PI revs up motor drive offering

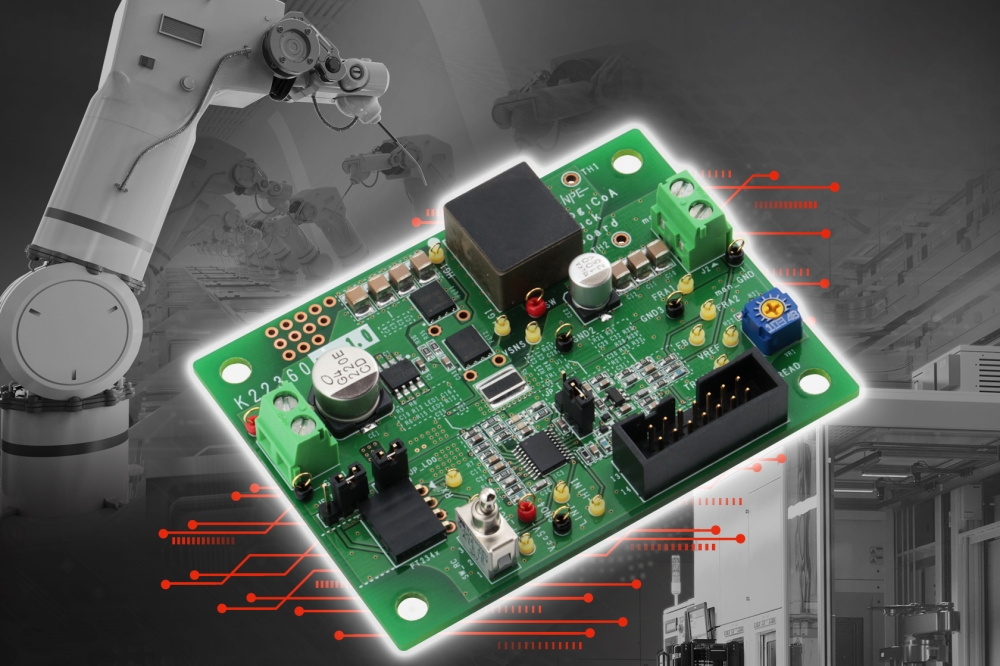

Power Integrations has enhanced its hardware-software bundle for brushless DC motors (BLDC) with BridgeSwitch-2, a new high-voltage integrated half-bridge (IHB) motor-driver IC family targeting applications up to 1 HP (746 W).

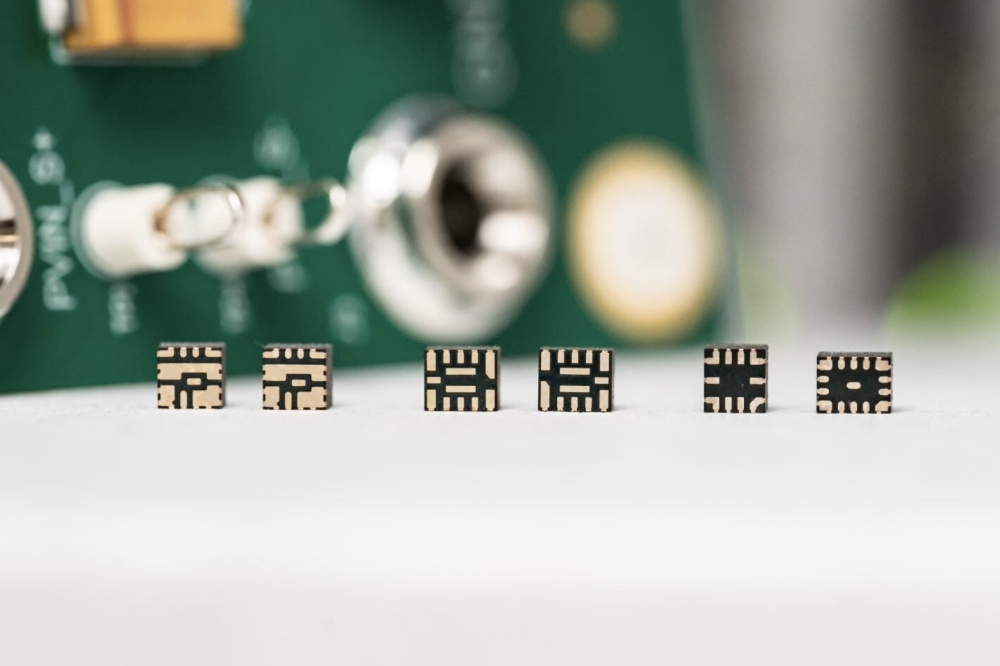

The new ICs, which feature high- and low-side drivers and advanced FREDFETs with integrated lossless current sensing, deliver inverter efficiency of up to 99 percent. The IHB architecture is designed to eliminates hot spots, which increases design flexibility and reliability, slashes component count and saves PCB area.

BridgeSwitch-2 is supported by Power Integrations’ MotorXpert software suite which includes single-phase trapezoidal control and three-phase sensor-less Field Oriented Control (FOC) modules, speeding inverter development.

BridgeSwitch-2 ICs handle operational exceptions in hardware, which permits the use of IEC 60730 Class A safety software, reducing certification time by months. Quiescent BLDC inverters can be ordered into sleep-mode, reducing driver power consumption to less than 10 mW; this leaves more power available under regulated standby power limits to be allocated for loads such as network access and monitoring.

Cristian Ionescu-Catrina, product marketing manager at Power Integrations, said: “The low standby consumption of BridgeSwitch-2-based motor drives enables designers to meet new and emerging EU ERP regulations. BridgeSwitch-2 ICs are also far more efficient than IGBT based IPMs across the entire load range.”

He continued: “From startup to performance optimisation, the GUI-based tool, terminal emulator and MISRA C-compliant code library of MotorXpert greatly simplifies the design process, allowing the motor architecture to be optimised in real-time without repeated firmware updates. BridgeSwitch-2 is microprocessor agnostic, easing its adoption into existing systems – this is important as engineers update designs to meet more stringent standby regulations.”

BridgeSwitch-2 ICs address a power range of 30 to 746 W (1 HP), encompassing a broad range of applications including heat exchanger fans, refrigerator compressors, fluid and circulation pumps, gas boiler combustion fans, washing machine drums and kitchen blenders and mixers.

The IHB architecture reduces component count by 50 percent and PCB space by 30 percent over discrete designs by eliminating shunt resistors and associated signal conditioning circuits. Shunt losses are also eliminated, improving efficiency. Precise motor control is achieved with the built-in real-time reporting of phase current (IPH) information. Accurate turn-on/off gate drive and a soft-body diode result in a typical EMI profile 10 dB lower than existing drivers, so a smaller EMI filter can be selected.

BridgeSwitch-2 ICs feature built-in DC overvoltage protection and current limits that protect the inverter and the system without relying on system software. The choice of error-flag or comprehensive fault bus reporting supports a range of system requirements.

Emerging use-cases like failure prediction are now possible with the high accuracy of the built-in IPH information and comprehensive reporting via the fault bus. BridgeSwitch-2 motor drives use built-in, hardware-based low- and high-side over-current protection to meet IEC 60335-1 Class A requirements. BridgeSwitch-2 also works without an auxiliary power supply, further reducing PCB area and component count.

Pricing for BridgeSwitch-2 ICs starts at $0.48 for 10,000-unit quantities. A 150 W reference design and design report, RDK-974 can be freely downloaded.