HexaTech wins DARPA AlN substrate contract

HexaTech, a subsidiary of Japanese firm Stanley Electric, has signed a multi-year contract with the US Defense Advanced Research Projects Agency (DARPA) as part of the agency’s new Ultra-Wide Bandgap Semiconductors (UWBGS) program.

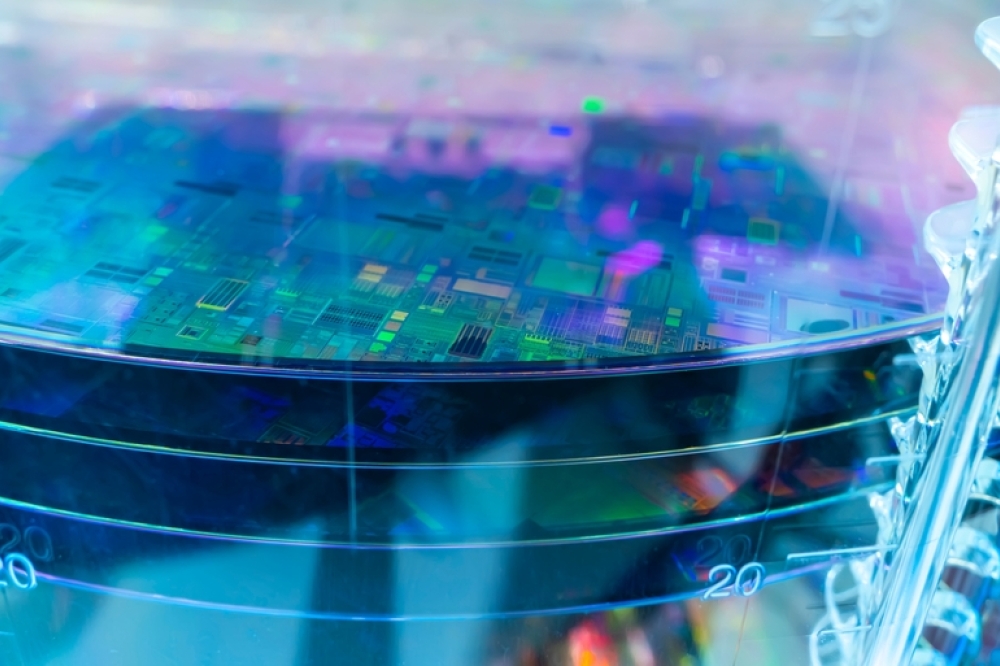

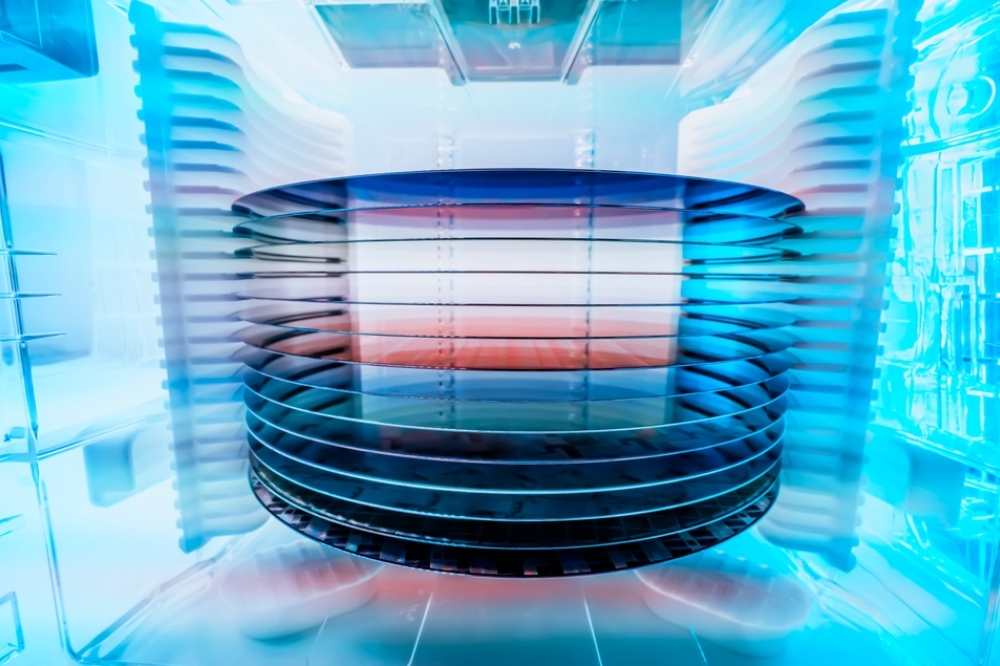

The UWBGS program aims to develop high-quality materials for realising practical UWBG electronics and applications. HexaTech’s role will be to focus on the development of 100 mm diameter, low defect density AlN substrates which are considered essential for expanding the performance/application envelope of high voltage and high frequency electronic devices.

HexaTech CEO, John Goehrke said: “We are extremely appreciative for this collaboration with DARPA and the support they are providing, as we continue to drive our AlN substrate technology forward. As the world’s leading commercial supplier of single crystal AlN material, HexaTech continues to provide cutting-edge product performance and value for our customers.”

The potential three year contract is valued at $10.2M, and builds on top of HexaTech’s previously announced 100 mm development effort, accelerating the timeline and building on the scale of HexaTech’s production process from crystal growth through substrate finishing.

Rafael Dalmau, the program’s principal investigator at HexaTech noted: “To fully support the technical potential of AlN substrates in both existing and new device technologies, expansion to 100 mm in diameter, coupled with superior bulk quality characteristics, will be critical for several reasons, including device fabrication line capabilities, device performance, and reliability.”

"HexaTech will be a supplier to all DARPA awardees tied into AlN, as well of course to others worldwide as we are now, which will significantly contribute to our business in both the near and longer term, " Gregory Mills VP, business development told Compound Semiconductor. He says the result of the program will be the direct translation of 100 mm AlN substrates into volume production, enabling industry adoption by both commercial and defence foundries.