MacDermid Alpha shows next gen bond pads at PCIM

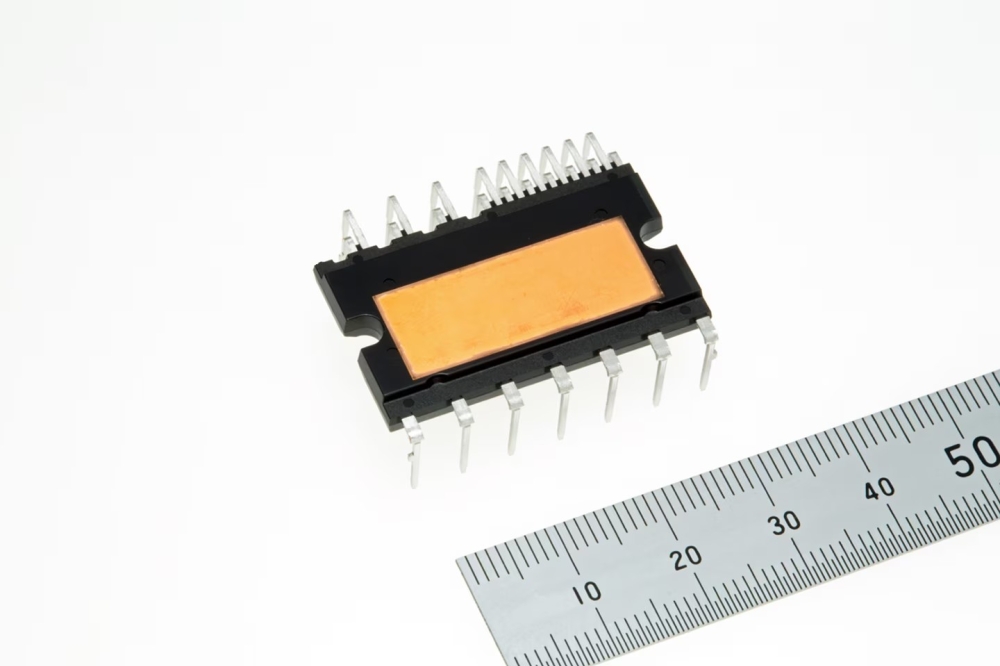

MacDermid Alpha Electronic Solutions, a US maker of electronic assembly materials, will introduce its latest bond pad innovations at PCIM Europe 2025 in Nuremberg, Germany, from May 6 to 8.

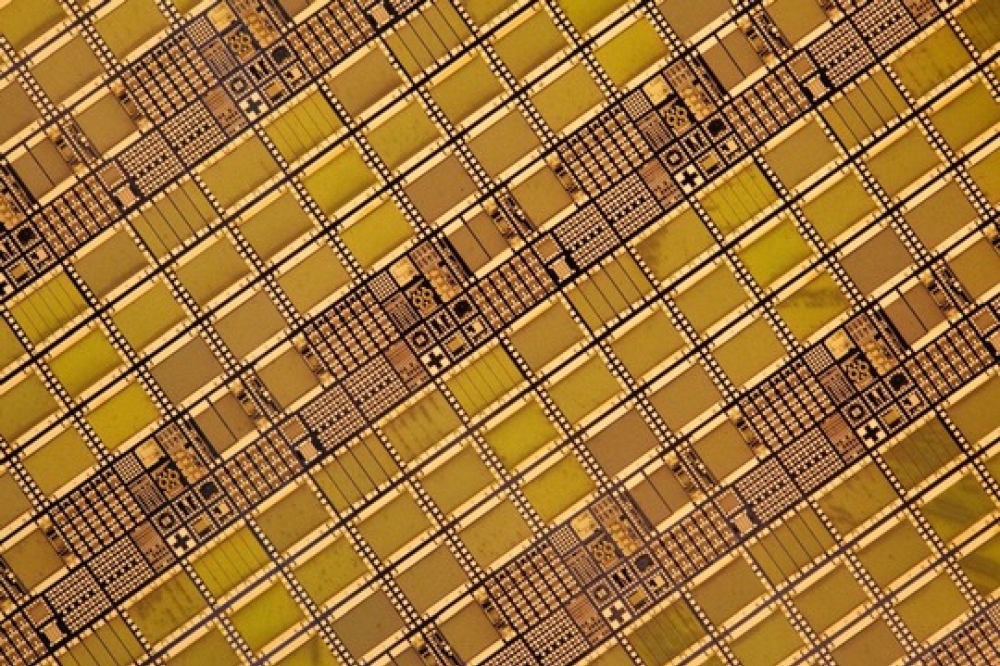

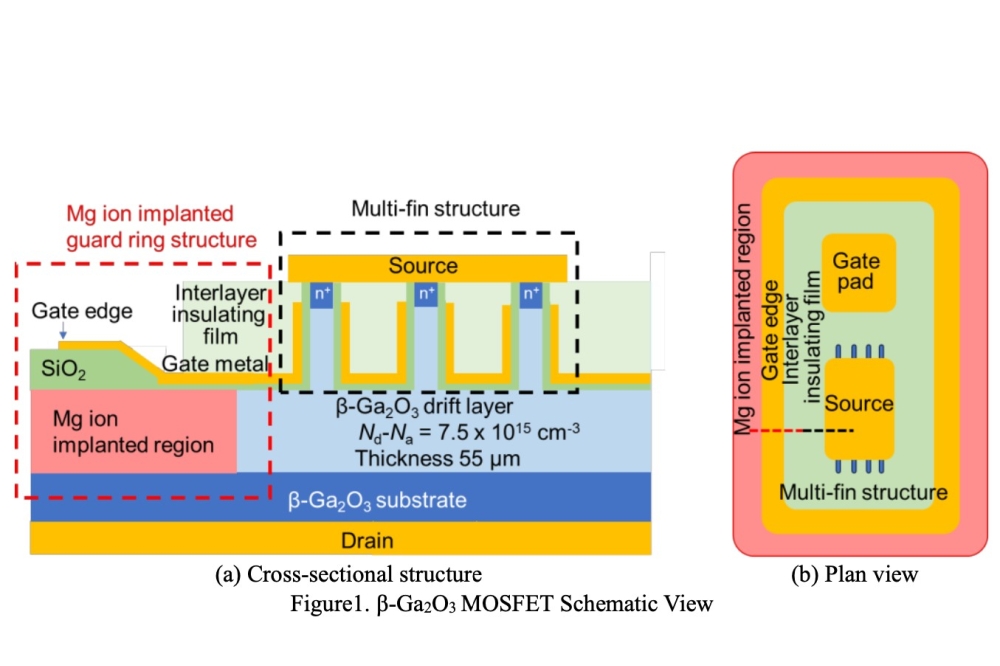

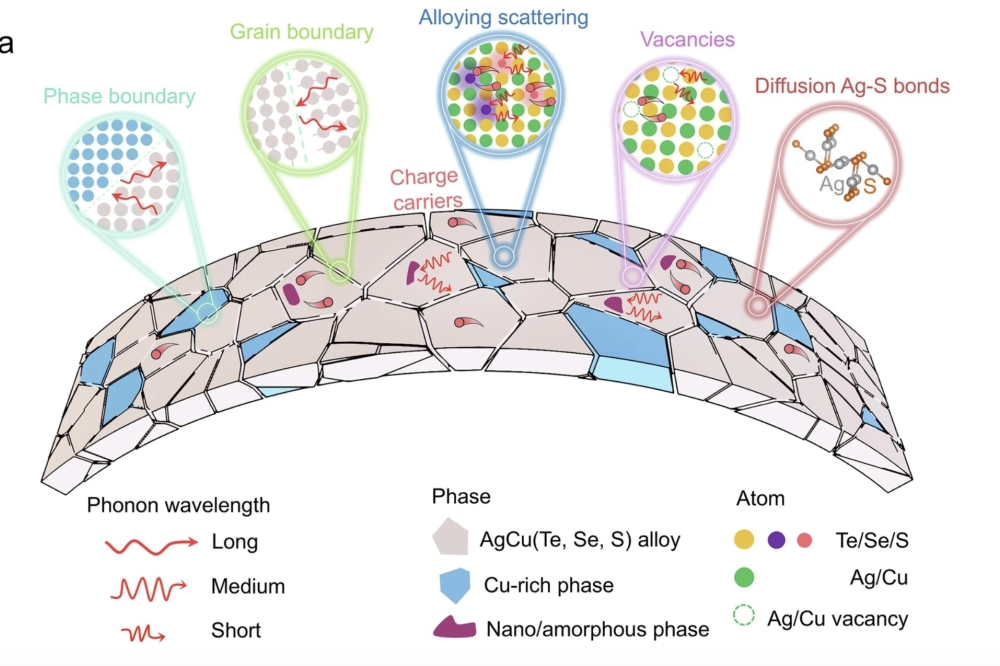

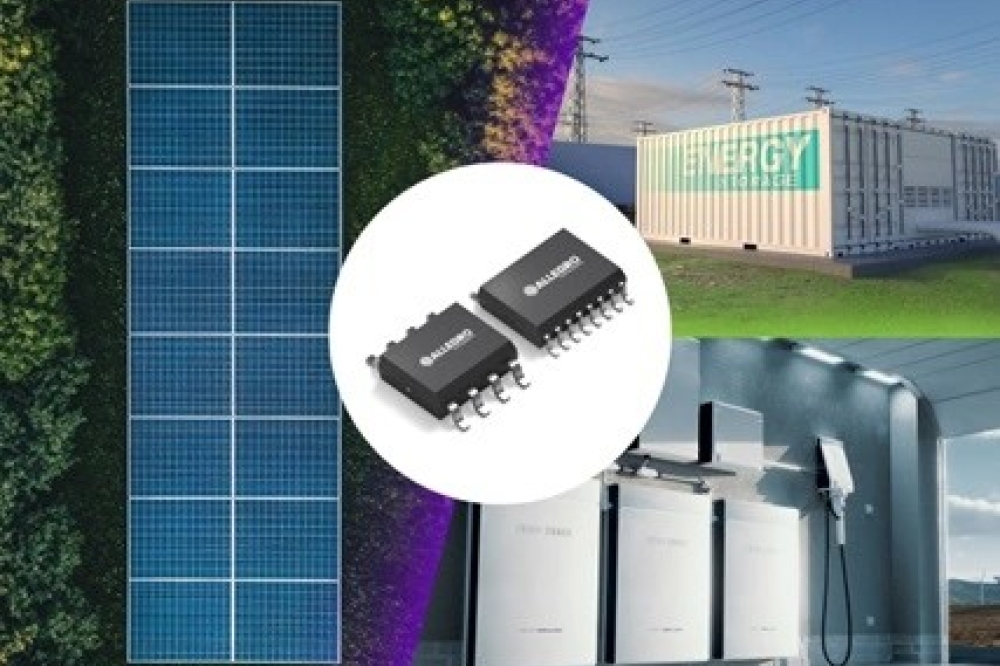

Bond pad metallisation serves as the critical interface between semiconductor dies and interconnects in power devices, automotive electronics, and advanced semiconductor packaging. As the industry moves toward higher power densities, finer pitch designs, and stricter reliability requirements, the demand for optimised bond pad materials has never been greater.

MacDermid Alpha’s latest bond pad solutions are said to deliver superior adhesion, enhanced conductivity, and improved corrosion resistance, ensuring higher yields and long-term reliability in EV power modules, renewable energy systems, and other high-performance applications. These innovations will be featured at PCIM 2025, offering attendees a first-hand look at their capabilities.

Improved performance and reliability

John Hynek, global product manager for power wlectronics, will present ‘Improved Reliability for Die Top Connection in Power Electronics’ at the PCIM exhibitor stage. His session will explore the latest bond pad advancements and their impact on wire bonding as well as high-reliability interconnects. Attendees will gain insights into material performance enhancements and integration strategies for next-generation power electronics.

“With the rapid evolution of EV powertrains, renewable energy systems, and next-generation semiconductor packaging, bond pad materials play a crucial role in interconnect performance and reliability,” said John Hynek. “At PCIM Europe 2025, we are excited to showcase how our advanced bond pad solutions empower manufacturers to tackle higher power densities, reduce form factors, and extend product lifecycles.”

Attendees visiting MacDermid Alpha will also experience live demonstrations, technical discussions, and in-depth product showcases.