3D-Micromac equips Infineon fab

3D-Micromac AG, a provider of laser micromachining and roll-to-roll laser systems for semiconductor, photovoltaics, glass, and display industries, has announced that Infineon Technologies Dresden has ordered one of 3D-Micromac's first microVEGA FC laser-trimming systems.

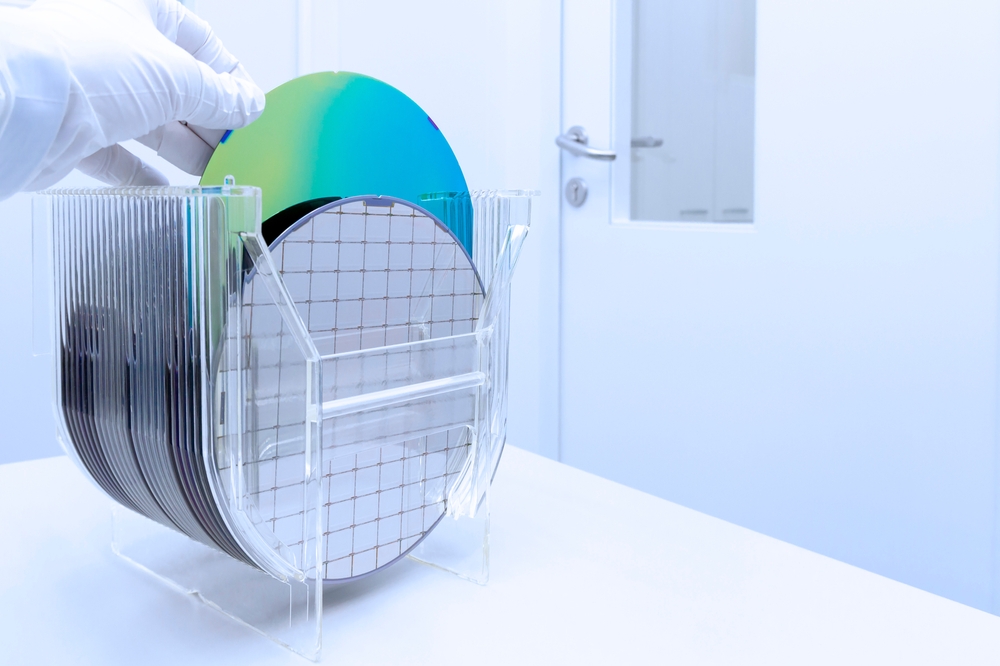

Designed specifically for Infineon, the order followed a joint-development project in which 3D-Micromac's laser-trimming process was transferred into a mass-production-capable laser system. (The microVEGA system has already been used successfully to process up to 300-mm (12-inch) semiconductor wafers in several industrial use cases.)

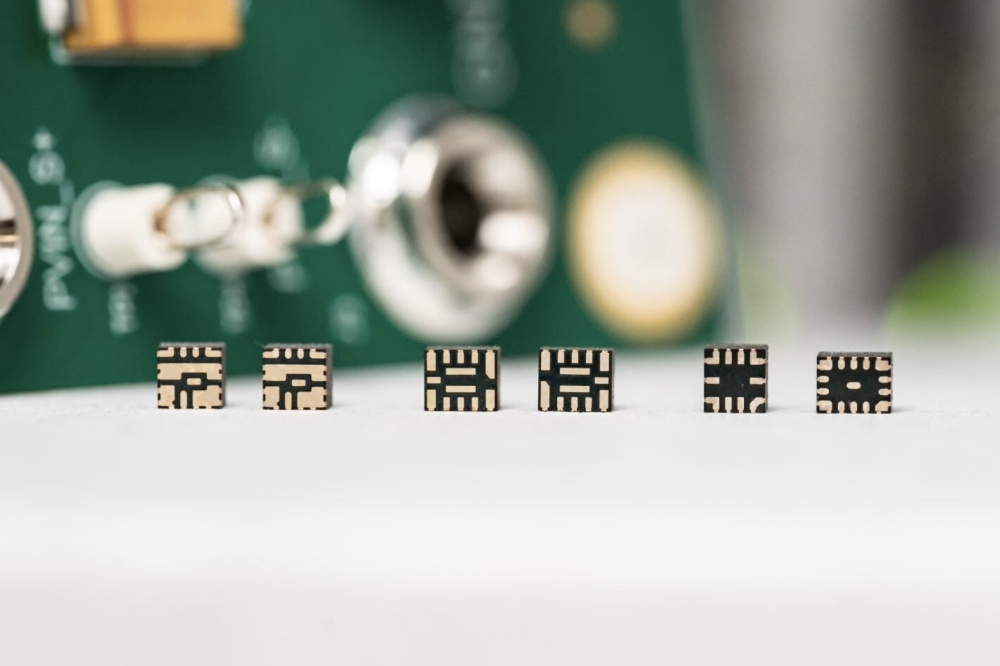

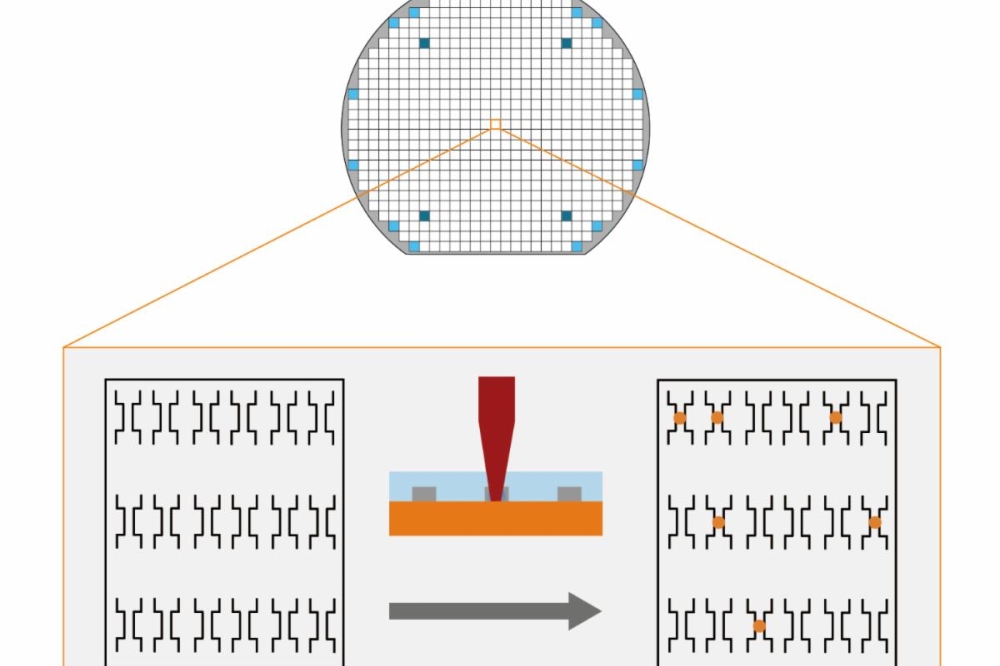

The laser beam of the microVEGA FC is shaped in the single-digit micrometer range and moves continuously over semiconductor chips. During this motion, the laser selectively processes defined microstructures of several dies. This trimming process adjusts the resistance value in individual IC chips to a target value.

The small size of the dies' structures (approximately 1-2 micron) and the resulting extremely high demands on the three-dimensional positioning accuracy of the laser spot in relation to the structures place the highest demands on the machine hardware. The microVEGA FC includes an integrated measuring technology to achieve 100-percent process control, overcoming a particular challenge in semiconductor laser-trimming applications. The microVEGA FC system features fully automatic handling for 200-mm and 300-mm wafers. At process speeds of up to 400 mm/s, the system achieves a positioning accuracy of ±200 nm (at 3 Sigma).

Infineon plans to begin manufacturing analogue/mixed-signal technologies and power semiconductors in Dresden's Smart Power Fab in the fall of 2026.

Both companies share a goal of installing 3D-Micromac AG's laser-trimming systems at more of Infineon's production sites.