Fraunhofer ISE opens battery research centre

The Fraunhofer Institute for Solar Energy Systems ISE has been conducting research along the entire battery value chain for many years. Now the institute has opened a centre for Electrical Energy Storage, to focus on improving the sustainability, safety and performance of battery storage systems.

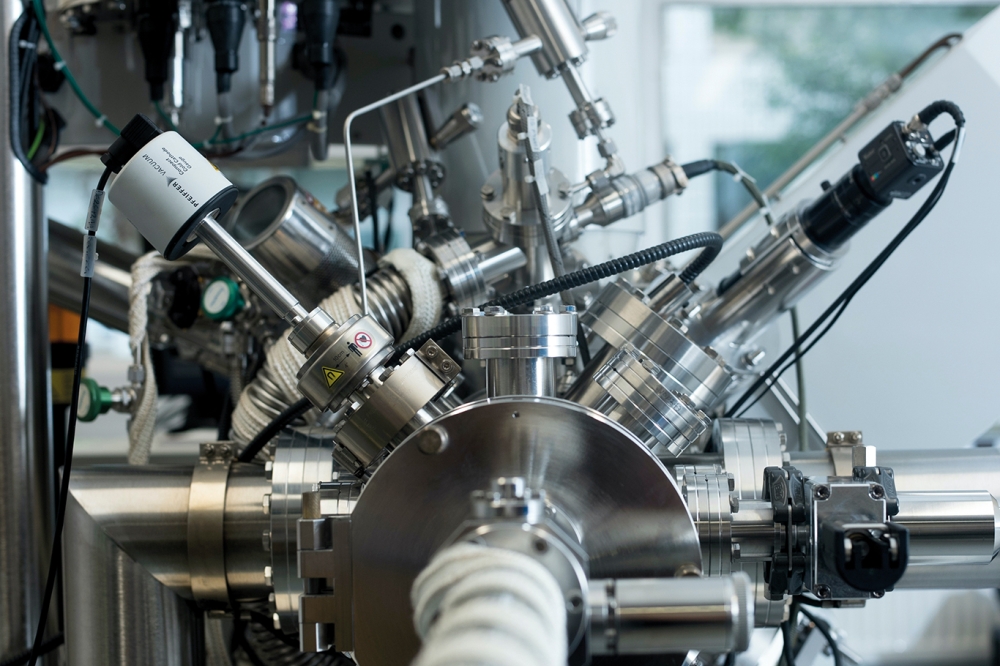

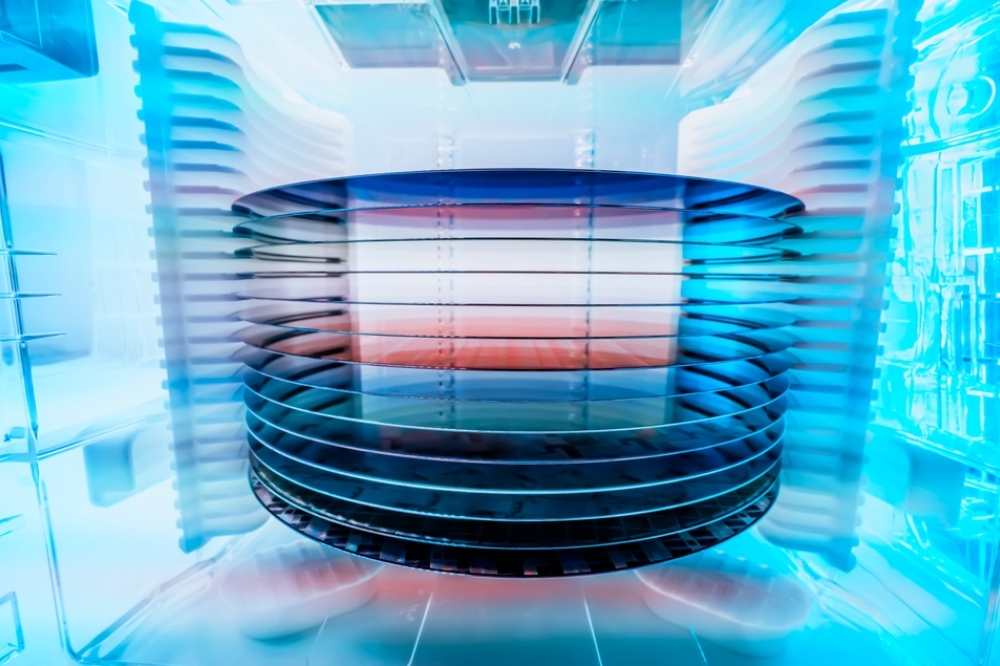

The newly inaugurated centre has a laboratory area of over 3,700 square metres and is located in the Haid industrial area in Freiburg, Germany. Within the facilities, Fraunhofer ISE will conduct research on innovative battery materials and cells, develop optimised solutions for battery systems and promote their integration into various applications, in addition to carrying out comprehensive quality assurance tests on batteries.

Fraunhofer ISE offers development and testing services and caters to a wide range of customers, from material and battery manufacturers to equipment builders up to integrators and operators for electric mobility or stationary storage systems. The institute also cooperates with industrial partners on recycling and second-life concepts.

The lab was financed by the German Federal Ministry of Education and Research (BMBF) and the Baden-Württemberg Ministry of Economic Affairs, Labour and Tourism, each of which contributed €9 million. "We are grateful for this funding, as it has enabled us to build a research infrastructure with state-of-the-art characterisation instruments, industry-oriented process equipment and unique facilities. We can now develop materials, technologies, production processes and applications with a focus on the practical relevance, carrying this out together with our industrial customers or in close collaboration with Fraunhofer's battery cell research production," explains Institute director Hans-Martin Henning.

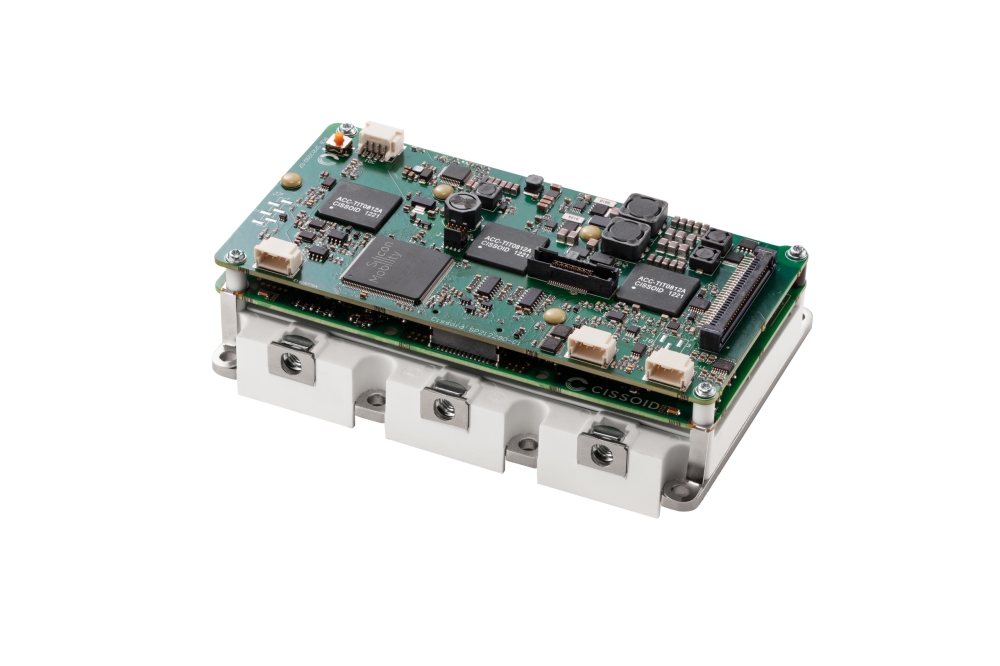

The building itself also serves as a living lab for research. In the 'Haid-Power' project, funded by the state of Baden-Württemberg, the centre received a modular hybrid battery storage system with a capacity of 836 kWh, which, together with an 850 kilowatt photovoltaic system on the flat roof, supports the building's energy supply.

With this system, battery-based solutions for commercial and industrial use as well as new operating strategies like intelligent load management can be tested under real operating conditions. As part of the BMBF-funded 'ecoLEPu' project, a fast-charging station with buffer storage is being installed to test second-life batteries for use in high-performance applications.

Research focus: sustainability, safety, performance

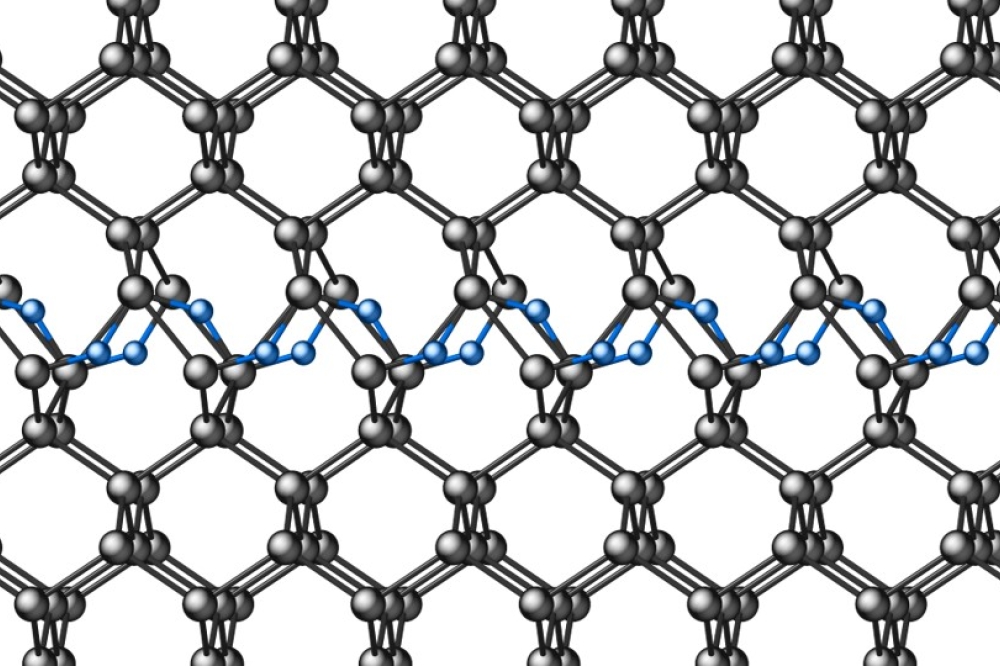

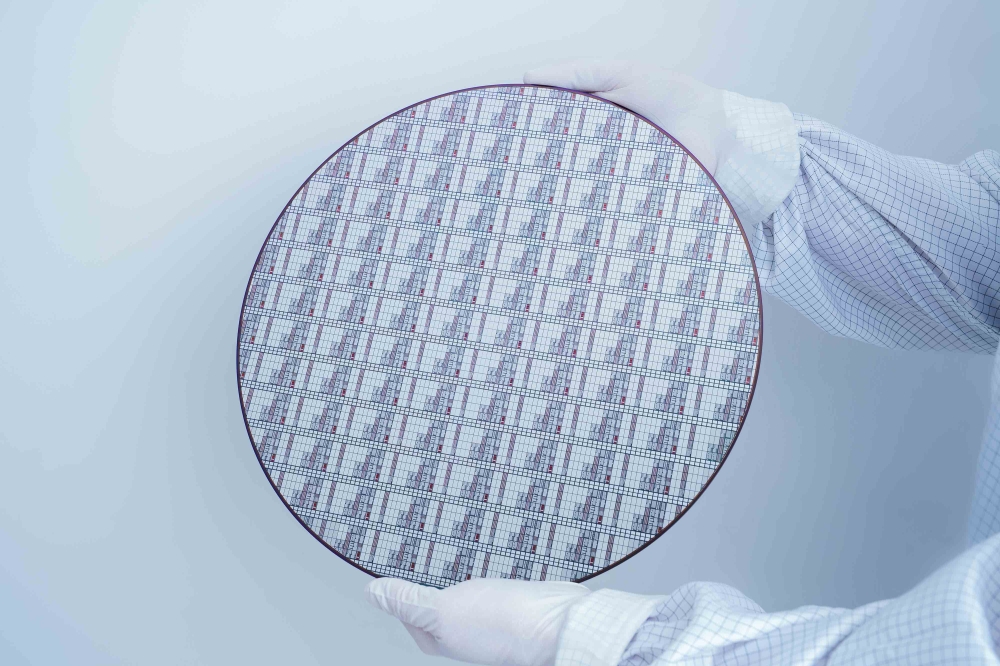

Within the framework of the energy transition, between 300 and 800 gigawatt hours of stationary battery storage are to be installed in Germany by 2045, depending on the scenario. To this end, Fraunhofer ISE is addressing the sustainability of batteries in its research, for example, by investigating alternatives to lithium, developing sustainable production processes and looking at second-life use and end-of-life recycling. In the current 'PRONTO' project, for example, researchers are working on a sodium-ion battery technology that does not contain critical raw materials and can be manufactured in Baden-Württemberg.

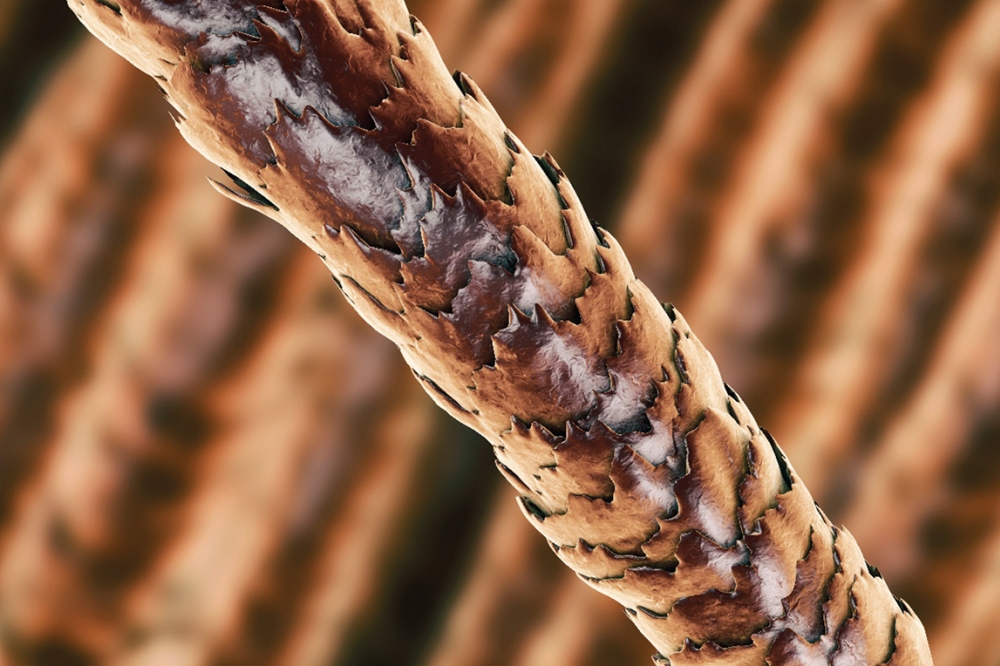

With the rapid development of the battery market for both mobile and stationary applications, the need for investigations and tests on battery cells and systems continues to increase significantly. By reducing costs and increasing performance, numerous potential applications for electrical energy storage systems can be opened up. Here too, researchers are working along the entire chain from materials to operational management to improve energy density and performance, the number of cycles and charging behaviour.

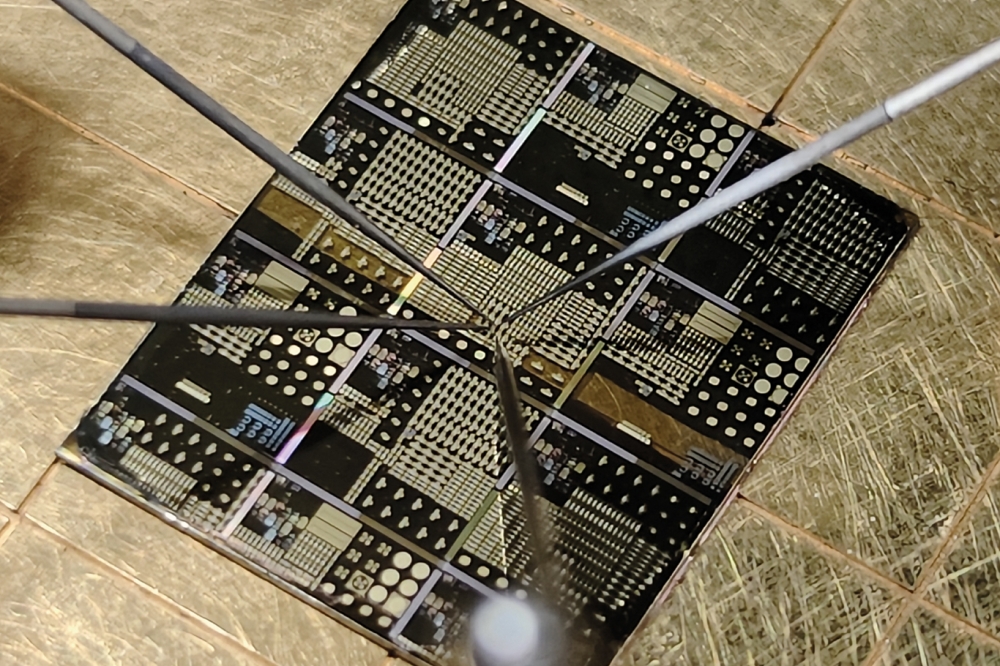

"In our new centre, we are able to perform characterisation measurements from the microstructure level up to the overall system level, which enables us to identify defects and safety risks at an early stage. A safety issue that we are researching currently is propagation, a chain reaction in which one battery cell after another experiences thermal runaway, releasing large amounts of heat," explains head of department Daniel Biro. “Our test team now has access to a unique laboratory infrastructure with sophisticated safety equipment, in which we can perform non-destructive tests and explosions on test specimens in special reinforced test rooms.”