Magna-Power introduces thermal paste

Pitel Paste is formulated to achieve a balance between thermal, electrical and rheological properties

Magna-Power Electronics, a US-based maker of programmable DC power supply and electronic loads, has introduced Pitel Paste, a high-performance thermal paste for use in power electronics applications.

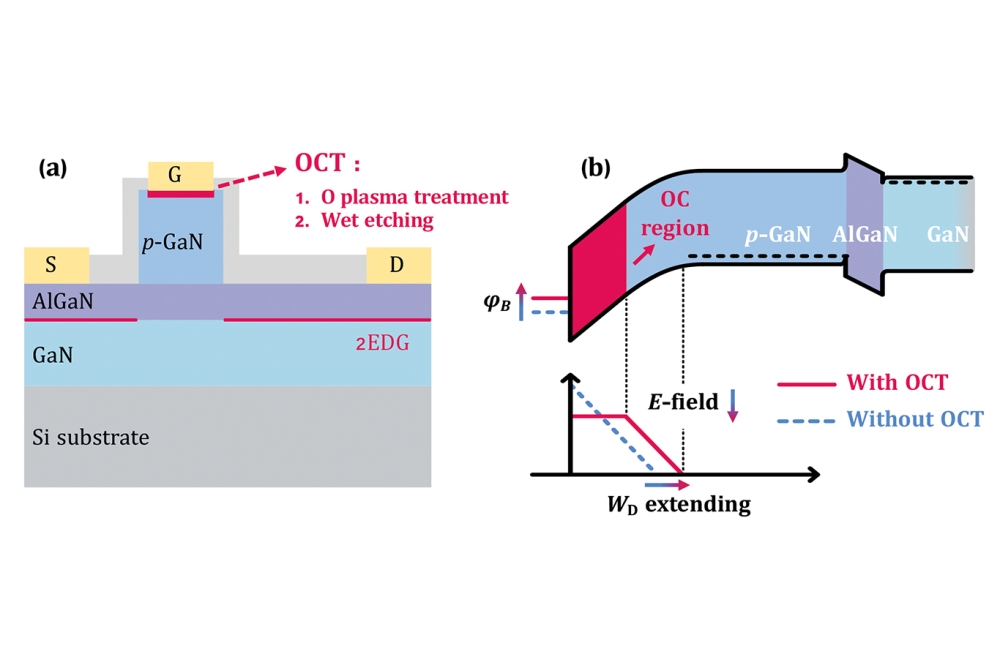

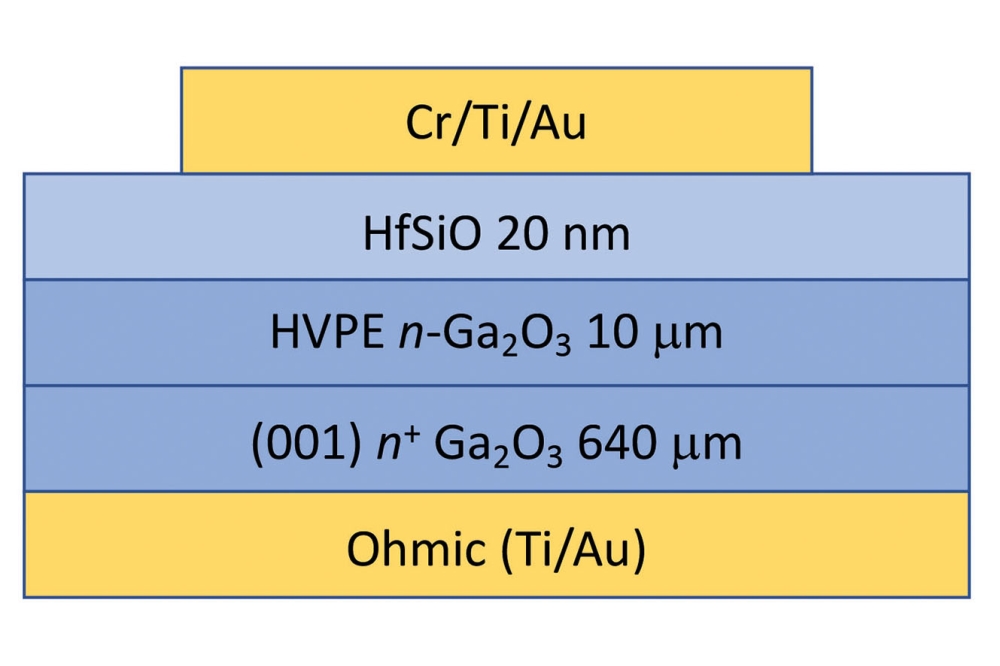

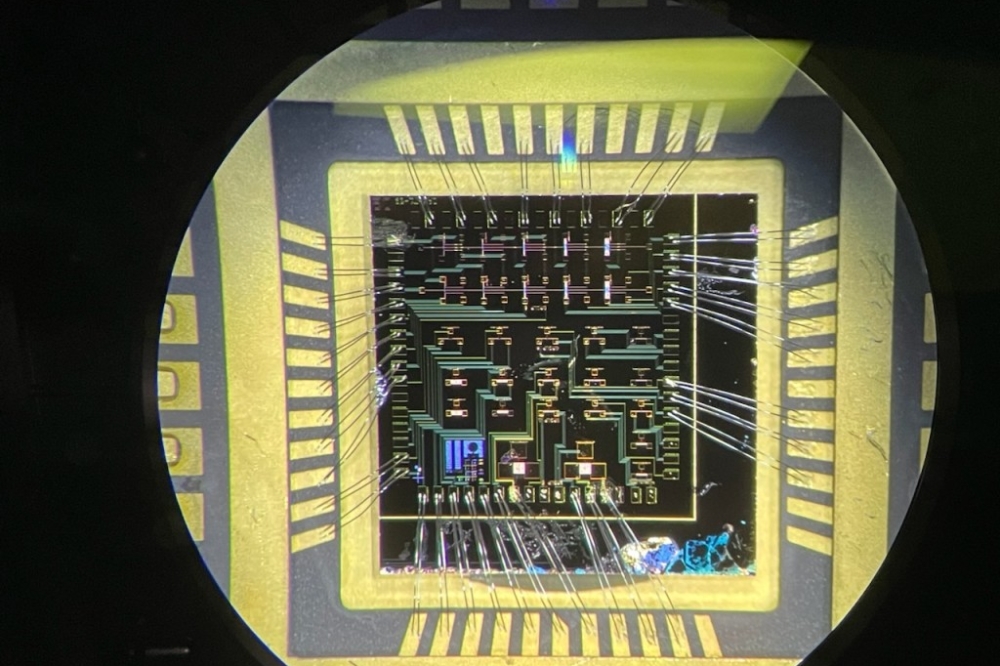

A thermal interface material between two metal surfaces can offer up to two orders of magnitude drop in thermal resistance. With higher power densities afforded by new GaN and SiC wide-bandgap semiconductors, thermal transfer considerations in power electronics are more crucial than ever.

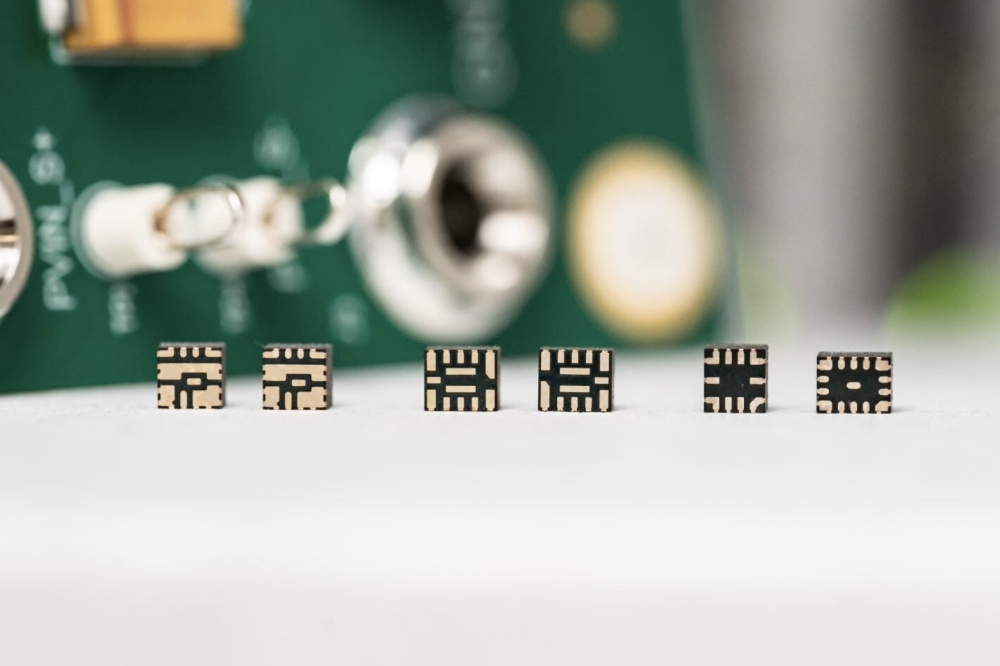

The first formula introduced, Pitel Paste AZ-01, is available in seven different containers ranging in volume from 1 ml to 19,000 ml. Syringe, container, and tube packaging is available to support various dispensing methods.

A lower thermal resistance allows product designers to achieve greater power densities by providing better transfer of heat from power semiconductors to the heatsink.

“Pitel Paste has been formulated to achieve the ideal balance between thermal, electrical and rheological properties,” said Stan Jaracz, a senior chemical engineer at Magna-Power Electronics. “It is the perfect thermal interface material for all application methods from spatula to stencil, providing excellent thermal transfer properties, with a packaging portfolio that tailors Pitel Paste for many electronics manufacturing processes."

Through a series of white papers, Magna-Power will be sharing its thermal paste technical experience and application techniques. The first white paper, titled Thermal Paste Surface Application in Power Electronics Manufacturing, is now available and discusses various dispensing methods, with considerations for automation, volume precision, placement precision and setup costs.