Celebrating a century of innovation in power electronics: Schneider Electric

Schneider Electric, the industrial technology leader of energy management and automation, have been at the forefront of innovation for over 100 years. PEW talks to Ionut Farcas, SVP, Europe Hub, Global Power Products at Schneider Electric about how the TeSys motor control solutions, including the upcoming TeSys Tera and TeSys Deca Advance, has been able to meet modern challenges such as sustainability and efficiency.

PEW: Schneider Electric has a rich history in motor control. How has the company’s progress paralleled the evolution of electric motors over the last century?

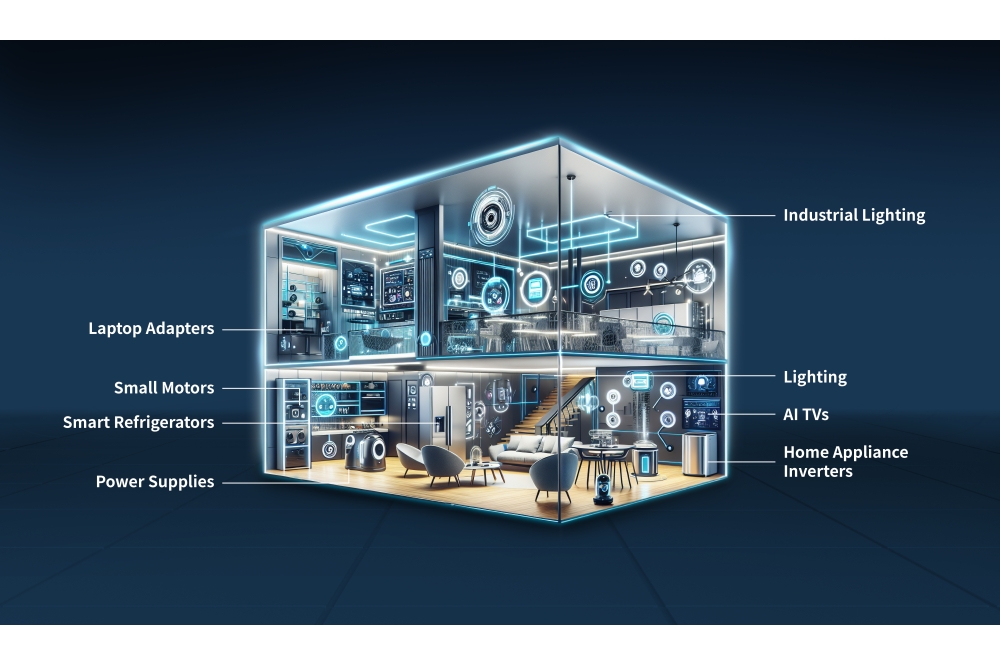

IF: It all started during the Industrial Revolution, where motors played a key role in ramping up production across industries like automobile manufacturing, as consumer demand for various devices and gadgets increased. These motors are essential in various industrial applications, whether they’re powering belts or operating lifts, all of which require precise control.

To manage these motors, Telemecanique - a French company acquired by Schneider Electric in 1988 - introduced the first BAR contactor back in 1924. This paved the way for the creation of modular contactors, and eventually led to the TeSys solution in 2000.

In 2003, Schneider Electric launched the all-in-one motor controller, offering enhanced motor control and protection for motors in industrial environments.

PEW: With the current focus on climate change and sustainability, how is Schneider Electric adapting its motor control solutions?

IF: These days, modern CEOs and company owners face a lot of challenges, especially when it comes to keeping plants running efficiently and avoiding costly shutdowns; even brief disruptions can lead to big financial losses. Another big concern is motor health, as unexpected breakdowns can be a big disruption to operations. And of course, with the big push toward decarbonisation, there’s a growing need for companies to reduce their C02 emissions. This is where our advanced solutions come in, like the upcoming TeSys Deca Advance. These smart modules connect with various communication protocols to give real-time data on electricity consumption and motor health, helping companies with predictive maintenance and preventive actions.

Our products, like the TeSys Island, also use AI and digital technologies to predict potential issues before they happen whilst optimising performance. Plus, Eco-design is also a big priority for us; we use recycled materials where we can to cut down on single-use packaging.

PEW: How does Schneider Electric support plant managers throughout the motor controller lifecycle, from design to maintenance?

IF: We offer end-to-end solutions that cover everything from design to maintenance, making the process a lot easier for our customers. Our three- tiered approach includes connected products, edge monitoring, and digital software, ensuring efficient management of entire facilities. We work closely with partners like control panel builders and OEMs to deliver integrated solutions, leveraging platforms like Aveva and EcoStruxure Automation Expert for comprehensive plant management.

PEW: What are the key benefits of the TeSys motor control range?

IF: The TeSys range excels in control, protection, and digital capabilities. It keeps systems safe from issues like arc flash and motor overburden, ensuring everything runs smoothly and safely. Our solutions also offer precise motor control, enhancing efficiency and overall performance. Customers can also benefit from valuable data analytics thanks to digital features, which help them optimise operations and make smarter decisions.

PEW: In terms of other potential benefits, what about reliability, ease of installation and advanced connectivity, for example?

IF: With over a century of industry experience, our TeSys range has earned a reputation for being reliable and efficient. We focus on providing long- lasting solutions tailored to our customers’ needs, so they can enjoy some peace of mind. We also aim to simplify the installation process with design tools, clear guides, and training.

In large industrial applications, which can use thousands of product units, our partners and contractors will install motor control centres to make sure everything runs smoothly. Our role is to enhance efficiency and make everything easier to manage.

Our products support a range of connectivity protocols like RTU, Profibus, and Ethernet. And now with offerings like TeSys Tera, we’re bringing advanced native connectivity for seamless integration into industrial automation systems.

PEW: You’ve already outlined how the motor controls are intelligent, but as AI and other advanced technologies evolve, how is Schneider Electric enhancing its products?

IF: Today everyone is talking about the power of AI to make predictions, generate content, or uncover new insights. AI thrives on data, and our products generate huge amounts of it. To put this to good use, we’re exploring ways to use this data for predictive analytics, helping our customers anticipate and prevent issues before they happen. This predictive capability will become a game changer in avoiding disruptions and boosting efficiency.

PEW: Could you share an example of how TeSys solutions are being used by your customers?

IF: A great example is in the hoisting industry, where our TeSys Island solution is used to control cranes. These applications require precise control for things like hoisting and rotation. TeSys Island simplifies these processes by integrating multiple control modules into a single system, making everything from management to maintenance so much more efficient. This solution also supports remote diagnostics and updates, which are key to maintaining uptime and operational efficiency.

PEW: How would you characterize Schneider Electric’s contribution to power electronics innovation?

IF: Schneider Electric is leading the charge in Electricity 4.0 and shaping a future that’s more digital and electric. We deliver high-quality products and actionable insights that help our customers achieve their sustainability goals. Our commitment to innovation shines through in our latest offerings, like the TeSys Tera and TeSys Deca Advance, which feature advanced communication protocols and eco-friendly designs.

As we celebrate 100 years of innovation, we’re excited to keep pushing the boundaries with new technologies that meet our customers’ evolving needs.