Fraunhofer inverter project boosts EV performance

Dauerpower project with Porsche and Bosch uses SiC and novel packaging to achieves up to 30 percent performance increase

Fraunhofer IZM is working with project partners Porsche and Bosch, in a project called Dauerpower, to develop an electric inverter that can work at a lower operating temperature thanks to optimised cooling management, resulting in a lower power loss.

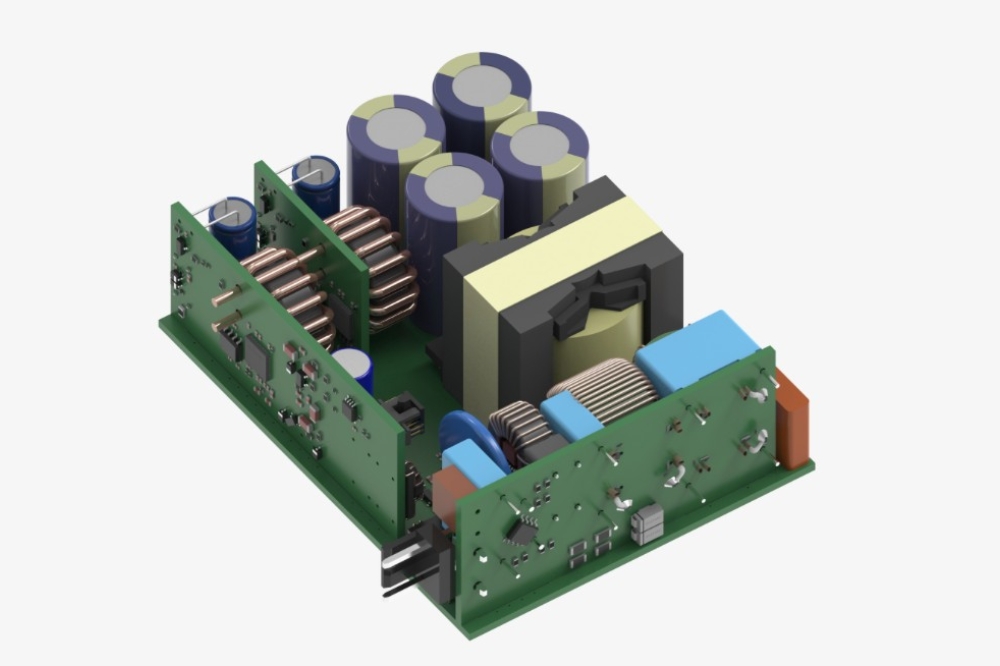

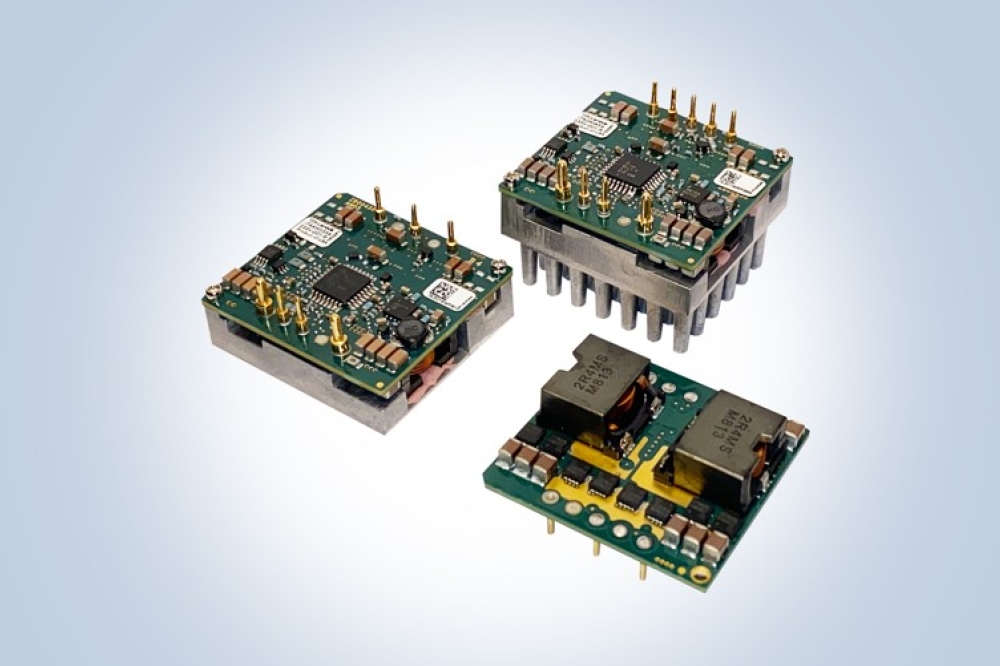

The compact three-phase drive inverter has a high continuous output of 720 kW or 979 horsepower and a rated current of 900 A

Eugen Erhardt, head of the project at Fraunhofer IZM, assesses the performance of the new system: “Compared to existing silicon-based inverters, our approach achieves an increase in performance of between 20 percent and 30 percent.” The researchers achieved this increase in power density through the thermal optimisation of advanced materials and optimised embedding processes in production. Erhardt's group had already dealt with these in the SIC efficient predecessor project.

To prevent the passive components of an inverter, such as capacitors and copper elements, from being damaged by heat build-up, conventional systems throttle their maximum output in continuous operation.

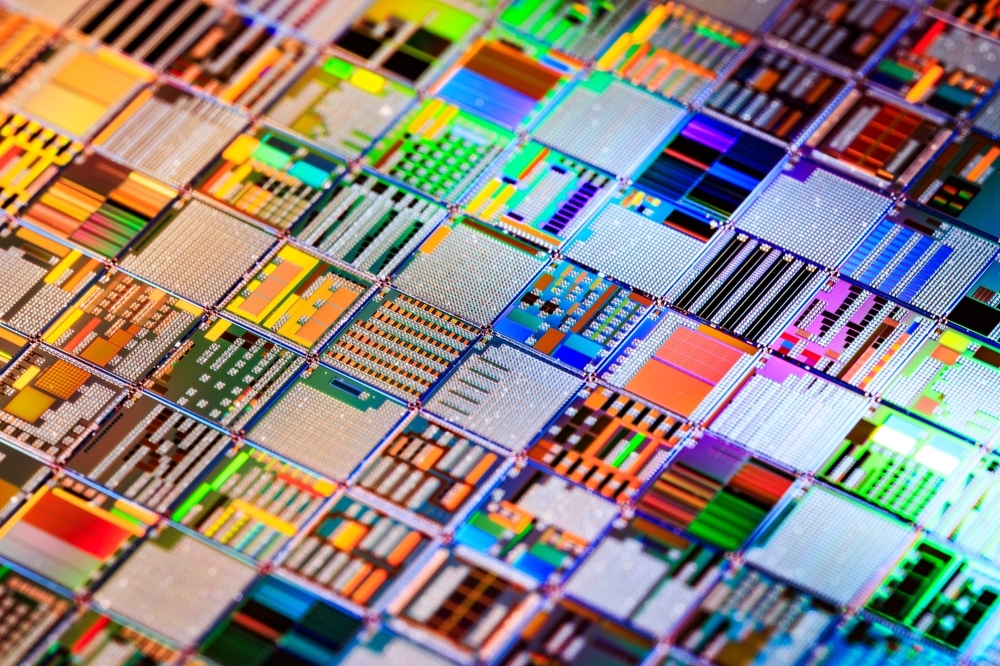

The system developed by Fraunhofer IZM avoids this by using SiC transistors. Two of these SiC transistors are applied directly to a ceramic substrate at Fraunhofer IZM using an innovative prepackaging process. These prepackages can then be flexibly embedded in conventional PCBs. Thanks to the thin design and a reduction in the materials required, less mechanical stress and more uniform deformation behaviour occurs in case of heat exposure. In addition, the segmented ceramic substrates make optimum use of the limited space available to best meet the specific requirements of the automotive industry.

Copper cooling elements from the 3D printer

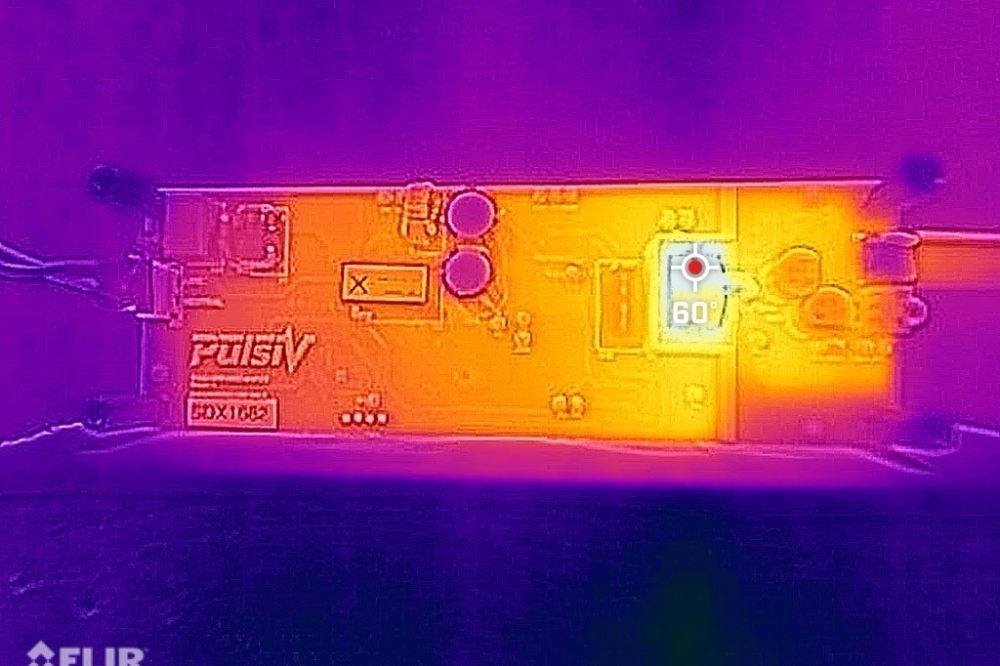

In addition to the optimised materials, the researchers also looked at how to cool the individual components more efficiently. The better the cooling effect, the less expensive semiconductor material is required, as the chips can be arranged even more compactly.

The researchers' aim is to achieve a high level of thermal integration of the various semiconductor elements, as well as passive components such as capacitors and copper conductors. For this purpose, the temperature-critical components are connected directly to the cooling system via silver sintered connections and thermally integrated in the best possible way: Thanks to a parallel arrangement, the cooling liquid reaches all heat sinks and connected semiconductor elements simultaneously, and the thermal energy is dissipated evenly.

Copper is also being used for the first time in a 3D printing process to manufacture the cooling elements, allowing the excellent thermal conductivity of copper to be combined with the full flexibility of 3D printing, instead of only being able to access aluminium heat sinks as before. Compared to CNC milling processes, 3D printing allows a great deal of freedom with regard to the design of the cooling channel and, in turn, optimum utilisation of the limited installation space.

High modularity of the prototype

In addition to advances in materials and production processes, the scientists were also able to achieve greater modularity of the individual elements for the prototype. While the concept envisaged in the previous project was still based on a solution in which all components were permanently connected to each other, the elements of the inverter can now be replaced and repaired more easily as sub-modules.

Following a simulation phase, the prototype is currently under construction and will ultimately undergo an extensive testing process at Porsche AG in order to one day find its way into series production.

The Dauerpower project was launched in 2021 and received funding of €1.2 million from the German Federal Ministry of Economics under the reference number 19I21023C.