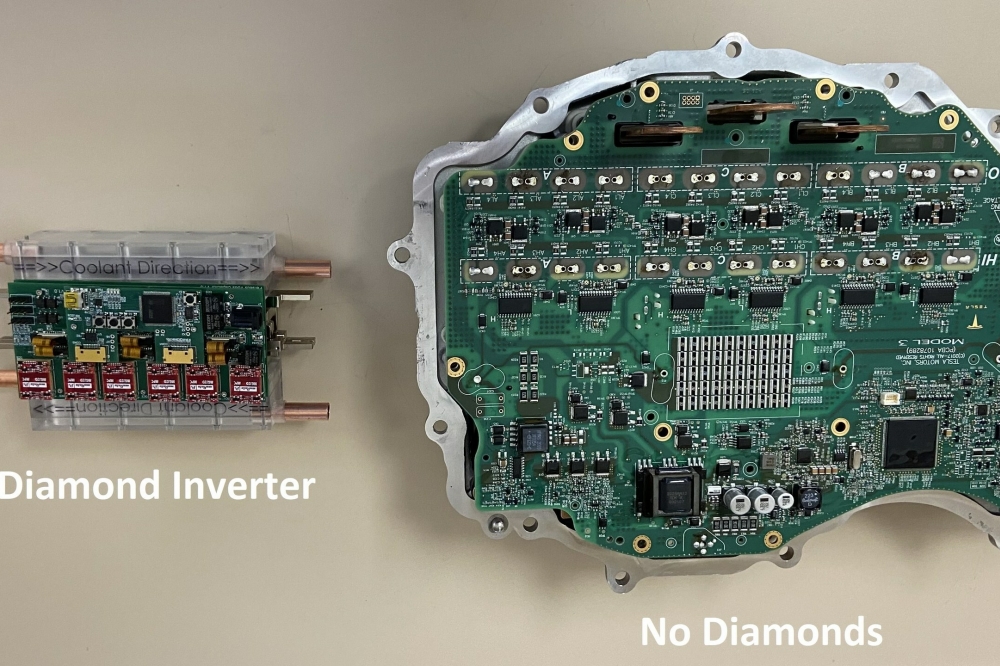

Diamond Foundry shrinks EV inverters

Power electronics unit is six times smaller than that of a Tesla 3

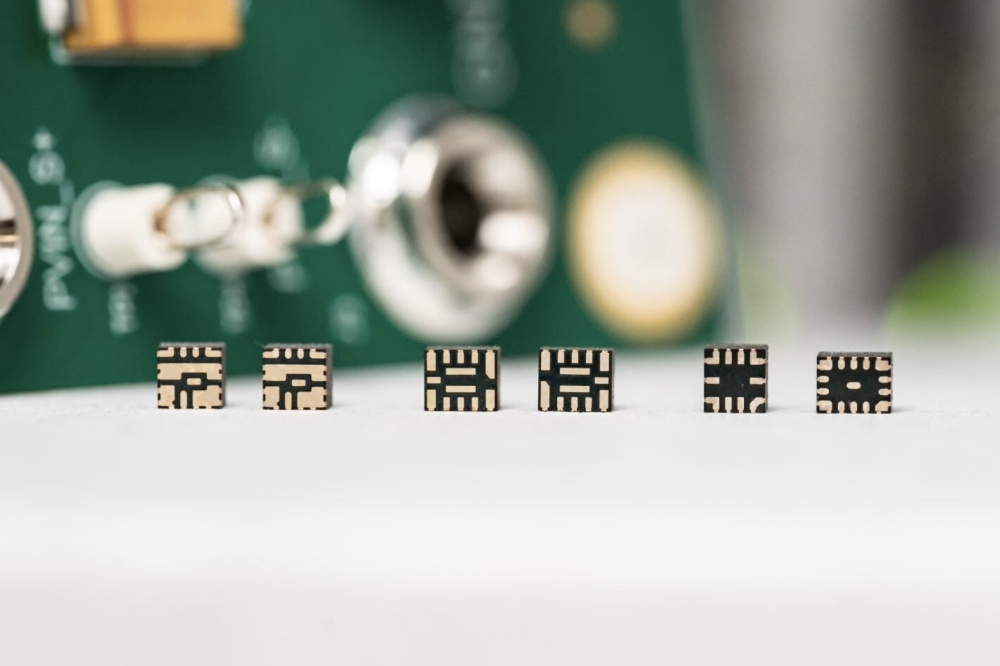

Diamond Foundry has created a 250W EV inverter based on its diamond wafer technology, with a power electronics unit six times smaller than that of a Tesla 3.

The company, which has its HQ in California, says the solution also delivers power more efficiently, thanks to a smart design enabled by diamond wafers in composition with established SiC dies.

Overall, the new 250W DF Perseus inverter use 18 SiC chips, occupies a volume of 0.46 litres and has a power density of 500KW/L In comparison, a Tesla 3 inverter has 96 SiC chips, occupies 28 litres, and has a power density of 9KW/L.

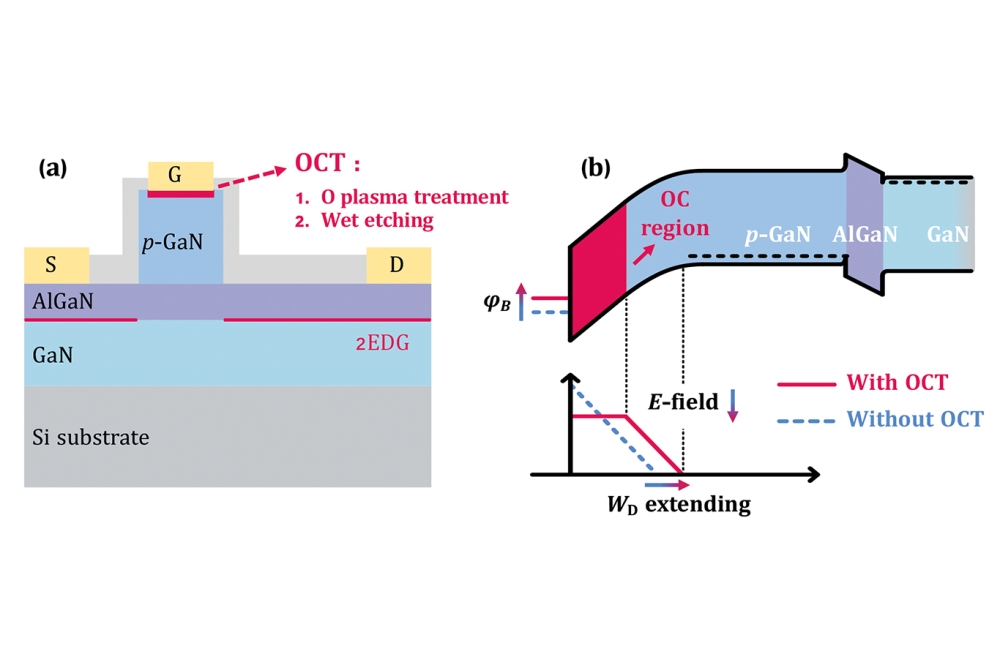

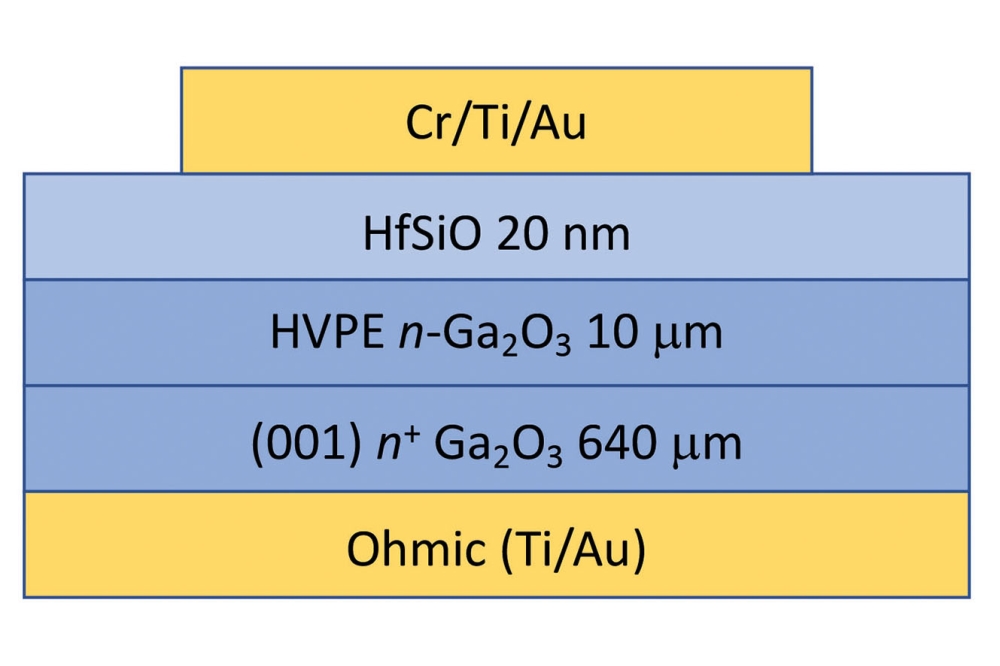

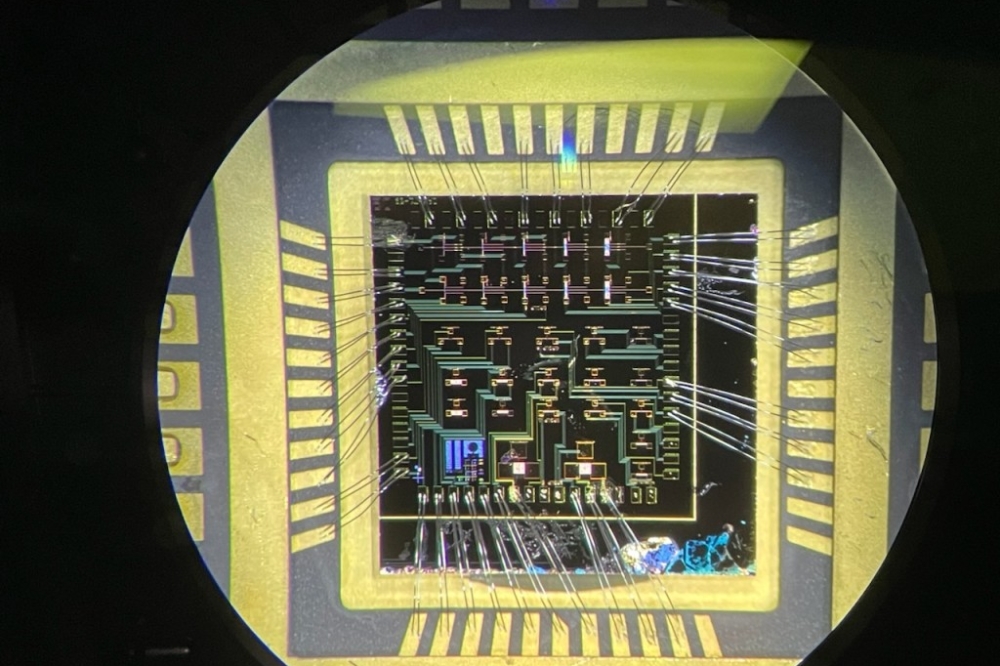

Power semiconductor design is driven by thermal conductivity ( the path to cool them dow) and electrical conductivity (the path to carry high currents). The thermal path has always been a challenge. To add to the problem, power semiconductors need to be isolated because of the high voltages – and voltage isolation barriers have poor thermal conductivity.

The company says that advent of cost efficient diamond wafers overcomes these issues by enabling extreme thermal performance plus extreme electrical insulation.