The second electrical revolution?

Solid-state based, DC extraction directly from AC mains without the

use of rectifier bridges, transformers and high voltage, bulk

capacitors.

BY THAR CASEY, AMBERSEMI CEO

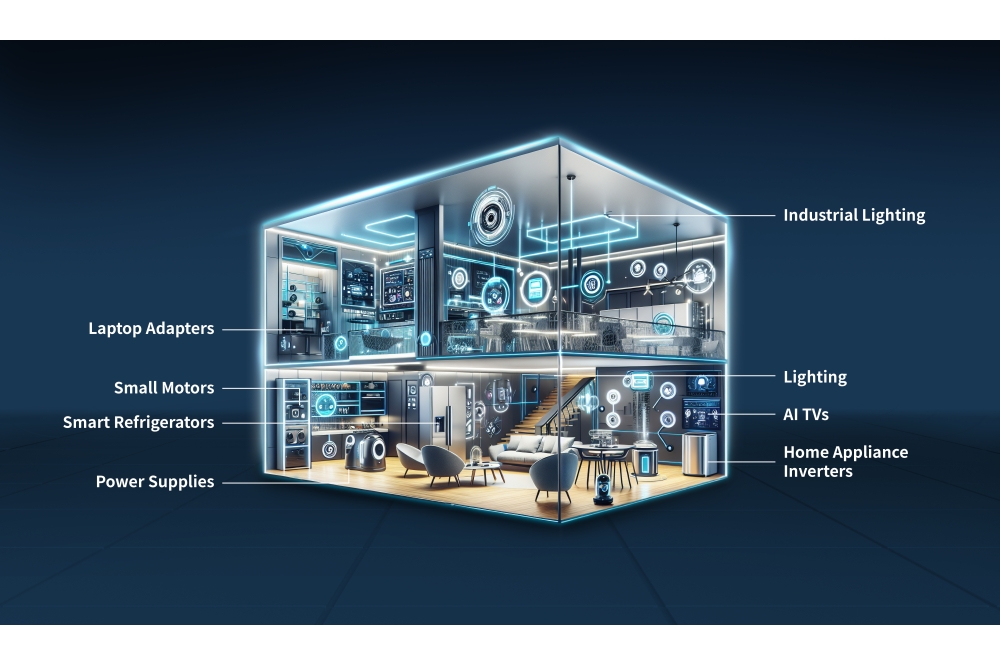

IT’S JUST POWER…or is it? With the continued flourishment of intelligence and automation in homes, workplaces and public spaces, smart technology in buildings has continued to evolve at a breakneck pace over the last few years. However, the industry that powers these various devices and electrical endpoints accessed daily by billions of people in residential, commercial, and even industrial buildings around the world, has ironically remained largely stagnant for decades.

But why has the power electronics sector lagged so far behind the very products it supports? One reason: slow, uninspiring innovation to 1950s-era industry standard components and limited topology options, lacking the kind of true disruptive technology breakthroughs that pushed so many other categories forward into the 21st century.

The good news? There’s an opportunity for power electronics to finally evolve (modernize) their power architecture and fundamentally break through the limitations they face from legacy status quo power products; it’s an opportunity to tap a once in a generation fundamental architecture change - an upgrade and modernization of the core technology foundation that powers these solutions globally.

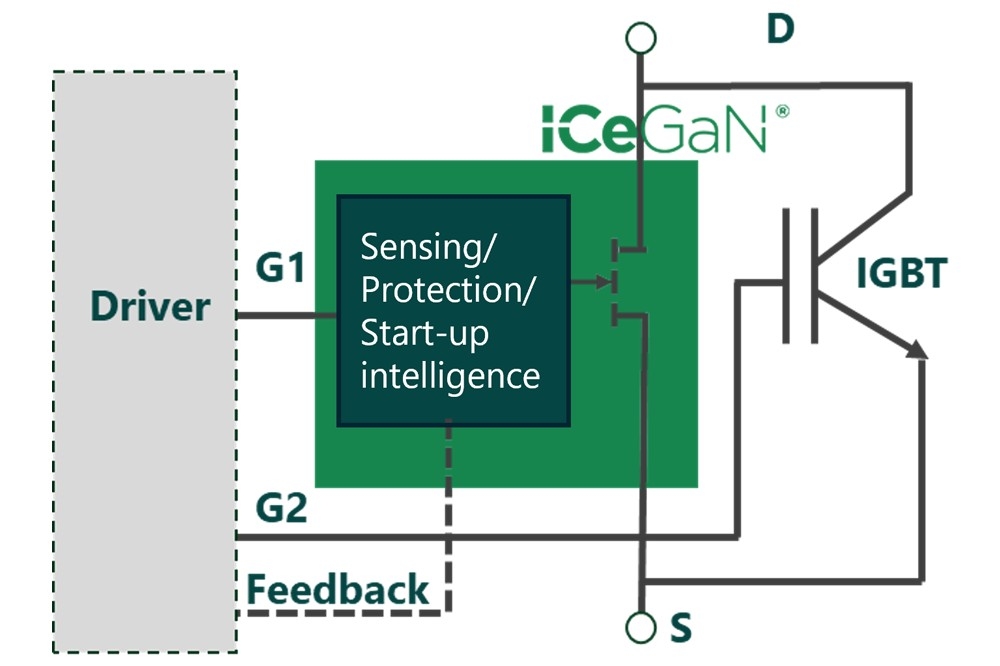

How so? With the adoption of modern, solid-state silicon chip solutions that digitally manage electricity, breakthrough functions and feature expansions are now possible in electrical products without a change in standard form factors. This includes the capabilities of AmberSemi’s AC Direct DC Enabler™ architecture to extract DC directly from AC mains without the use of rectifier bridges, transformers and high voltage, bulk capacitors.

This breakthrough solid-state power technology allows for new electric product design possibilities and intelligence capabilities that were previously unatainable. And once industries complete the shift to solid-state solutions, they never turn back, as with categories like tube TVs conversion to solid-state TVs or computer’s spinning magnetic hard drives to solid-state hard drives.

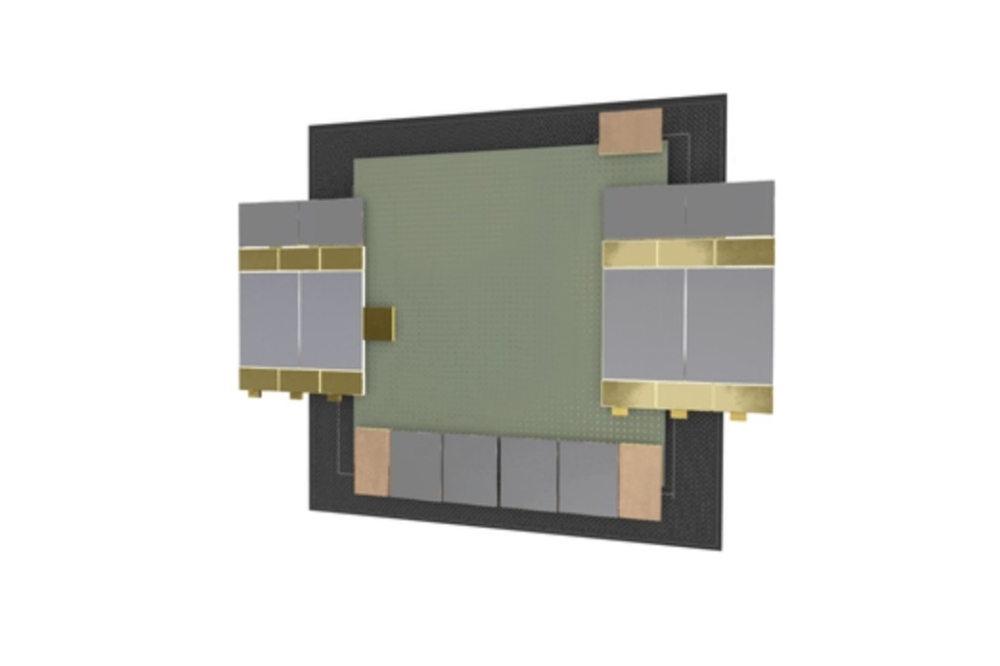

At its core, this generational architecture upgrade is a classic Silicon Valley semiconductor story. It’s the consolidation of old-school, outdated technologies into a tiny silicon chip, capable of replacing the function of standard electromechanical components. And, in the process, it enables more features potential and much beter operational flexibility, all with smaller size footprint and improved reliability that comes from solid-state architecture.

However, the potential impact of this “second electrical revolution,” led by companies like Amber Semiconductor, is far more profound than merely being another step in the iterative progression that has defined this space for years. Let’s dive into the specifics behind how this technology will truly harness the potential of innovation.

Footprint Efficiency, power density and configurability

Today, electrical products companies are feature constrained by BOTH power delivered and product form factors. Any increase in feature scope is highly likely to require an increase in form factor size which can be costly at best - not viable at worst.

AmberSemi’s breakthrough digital control of electricity, integrated into a semiconductor IC device allows for more compact, more dynamic power designs, and represents a generational architecture upgrade to power technology across the electrical product landscape. And it delivers such capabilities without requiring deviation from universal form factors of end products. The dramatically smaller system size enabled by AmberSemi’s AC Direct DC Enabler IC’s, for example, open physical space for more features and/or slimmer product form factors, which can generate cost savings and provide a myriad of benefits.

In fact, AmberSemi’s AC Direct DC Enabler IC’s are the industry’s most size-effective and claims the industry leading power density at 5 Wats per 0.21 in3 (1.47 cm3). This creates enhanced power density, making solid-state architecture particularly appealing in applications where space is limited, such as portable electronics, circuit breaker boxes, power distribution units, and even electric & traditional gas-powered vehicles.

In addition to AC Direct DC Enabler ICs’ competitive breakthrough benefits (smaller, more modern and more programmable), the devices offer additional functionally and configurability by providing access to the internal programmable registers through the embedded Serial Peripheral Interface (SPI). When paired with a processing unit, the result is an intelligent power conversion solution, enabling real-time reporting on a range of internal operations, such as monitoring of alarm events and data-logging of sub-system loads.

Reliability and durability

Solid-state architecture enables power electronics companies to achieve higher levels of reliability and durability compared to traditional solutions. The AC Direct DC Enabler™ architecture uses lower voltage rated capacitors than traditional systems, which means our IC can support ceramic, polymer, and electrolytic capacitors. Therefore, designers have flexibility to more easily optimize their design for performance, cost, space constraints, and reliability.

A dramatically lower component count also contributes to increased reliability, as well as enhanced sustainability. With up to 50% fewer components for the power delivered versus standard power supplies, AmberSemi’s unique AC Direct DC Enabler ICs’ technology reduces electrical and thermal stress of critical components, enabling efficient heat dissipation and reducing the risk of component failure due to overheating. It even offers the ability to use ceramic capacitors instead of electrolytics in cases where reliability is of the highest importance (as in switch mode power supplies.) As a result of all of these and other capabilities, electrical products companies can leverage more reliable and longer-lasting power solutions that truly enhance the quality, and value, of their products.

Flexibility and scalability

Modern solid-state power architecture solutions, such as AmberSemi’s AC Direct DC Enabler™ ICs, enable a change in design engineers thinking about what is now possible in their products. The reason for this is that solid-state architecture and digital management of electricity offers greater flexibility and scalability compared to traditional power electronics solutions. This flexibility opens up new possibilities for design engineers to optimize their products for specific applications, meet a wide variety of customer requirements, and accommodate future technological advancements - while keeping the same solid-state system architecture /device. With a wide input voltage range of 24- 277VAC AmberSemi’s AC Direct DC Enabler ICs allow a single design to be used across a global product portfolio.

In future designs, the input voltage independence of Amber’s technology will provide even more value to higher voltage industrial applications in which traditional products struggle.

Additionally, products like AmberSemi’s AC Direct DC Enabler™ ICs offer the opportunity for consolidated architecture. The chip can be easily integrated into a variety of generic and modular design architectures, allowing for scalability and system expansion, where architecture can be more dynamic and have broader power application. In addition, it uniquely delivers global compatibility within a single device. Design engineers can leverage this feature to develop solutions that can adapt to varying power demands, creating the potential for end product line SKU reduction, and allowing them to be adaptable to changes in the system architecture.

In the end, integration of AmberSemi’s new power management architecture provides customers with versatile and future-proof power supply solutions, while also enabling the opportunity for streamlined end product footprints with the power flexibility to also include more functions.

Dynamic power & sustainability

In addition to being smaller, safer, and more reliable, the power derived from AmberSemi’s AC Direct DC Enabler IC’s are far more dynamic because electricity is managed digitally, which enables substantially more control. It delivers dynamic power through software, enabling configurable output voltage ranges with automated mode switching to optimize efficiency for all power outputs.

By embracing solid-state chip architecture, power module companies can actively support the transition to a more sustainable energy landscape. This advantage can be attained because the architecture, as discussed above, requires fewer components and is more durable - reducing the need for replacement parts, which contribute negatively to the carbon footprint through production emissions.

Conclusion

The opportunity for electrical product companies to upgrade their power supply solutions to solid-state is not just another iterative step in the longstanding pattern of technological advancement – it’s a generational architecture breakthrough. Solid-state transformation changes the design calculus of electrical engineering in ways that were previously thought to be: impossible. History tells us that once market categories move to solid-state, they convert quickly, and never look back to the legacy old tech standards. With AmberSemi’s innovations knocking on the electrical product industry’s door, the dawn of a second electrical revolution may be right around the corner.