GE and US Army Research Lab partner on SiC thermal management

GE will use ARL developed ParaPower tool to aid the design of an advanced cooling technology for SiC wide band-gap devices

GE Research has announced a new collaboration with the US Army Research Laboratory (ARL), based in Adelphi, MD, to co-develop a next generation thermal management solution for SiC pulsed Wide Band-Gap Power Devices.

This collaboration will use co-design methodologies and tools to significantly improve the sise, weight, and performance of SiC power electronics systems to support more electrified vehicles and other systems for the Army.

SiC devices are playing an important role for improving the efficiency and performance of power electronics but can face thermal challenges that prevent their full capabilities from being used.

A multi-disciplinary project team from GE Research and ARL with expertise in thermal management, electronics packaging and materials research will co-develop PICCO, a potentially breakthrough thermal management solution using co-design and additive manufacturing that will allow for maximum efficiency and performance with these types of advanced power devices.

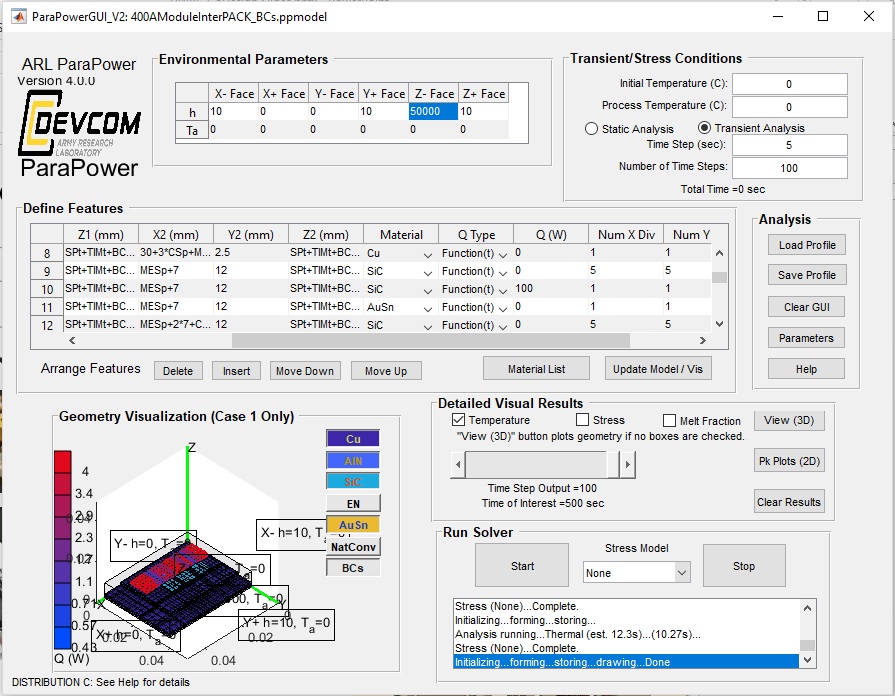

The project team is using the open source ARL ParaPower tool, which was developed by ARL to accelerate the design and deployment of a wide range of electronic packaging and thermal management solutions for the Army.

GE’s Peter de Bock, a principal engineer for ThermoSciences and project leader, said the GE Research team is excited to work with ARL on their open source platform, stating, “We’re particularly excited to see how ARL ParaPower can help us bring together multiple research domains to accelerate the co-development of our PICCO technology. Implementation of PICCO has the potential to enable new levels of capability in advanced more electrified vehicles and other systems that the Army is looking to realise.”

Dr. de Bock said that applications such as more electrified vehicles’ drive systems require power electronics cooling systems to manage occasional short duration high power events that have the potential to cause an undesired rapid increase in temperature of the SiC power device. The PICCO project will focus on development of a thermal management innovation that increases the thermal inertia of the power electronics package, improving the package thermal performance such that the full capability of the SiC devices can be used.

The project team is looking forward to maturing the PICCO technology towards demonstration and validation in a power module and eventually applying it to an Army relevant system.