MOTION (the sister company of Hydro Leduc, specialised in the design and manufacturing of electrical components and motors), said: “We have been very pleased to work with CISSOID on the development of our new ePTO inverter. Not only did their SiC Inverter Control Module completely match our needs, we also enjoyed outstanding support from their team. Especially due to the on-site calibration of our inverter and motor, during the design and validation phases. CISSOID’s modular inverter platform ties perfectly with our scalable ePTO solution.”

Emmanuel Poli, VP sales at CISSOID, said: "It was really exciting to work with the Hydro Leduc team, who rapidly understood how powerful it would be to leverage our ICM to accelerate the design of their inverter. We were impressed by the speed and agility of Hydro Leduc’s engineers in integrating our hardware and software solution into their motor drive."