Bosch poised for leap in e-mobility technology

The new microchips made of silicon carbide (SiC) that Bosch has developed will help electromobility make a great leap forward. In the future, the chips made of this extraordinary material will set the pace in the power electronics – the command centre for electric and hybrid vehicles.

Compared to the silicon chips used to date, SiC semiconductors have better electrical conductivity. This enables higher switching frequencies while also ensuring that much less energy is dissipated in the form of heat. Bosch manufactures the new generation of semiconductor chips at its Reutlingen plant, 25 miles south of Stuttgart. At this plant, the company has been turning out several million microchips every day for decades.

Semiconductors made of silicon carbide set new standards for switching speed, heat loss, and size. It all begins with additional carbon atoms, which are introduced into the crystalline structure of the ultra-pure silicon used to manufacture semiconductors. The chemical bond created in this way turns the semiconductor chips into real powerhouses. Especially for applications in electric and hybrid vehicles, this means many advantages.

In power electronics, they ensure that 50% less energy is lost in the form of heat. This saving translates into more efficient power electronics and more energy for the electric motor and therefore for the battery range. Motorists can drive 6% further on a single battery charge. In this way, Bosch is addressing one of the stumbling blocks for potential buyers of electric cars: nearly one in two consumers (42%) decide against buying an electric vehicle because they are afraid the battery will run out while they are on the road. In Germany, this anxiety is even more prevalent, affecting 69% of consumers. Alternatively, car manufacturers can make the battery smaller for a given range. This reduces the cost of an electric car’s most expensive component, which in turn reduces the vehicle’s price.

The reason is that the new technology also offers further potential savings down the line: the much lower heat losses of the chips, combined with their ability to work at much higher operating temperatures, mean that manufacturers can cut back on the expensive cooling of the powertrain components. That has a positive impact on electric vehicles’ weight and cost.

With this silicon carbide technology, Bosch is systematically expanding its semiconductor know-how. The company will be using the SiC semiconductors in its own power electronics in the future. For its customers, this brings together the best of both worlds, as Bosch is the only automotive supplier that also manufactures semiconductors.

“Thanks to our deep understanding of systems in e-mobility, the benefits of silicon carbide technology flow directly into the development of components and systems,” said Harald Kroeger, Member of the Bosch board of management. As one of the leading manufacturers of automotive semiconductors, Bosch has been exploiting this globally unique advantage for almost 50 years. In addition to power semiconductors, these include microelectromechanical systems (MEMS) and application-specific integrated circuits (ASICs).

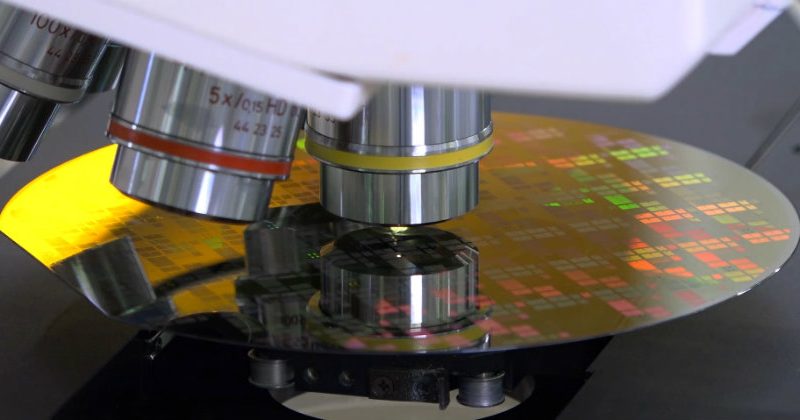

Turning the circular discs of silicon or silicon carbide – the wafers – into semiconductor chips involves an elaborate manufacturing process that can last up to 14 weeks. In several chemical and physical processes, the wafers acquire ultra-fine structures that will subsequently make up the tiny chips, each of which measures just a few millimetres.

In June 2018, Bosch laid the cornerstone for its state-of-the-art semiconductor factory in Dresden. Its manufacturing operations will use wafers with a diameter of 300 millimetres. This means significantly more chips from a wafer, and correspondingly greater economies of scale than with semiconductors based on 150- and 200-millimeter technology. Bosch produces the latter in Reutlingen, where it will also manufacture the new SiC chips. The wafer fabs in Reutlingen and Dresden complement each other perfectly. This enables Bosch to further strengthen its competitiveness.

“Semiconductors are a core component of all electrical systems. They are also turning data into a coveted raw material of the future. As they are becoming increasingly important in our fields of activity, we want to continuously expand our manufacturing operations,” Kroeger added.

In its wafer fab in Dresden, Bosch is investing around a billion euros – the largest single investment in the company’s history. In the factory, facilities are currently being installed in the clean room areas. The first associates are due to start work in the spring of 2020. Bosch will operate the plant as a carbon-neutral site.