SiC MOSFETs: Understanding the benefits of plasma nitridation

Engineers from Osaka University are offering new insights into the benefits of their novel approach to forming the key interface for SiC MOSFETs.

The team has just determined that its approach – involving plasma nitridation of the SiC surface, sputter deposition of SiO2, and post-deposition annealing – reduces the interface state density near the conduction band edge by more than an order of magnitude and delivers a substantial increase in immunity to positive gate bias stress.

These valuable findings highlight the benefits of moving away from standard approaches to making SiC MOSFETs, which despite significant commercial success suffer from a high on-resistance and poor reliability, according to the team from Osaka. This team attributes those weaknesses to a high interface state density and near-interface traps.

The Osaka University researchers say that interface nitridation with NO is widely used to reduce the interface state density and passivate defects. However, this approach is far from perfect: the reduction in the density of interface states is limited, probably due to saturation of nitrogen content at the interface; and there are reliability issues, such as a strong drift in threshold voltage with gate bias stress.

To address these concerns, the engineers from Osaka are pioneering an approach that suppresses nitrogen incorporation into SiO2 while minimising oxidation of SiC. Their three-step process involves: plasma nitridation of the SiC surface; sputter deposition of SiO2; and post-deposition annealing under CO2.

According to the team, one of the benefits of this approach is that SiC is directly nitrided by a high-density plasma, enabling a high proportion of nitrogen atoms to be incorporated at the SiC surface. Additional merits of their approach include sputter deposition of SiO2 in a pure argon atmosphere to minimise SiC oxidation, and a post-deposition anneal that reduces the density of defects in the SiO2 dielectric.

The researchers previously established that their process trebled the density of nitrogen atoms incorporated at the SiC side of the interface, lowering the density of interface states to 1 x 1011 eV-1 cm-2. However, they had not investigated the impact of post-deposition annealing on device characteristics.

They have just addressed this issue with a thorough investigation of the roles played by the particular gas employed and the temperature that’s adopted for the post-deposition anneal. For this work, they produced SiC metal-oxide-semiconductor capacitors, using n-type SiC (0001) epilayers with a donor density of 1 x 1016 cm-3. Following wet cleaning, they nitrided the surface of SiC for 30 minutes at 350 °C with a high-density nitrogen plasma at 1.4 x 103 Pa, before sputtering a 30 nm-thick film of SiO2 in a pure argon atmosphere. The final step involved a post-deposition anneal for 30 minutes under either CO2 or argon at a temperature between 1050 °C and 1250 °C.

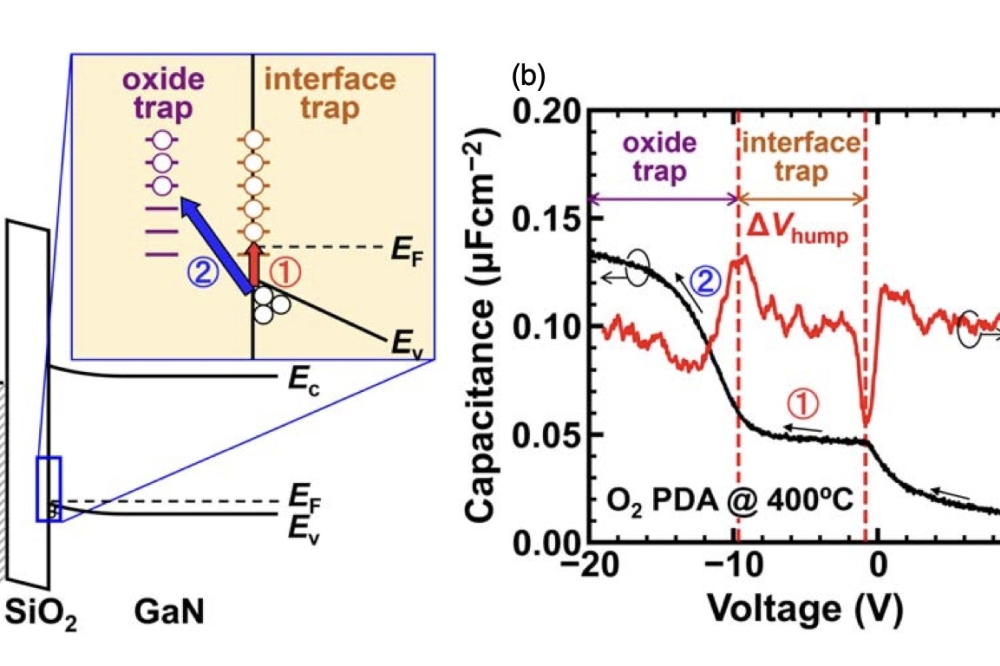

Comparing capacitance-voltage curves for annealing under CO2 at different temperatures showed that carrying out this process at 1050 °C ensured sufficient electron accumulation. However, this technique led to hysteresis and stretch-out due to interface traps. Both concerns were not found in capacitance-voltage plots for devices with a 1250 °C anneal, suggesting a significant reduction in interface traps.

The researchers also observed a negative shift in the capacitance-voltage curve with increasing anneal temperature, indicating the presence of positive fixed charges at the interface.

Additional investigations by the team considered the trapped charge density and the energy distributions of interface states. For annealing under CO2, the trapped charge density plumets with increasing annealing temperature. Under argon, the fall in trapped charge density is notably smaller, leading the team to conclude that the reduction in charge density is not simply an annealing effect, and involves a reaction of CO2molecules with interface traps.

Studying the energy distribution of the interface state density revealed that this fell with increasing temperature when annealing under CO2. Switching to argon led to an insufficient reduction in interface state density, showing that the benefits of the team’s process are not just plasma nitridation and minimised oxidation – they also include defect passivation by a CO2 post-deposition anneal.

The team have also carried out stress tests, applying a positive stress bias for up to 2000 s at field strength of 5-8 MV cm-1. This investigation revealed that a higher annealing temperature under CO2 increases the immunity of the device.

Reference

H. Fujimoto et al. Appl. Phys. Express 17 116503 (2024)