Powercast Improves Power Harvesting Devices

The

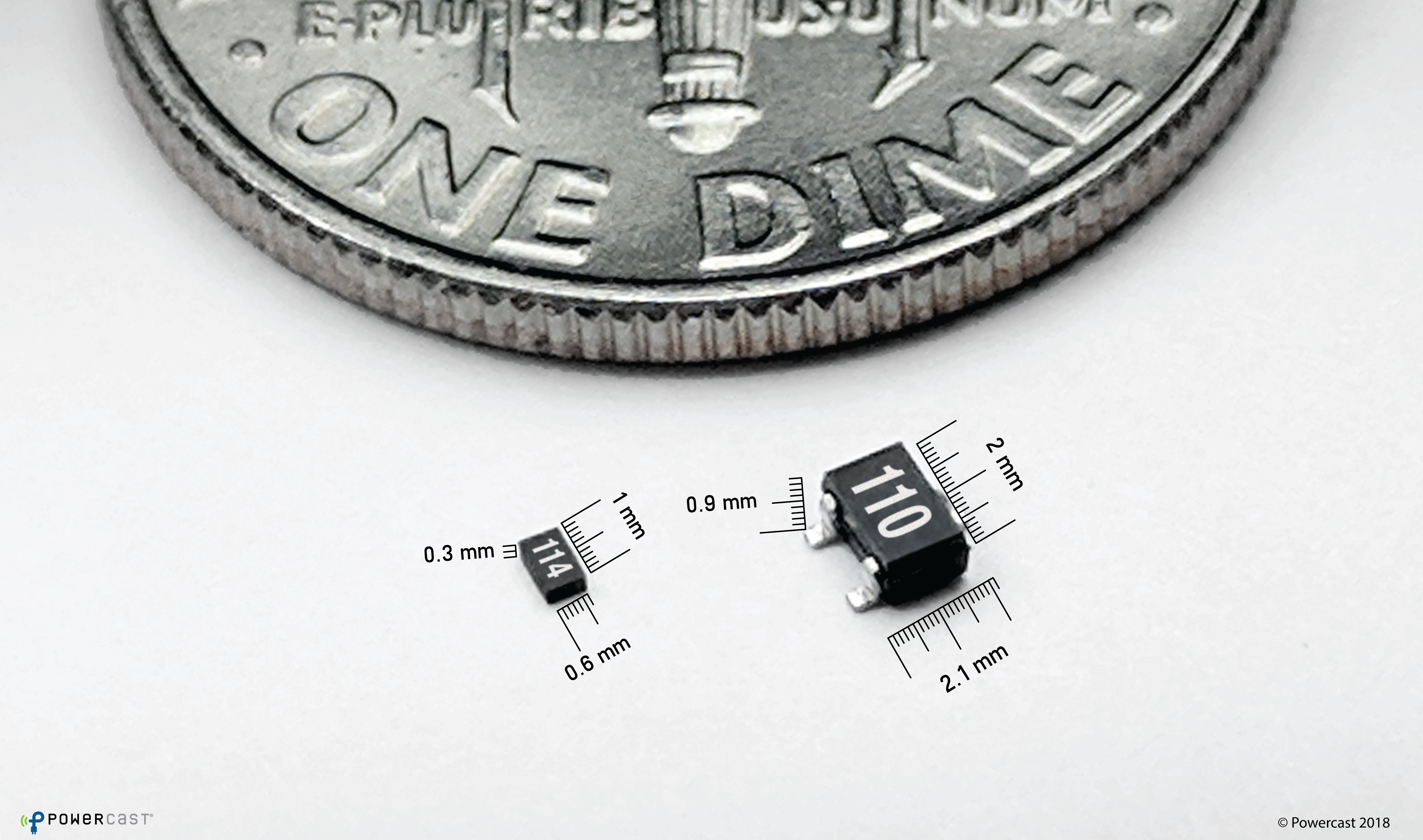

new PCC114 Powerharvester footprint is seven times smaller than Powercast's

existing device and has 20 times less volume, facilitating the design of

ultra-compact, wirelessly-powered devices.

Powercast Corporation has announced a smaller Powerharvester® wireless power receiver and RF-to-DC converter chip (PCC114) for its chipset, which consists of a wireless power receiver and complementary boost converter IC. The new device is designed for embedding in space-constrained consumer designs like smart cards or hearing aids.

The new chip builds on Powercast's existing Powerharvester receiver (PCC110), which has been deployed in industrial and commercial wireless power systems for seven years. Powercast used that experience to refine and reduce the size of its technology specifically for the consumer market. The new PCC114 receiver chip's footprint (1mm x 0.6mm x 0.3mm) is seven times smaller than the existing PCC110 (2mm x 2.1mm x 0.9mm) and has 20 times less volume, facilitating the design of ultra-compact, wirelessly-powered devices.

When a Powerharvester receiver (PCC114 or PCC110) is embedded in a device, it harvests the RF energy sent over the air from either an "˜intentional' or "˜anticipated' RF source, then converts it to DC current that can directly power a device without a storage battery or to recharge a device's batteries.

The company describes an "˜intentional' RF source as an RF transmitter in the home, office, public place or industrial setting, like Powercast's new FCC-approved PowerSpot® far field (up to 80 feet) transmitter. It creates a coverage area much like Wi-Fi and automatically charges enabled devices over the air when in range. Manufacturers can use the PowerSpot either in its standalone form or its subassembly for quick integration into their own products, or they can license Powercast's technology and design their own RF transmitter. PowerSpot tops off devices left on a countertop overnight in its charging zone, which varies with device type and power consumption. For example, power-hungry, heavily used devices like hearing aids, ear buds, game controllers, smart watches, fitness bands or headphones charge best up to two feet away; keyboards and mice up to six feet away; smart cards and TV remotes up to 10 feet away; and low-power devices like home automation sensors up to 80 feet away. Audible or visual alerts indicate when devices move in and out of the charge zone.

Powerharvester technology is also designed to work with "˜anticipated' RF sources, such as UHF (ultra-high frequency) RFID inventory readers or NFC (near field communications) POS readers that could charge devices at the interaction point. The Powerharvester chip can harvest energy from the RF source at close range (centimeters for NFC or a few meters for UHF RFID) to power the device and enable contactless payment, ticketing, or data-change transactions. For example, using a typical RFID reader, Powercast's Batteryless UHF Retail Price Tag can be changed electronically from two meters (6.5 feet) away, and its Multi-Sensor RFID Tags can be powered and read from ten meters (32 feet) away.

Wireless power harvesting can enable smart cards that can be recharged while in use, so they offer power-hungry features without running out of juice. Examples include advanced security components like a fingerprint sensor, ePaper displays that retain data like balances or one-time PINs even when outside the power field, and hotel door access cards, loyalty/gift cards, or subway passes that become reusable/reloadable.