The Benefits of Industrial Networking in Wind Power

Brian Roth, Marketing Product Engineer at Antaira Technologies discusses the unique networking challenges of wind towers

Clean renewable energy sources such as wind have been utilized by humans for hundreds of years. Until recent advancements in technology and power generation efficiency, windmills were not extensively used for power generation in wind farms. Although today, society has been developing and adopting more green power sources such as wind power. The Bureau of Land Management determined that for over a decade, wind energy has topped the charts as the fastest growing energy technology worldwide. In fact, wind power has enjoyed an average yearly growth rate of more than 30 percent and experienced a 44 percent growth in 2014 alone.

Running any business efficiently is a no brainer but when the business is power generation, efficiency should be a top priority. It is no secret that optimal efficiency is achieved through advanced technology as well as optimum oversight and control of the application. Technology in windmills have seen advancements not only in the bearings, rotor components, collector rings and magnetic wedges but also in the overall weight of the turbines; allowing for taller windmills that are able to access better and more stable wind steams. As the size and scope of wind farms increase, so does the need to accurately control and monitor the overall scope of the power generation station. The monitoring of equipment resources allows for fine tuning and adjustments to be continuously made. This is critical for a dynamic environment such as a wind farm where one day is rarely the same as the next.

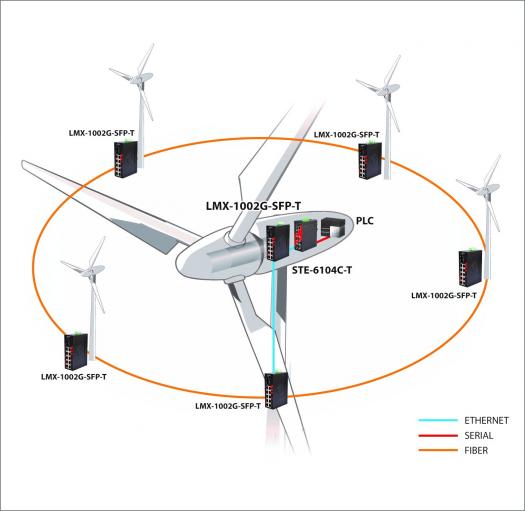

Due to the locational restrictions of wind farms, finding a geographical area that provides suitable weather conditions for the wind tower is critical. A windfarm is often times deployed in semi-remote areas where the monitoring of data needs to be sent to a more centrally located control room. It is extremely important to be able to monitor each windmill to ensure that not only is power being generated but also that negative power is not being consumed by the wind tower. Serial device servers and managed Ethernet switches within the wind tower are able to collect and provide data from the controllers, gear boxes and anemometers for oversight at the command centre. The best type of Ethernet networking architecture to use for this application would be a fiber optic ring. Fiber optics will easily be able to create a communication link over a long distance from the control room to the wind farm itself. Using fiber optics also protects the data from being compromised from the electromagnetic interference generated by the wind turbine. The utilization of managed switches to form a ring architecture will provide additional benefits. A ring topology often times uses less cabling than a typical star topology. However, the greatest benefit of implementing an Ethernet networking ring would be the data redundancy that it provides. A networking ring utilizes a redundant data path, preventing the loss of control and data to the windfarm despite any single link failure.

Just as important as the efficiency of the windmill itself; is the reliability of the networking equipment used for the control and monitoring of the entire wind farm. Industrial grade networking equipment is a must for any wind farm application. With a minimum of 100,000 hours as the mean time between failures, industrial grade equipment offers the reliability of an extended lifecycle over commercial equipment. Wind farms face a wide variety of environments as well, ranging from the hot deserts of Arizona to the cold plains of South Dakota. The temperature ranges of these environments might be extreme for some humans but they fit perfectly into the -40°C to 75°C operating temperature of industrial networking equipment. Furthermore, industrial networking equipment has been specifically engineered to withstand the constant shock and vibration generated by the windmill that can quickly degrade and break solder joints of lower quality electrical products.

Clean, green, renewable energy such as windfarms will continue to increase in quantity due to the clear advantages they have over more detrimental energy sources. Wind towers present unique networking challenges that require a mixture of serial, Ethernet, fiber-optic and even wireless communication solutions. Industrial grade networking equipment offers the degree of reliability and protection needed for the unique challenges of collecting accurate data from wind farms.